Did you know that the choice of aluminum alloy can significantly influence the safety, efficiency, and durability of aerospace and automotive components? As industries heavily rely on advanced materials to meet stringent performance standards, understanding the differences between aluminum alloys has never been more critical. In this blog post, we’ll explore the essential differences in high-temperature resistance between two widely used aluminum alloys: 6082 and

Aluminum is inherently lightweight, corrosion-resistant, and easily machinable, making it a favored choice across various industries, including automotive, aerospace, construction, and marine. Aluminum alloys are classified into two major categories: wrought and cast alloys.

Both alloys are designated by a four-digit code system established by the Aluminum Association. The first digit indicates the primary alloying element. For instance, the “6” in 6082 denotes silicon and magnesium as alloying elements, while the “5” in 5052 indicates magnesium as the principal alloying element.

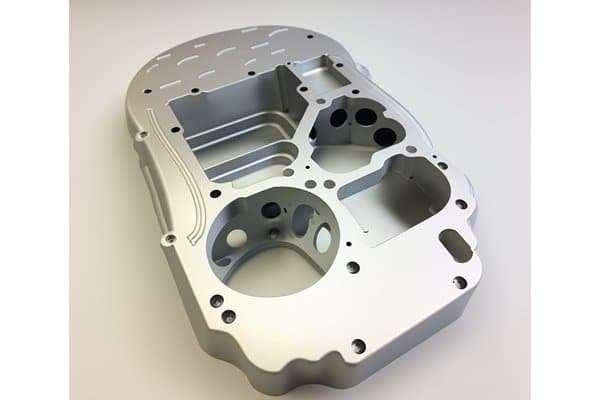

The 6082 alloy is a prominent choice among engineers due to its high strength and excellent corrosion resistance. It is mainly used in structural applications. Here are some key properties:

The 6082 alloy exhibits good high-temperature resistance, remaining stable and able to maintain its mechanical properties under temperatures up to 250°C (482°F). This characteristic makes it suitable for structural members in buildings, bridges, and other applications where elevated temperatures are a concern.

5052 aluminum, on the other hand, is known for its excellent corrosion resistance and workability. Below are its significant properties:

While 5052 exhibits reasonable high-temperature resistance with a maximum temperature limit of 120°C (248°F), it is primarily suited for use in applications requiring good workability rather than extreme heat conditions.

Performance Under Heat

When comparing the high-temperature resistance of 6082 and 5052 aluminum, it is essential first to understand not just the maximum operating temperatures but also how each alloy’s properties change when subjected to heat.

Applications in the Real World

Given their differences in high-temperature resistance, the choice between 6082 and 5052 depends on specific application needs:

Several factors go into choosing the right aluminum alloy for a specific application. Here are some critical considerations:

Performance Requirements

The specific mechanical and thermal performance requirements of your project will significantly influence your choice. If high strength and resistance to heat are required, 6082 is recommended. For applications with exposure to humidity and saltwater with moderate temperature ranges, 5052 will fit better.

Manufacturing Processes

The intended manufacturing process also plays a vital role in material selection. 5052 alloys are easier to weld and form compared to 6082, which could require more advanced temperature and pressure levels for successful shaping.

Cost Considerations

Budget constraints may also come into play, as the price of aluminum alloys can vary based on time and supply and demand factors. Generally, 5052 is less expensive than 6082 due to the simpler alloying process.

In summary, both 6082 and 5052 aluminum alloys offer distinct benefits and use cases depending on high-temperature resistance, mechanical properties, workability, and cost considerations. While 6082 excels in structural strength and heat resistance, 5052 provides better corrosion resistance and ease of fabrication.

Understanding these differences is not just an academic exercise; it impacts the safety, durability, and efficiency of products and structures in varied industries. Choosing the right alloy can lead to enhanced performance and reduced manufacturing costs, ensuring that projects stand the test of time in both aesthetics and structural integrity.

To maximize the effectiveness of your selection, it’s crucial to evaluate your project requirements against the properties of these alloys carefully. Consider all factors — including mechanical properties, environmental conditions, and financial constraints — before making a decision.

Choosing between aluminum alloys impacts not only the immediate application but also the long-term sustainability and functionality of the structures and components we create. In a world that constantly demands innovation in material science, staying informed about the capabilities of different materials is of utmost importance.