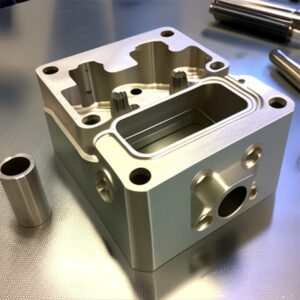

If you’ve ever worked on a CNC machining project involving aluminum, you’ve probably encountered the concept of R corners or radius corners. As a key part of part design, especially when precision and aesthetics are critical, knowing the limitations and possibilities of CNC machining is crucial. So, just how small can you go when it comes to the R corner radius on an aluminum part?

In this article, we’ll take a deep dive into the topic, answering this very question by examining the factors that determine the smallest R radius achievable during CNC machining. Along the way, I’ll share insights from my own experience working with CNC machining for over a decade, offering a practical perspective on what you can expect when designing your own parts with small R corners.

What is an R Corner in CNC Machining?

First things first—let’s clarify what we mean by R corner or radius corner. In CNC machining, when a part is designed, corners are often not created as sharp 90-degree angles. Instead, these corners are given a radius or roundness to ensure smoother transitions, reduce stress concentration, and improve the part’s durability and appearance.

The R corner refers to the radius of the arc that forms the rounded corner. It is represented by the letter R followed by the specific size of the radius. For example, an R1 would mean a corner with a radius of 1mm, while R0.5 would indicate a radius of 0.5mm.

Now, the real question is: how small can you go with the radius when machining aluminum?

Factors Affecting the Minimum R Corner in Aluminum CNC Machining

Achieving a very small R corner on an aluminum part depends on several factors, including tool size, machine precision, material characteristics, and tooling setup. Let’s break down each of these factors:

1. Tool Size and Geometry

The tool you use for CNC machining plays a significant role in how small of a radius you can achieve. The smaller the radius, the smaller the cutter required. However, smaller cutters tend to be more fragile, and they may not be able to achieve the same level of precision as larger cutters.

- End mills: The size of the end mill is one of the key factors in achieving smaller R corners. A small-diameter end mill, such as a ball-end mill, can be used to cut smaller radii, but there are limits to how small these tools can go.

- Precision: CNC machines can use ball-end mills with diameters as small as 0.1mm to cut corners with very small radii. However, the precision and sharpness of the tool are essential to getting clean, accurate cuts.

2. Machine Precision

The CNC machine itself must be capable of holding extremely tight tolerances to achieve a very small radius. High-precision CNC machines can achieve radii as small as 0.1mm, but the machine’s rigidity, control system, and ability to handle small cutter tools effectively are all factors that contribute to the quality of the result.

- Tolerance capabilities: Most modern CNC machines, especially 3-axis and 5-axis CNC machines, can achieve very tight tolerances, allowing you to create radii that are incredibly small and accurate.

- Spindle speed: Faster spindle speeds and high feed rates allow the tool to move more efficiently, which is especially important when working with small radii to prevent tool wear and maintain precision.

3. Material Characteristics of Aluminum

Aluminum is a versatile material for CNC machining and is known for its machinability. However, the specific alloy of aluminum used can affect the minimum achievable R corner radius.

- Alloy types: Aluminum alloys like 6061 and 7075 are commonly used in CNC machining. While both have excellent machinability, 7075 aluminum, for example, is much stronger and may be harder to machine, making achieving small R corners more challenging.

- Surface finish: When cutting aluminum, achieving a smooth surface finish with small radii requires careful adjustment of cutting speeds, feeds, and cutting tools to avoid tool marks or a rough finish.

4. Tooling Setup and Cutting Strategy

The way you set up the CNC machine and the cutting strategies employed are key in achieving small R corners. Specific techniques are often used to cut very small radii, such as:

- Multiple passes: In many cases, it’s necessary to make several passes with the cutter to achieve the desired R corner radius. This is particularly true for small radii to ensure that the cut is accurate and smooth without stressing the material too much.

- Climb milling: In climb milling, the cutting tool rotates in the same direction as the feed, which can result in smoother finishes and greater precision when cutting small features like R corners.

The Smallest R Corner Achievable on Aluminum CNC Parts

Now that we’ve looked at the factors influencing small R corners, let’s talk about what is actually achievable in aluminum CNC machining.

Typical Minimum R Corner Sizes

In CNC machining, especially when working with aluminum, the smallest R corner you can expect typically depends on the following:

- Small R Radius with Ball-End Mills:

- The smallest R corner you can typically achieve with a ball-end mill is around 0.1mm to 0.2mm, depending on the CNC machine’s precision and the quality of the tooling.

- For extremely fine, precise parts, some high-precision CNC machines can achieve 0.05mm radius corners. However, this level of precision requires top-tier tools and a very rigid machine setup.

- Practical Limits for Production:

- In a typical manufacturing scenario, the most common R corners used are in the range of 0.5mm to 1mm, as they are easier to achieve with standard tooling and equipment.

- Going beyond 1mm is typically more straightforward and less risky in terms of tool wear and part quality.

Precision CNC Machines vs. General Machines

- Precision machines: High-end machines, such as 5-axis CNC machines, can push these limits further and make corners with radii as small as 0.05mm, but this requires advanced setups, and it’s not always necessary unless you’re working in industries that require extreme precision, such as aerospace or medical device manufacturing.

- General-purpose machines: For most standard CNC machines, achieving radii smaller than 0.5mm can become difficult and may result in a rougher finish or more tool wear.

Real-World Application: What Can You Expect for Your Parts?

If you’re working with a manufacturer, you might be wondering: what does this mean for my specific CNC machining project?

- For Prototypes: If you’re designing a prototype with small radii, it’s essential to communicate with your CNC machining provider about the limits of their equipment. For most prototypes, a radius of 0.5mm to 1mm is perfectly achievable and won’t increase costs significantly.

- For Production Runs: If you’re planning a production run, the smallest achievable radii will depend on the volume and the level of detail required. In production, you’ll often find a radius between 0.5mm and 1mm is most common.

Conclusion: Achieving Small R Corners with Aluminum CNC Machining

When designing parts with CNC machining, it’s crucial to consider the smallest R corner achievable for your project. The R corner radius depends on several factors, including the tool size, machine precision, material type, and cutting strategies.

In most cases, 0.5mm to 1mm is achievable with standard CNC machines and tools, while 0.1mm to 0.2mm radii are possible on high-precision setups. However, for most production needs, achieving R corners with a radius of 0.5mm to 1mm is both practical and cost-effective.

At YL-Machining, we specialize in CNC machining of aluminum parts, and we can work with you to ensure your parts meet the required precision—whether you’re aiming for small radii or intricate, custom designs. Need help figuring out the best machining strategy for your next project? Let’s discuss how we can bring your design to life with the right CNC machining process.

-300x225.jpg)