: Did You Know?

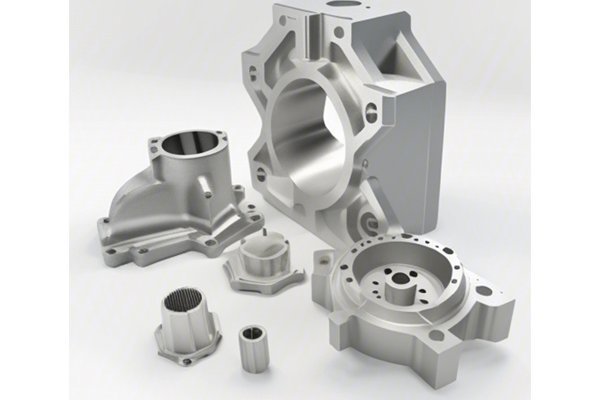

Did you know that aluminum is the most widely used non-ferrous metal on the planet? With exceptional properties such as lightweight, corrosion resistance, and excellent machinability, aluminum alloys have become essential in numerous industries from aerospace to automotive. Among these alloys, 5052 and 6063 have gained prominence, especially in the realm of CNC machining. But what makes these two alloys distinct in terms of forming performance? This comprehensive blog delves deep into the nuances of 5052 aluminum and 6063 aluminum, exploring their characteristics, applications, and the underlying reasons for their differing performance.

—

Chapter 1: to Aluminum Alloys

Aluminum alloys are categorized into two primary classifications: wrought and cast. Wrought alloys are mechanically worked into the desired shape, while cast alloys are poured into molds. Within the wrought category, aluminum alloys are designated by a four-digit code. For instance, 5052 and 6063 belong to the 5000 and 6000 series, respectively.

Chapter 2: Key Characteristics of 5052 Aluminum

5052 aluminum is known for its excellent corrosion resistance, high fatigue strength, and moderate to good weldability. Below are its instrumental properties:

These attributes make 5052 suitable for applications where strength, corrosion resistance, and weldability are paramount, such as marine environments, automotive fuel tanks, and various consumer products.

Chapter 3: Key Characteristics of 6063 Aluminum

6063 aluminum, commonly referred to as architectural aluminum, is prized for its excellent extrudability and good surface finish. Its salient properties include:

This alloy is often utilized in structural applications like window frames, irrigation tubing, and architectural fittings due to its aesthetic finish and resilience.

Chapter 4: Comparing the Forming Performance of 5052 and 6063 Aluminum

Forming performance in metalworking relates to how easily an alloy can be shaped without defects like cracking or warping. Here, we explore how 5052 and 6063 stack up against each other:

Chapter 5: Practical Applications

Understanding the differences in forming performance aids in the decision-making process for manufacturers. Here are key applications for each alloy:

Chapter 6: Selection Criteria and Future Performance

When selecting between 5052 and 6063, one must consider the application, environmental conditions, and cost-effectiveness. Crucial factors include:

Chapter 7: CNC Machining Techniques for Each Alloy

CNC Machining of 5052 Aluminum:

CNC Machining of 6063 Aluminum:

Chapter 8: Environmental Considerations

Both alloys exhibit excellent corrosion resistance, but specific environmental factors may affect their longevity:

: Choosing the Right Alloy for Your CNC Machining Needs

In conclusion, understanding the differences in forming performance between 5052 aluminum and 6063 aluminum is essential for optimizing CNC machining results. Factors like mechanical strength, weldability, and machinability not only influence the performance of the end product but also have implications for manufacturing processes and costs.

As you navigate the selection process for CNC machining, consider the unique requirements of your application and how each alloy aligns with your operational goals. Grasping these differences and their implications will not only enhance your production efficiency but also help sustain high-quality outputs.

Remember, the choice between 5052 and 6063 isn’t just a matter of preference—it’s about selecting the right material to ensure long-term success and reliability in your applications. We hope this blog has equipped you with the insight you need to make informed decisions in your future CNC machining projects.