Did you know that CNC (Computer Numerical Control) machining can achieve tolerances as precise as ±0.005 inches? This incredible capability has revolutionized manufacturing across a plethora of industries—from automotive and aerospace to medical devices and consumer goods. As companies strive to produce parts and components with ever-shrinking tolerances, understanding how to control CNC machining tolerances effectively becomes paramount.

In this comprehensive blog post, we will dive deep into CNC machining tolerances, explore the factors that influence them, and offer detailed solutions to manage and control them efficiently. By the end of this piece, you will understand not only what CNC machining tolerances are but also the best practices for maintaining them in your production processes.

What Are CNC Machining Tolerances?

Defining Tolerances

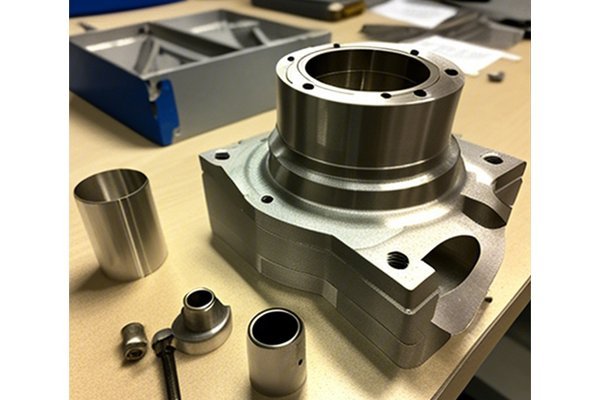

Tolerances refer to the allowable limits of variation in a physical dimension. In CNC machining, tolerances are critical because they ensure that parts fit and function properly in their intended applications. A tolerance defines a range around the nominal size of a feature. For instance, if a hole is specified to be 1.000 inches in diameter with a tolerance of ±0.005 inches, the actual diameter of the hole could be anywhere from 0.995 inches to 1.005 inches.

Why Tolerances Matter

CNC machining is often employed in applications where the precision of part dimensions is vital. Poorly controlled tolerances can lead to parts not fitting together correctly, which can ultimately result in failures, increased production costs, and delays. Therefore, understanding and efficiently controlling these tolerances is essential for achieving high quality and efficiency in manufacturing processes.

The Factors Affecting CNC Machining Tolerances

Several factors can influence the tolerances achievable in CNC machining. Here we would discuss some of the most critical aspects:

The type of material being machined can significantly affect tolerances. For instance, softer materials may allow for more machining flexibility, while harder materials often require more precise cutting tools and techniques.

The precision of cutting tools plays a significant role in achieving tight tolerances. Dull or worn-out tools can cause dimensional inaccuracies.

CNC machine settings, including speed, feed rate, and depth of cut, must be calibrated correctly. Adjusting these parameters can lead to differences in part dimensions.

Heat generated during machining can cause thermal expansion of both the workpiece and the machine components, leading to deviations in dimensions.

Regular servicing and calibration of CNC machines are essential to maintain accuracy. Out-of-calibration machines can lead to errors in dimensioning that affect tolerances.

The expertise of the machine operator is paramount. Skillful operators can adjust processes more effectively, leading to tighter tolerances.

Techniques for Controlling CNC Machining Tolerances

Now that we have established the factors affecting tolerances, let’s explore practical solutions and techniques to control CNC machining tolerances effectively.

Selecting the right material for your application is the first step in achieving desired tolerances:

Tool quality is essential in controlling CNC tolerances:

Fine-tuning your CNC machine settings can significantly impact part quality:

Controlling the machining environment can also help maintain tolerances:

Regular calibration is vital for maintaining CNC machine accuracy:

Incorporating advanced monitoring techniques can help companies identify and correct deviations in real-time:

Implement robust quality assurance practices to verify that final parts meet established tolerances:

Common Challenges in Achieving Tolerances

Even when implementing the best practices outlined above, manufacturers may encounter challenges that affect CNC machining tolerances:

In the world of CNC machining, maintaining tight tolerances is crucial for ensuring quality, functionality, and customer satisfaction. As explored throughout this blog post, several factors affect these tolerances—from material selection and tool quality to machine settings and calibration practices. Implementing robust control techniques and quality assurance practices will empower manufacturers to manage these tolerances effectively.

Understanding CNC machining tolerances is not merely an academic exercise; it has real implications for production efficiency, profitability, and product reliability. As the demand for precision manufacturing continues to grow, the strategies outlined in this blog offer actionable insights that can make a significant difference.

Whether you are a seasoned manufacturer looking to refine your processes or a newcomer to CNC machining, recognizing the importance of controlling tolerances is essential for success in today’s competitive landscape. By adopting these practices, you set your operation on the path to high-quality production that meets and exceeds customer expectations.

As we conclude, remember: the quest for precision in CNC machining is an ongoing journey that requires continuous learning, adaptation, and diligence. Keeping your finger on the pulse of tolerance management will not only contribute to your success—it will also position your company as a leader in the industry.