Did you know that stainless steel accounts for approximately 25% of the total steel production in the world? It’s a material prominently used in a variety of industries, thanks to its strength and resistance to environmental degradation. Among stainless steel grades, 316 and 2205 have gained substantial attention, particularly in applications involving CNC turning. In this comprehensive blog, we will delve into the differences between the corrosion resistance of 316 stainless steel and 2205 stainless steel when subjected to CNC turning operations.

The importance of corrosion resistance cannot be overstated—damage from corrosion not only impacts the structural integrity of metal components but can also lead to significant financial losses in repair and replacement, as well as safety hazards.

Understanding the Basics

What Is CNC Turning?

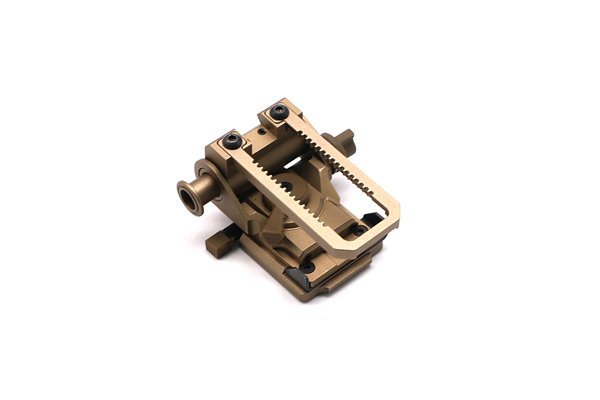

Computer Numerical Control (CNC) turning is a manufacturing process that involves the rotation of a workpiece against a cutting tool. This operation can be used to create cylindrical parts with precision and accuracy. It is an essential process in industries ranging from aerospace to automotive, where high-quality components are crucial.

An Overview of Stainless Steel Grades

Stainless steel is categorized into various grades based on its composition and resulting properties. Two prominent grades are 316 and

Comparison of Corrosion Resistance

Mechanisms of Corrosion

Corrosion occurs when the metal reacts with its environment, leading to the deterioration of material. Factors influencing corrosion include moisture, temperature, chemical composition of the environment, and the presence of stress.

316 Stainless Steel Corrosion Resistance

316 grade stainless steel shows remarkable resistance to various types of corrosion:

2205 Stainless Steel Corrosion Resistance

2205 offers superior performance in severe environments, thanks to its unique microstructure:

Application Scenarios

Marine Environments

Both 316 and 2205 stainless steels are often used in marine applications. However, 2205 would be preferable in highly corrosive marine conditions due to its superior pitting resistance.

Chemical Processing

In chemical industries where acidic or basic environments are prevalent, 316 is commonly used. However, for extremely aggressive chemicals, 2205 can offer longer durability.

Food Processing

In food applications, 316 is widely accepted because of its hygienic properties, while 2205 can be used where higher strength and improved corrosion resistance are required.

Consideration in CNC Turning

Machining Characteristics

When utilizing these stainless steels in CNC turning, it’s essential to note the following characteristics:

Surface Finish

Both stainless steels can achieve high surface finishes; however, special care needs to be taken with 2205 due to its higher hardness which may necessitate more precise handling and tooling.

Testing and Quality Control

Implementing rigorous testing and quality assessment methods is crucial for ensuring the chosen material’s suitability for its intended application. Common tests include:

s

In conclusion, understanding the differences in corrosion resistance between 316 and 2205 stainless steel is vital for industries reliant on CNC turning processes. While 316 stainless steel provides solid all-round performance, particularly in food processing and less aggressive environments, 2205 stainless steel offers superior corrosion resistance in severe environments, making it the ideal choice for applications prone to high stress and severe corrosion.

This blog has explored how these properties impact machining processes, surface finish, and quality control measures. As industries push towards higher reliability and efficiency, the choice of material becomes increasingly significant.

Why This Blog Matters

Choosing the right stainless steel for CNC turning applications requires a delicate balance of performance, cost, and operational conditions. Understanding the nuances in corrosion resistance between different stainless steel grades can lead to better material selection, enhanced durability of components, and ultimately, a more efficient manufacturing process. In an era where quality and performance are paramount, these insights will not only inform a better choice of materials but also play a key role in ensuring long-lasting product performance and reducing maintenance costs.

As you reflect on this information, consider the impact it can have on your own projects and operations. With the right knowledge, you can make informed decisions that bring both safety and economic advantages to your CNC turning endeavors.