As a seasoned expert in CNC machining, particularly in the creation of custom mechanical keyboard casings, I’ve seen firsthand how important material selection is when crafting high-quality, durable, and visually appealing keyboard enclosures. If you’re in the process of deciding what material to use for your custom CNC mechanical keyboard, you’re likely weighing the pros and cons of different options. While there are numerous materials available, in this article, I’ll focus on one of the most popular and widely recommended materials: aluminum.

We’ll explore why aluminum is often regarded as the best material for CNC mechanical keyboard casings, its benefits, and how it compares to other materials like plastic, steel, and brass. By the end of this guide, you’ll have a clear understanding of why aluminum keyboard enclosures are a top choice for many enthusiasts and manufacturers.

1. Why Aluminum is the Best Choice for CNC Keyboard Casings

Let’s start with the basics. When it comes to CNC machining, aluminum stands out for its blend of strength, versatility, and lightweight properties. Whether you’re a hobbyist crafting your first custom keyboard or a professional looking to upgrade your product line, aluminum offers a host of benefits that make it ideal for mechanical keyboard casings.

Strength and Durability

Aluminum, especially alloys like 6061-T6, is highly durable and resistant to wear and tear. Unlike plastic, which can crack or chip under pressure, aluminum provides a solid, long-lasting enclosure that stands up to daily use and can withstand the weight of the mechanical switches, keycaps, and other components. This is particularly important for people who want their keyboards to last for years without compromising performance.

Lightweight Yet Sturdy

Aluminum is much lighter than materials like steel, making it a great option if you’re after a more portable mechanical keyboard. Despite its lightness, it retains excellent structural strength. So, you get the best of both worlds: a casing that is easy to handle without sacrificing durability.

Aesthetic Appeal

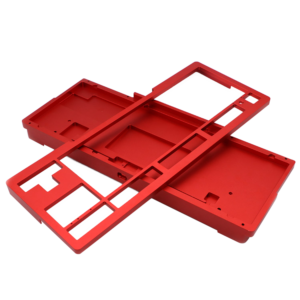

One of the standout features of aluminum keyboard enclosures is their visual appeal. Aluminum can be anodized, which adds a layer of protection while allowing for a variety of colors and finishes. Whether you prefer a sleek, minimalist matte black or a bright, vibrant anodized finish, aluminum offers endless customization possibilities that are hard to match with other materials.

2. Comparison of Aluminum with Other Common CNC Keyboard Casing Materials

Now, let’s compare aluminum to some other common materials used for CNC mechanical keyboard casings: plastic, steel, and brass.

Aluminum vs. Plastic

Plastic is often the go-to choice for budget-friendly keyboards due to its affordability and easy manufacturing process. However, plastic casings tend to feel flimsy and cheap, especially when compared to the sturdiness of aluminum. They are also more prone to cracking over time.

On the other hand, aluminum keyboard enclosures are much more robust and provide a premium feel. While plastic may offer a broader range of colors and textures, aluminum’s ability to be anodized provides a better finish that holds up longer under regular use.

Aluminum vs. Steel

Steel is another durable material that can be used for mechanical keyboard casings. However, it’s much heavier than aluminum, which can make the keyboard feel cumbersome and less portable. If you’re building a high-end mechanical keyboard for a more stationary setup, steel may be a solid choice due to its rigidity and weight. However, for most users who prioritize portability and aesthetics, aluminum remains the superior choice.

Aluminum vs. Brass

Brass is gaining popularity in the keyboard community due to its dense and premium feel. A brass keyboard case provides an incredibly solid and heavy feel, which some users love for its unique sound profile and tactile feedback. However, brass is much heavier than aluminum and can be prone to tarnishing over time if not properly cared for.

While brass does offer some unique qualities, aluminum is still a top contender because it balances weight, strength, and aesthetics without the maintenance hassles of brass.

3. The Benefits of Anodizing Aluminum Keyboard Casings

One of the main advantages of choosing aluminum keyboard enclosures is the ability to anodize the material. Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of aluminum. This not only enhances the material’s corrosion resistance but also opens up opportunities for customization with various colors and finishes.

Increased Durability

Anodizing creates a tougher surface on the aluminum, making it more resistant to scratches, scuffs, and general wear and tear. This process significantly improves the longevity of your keyboard casing.

Color and Finish Options

If you’re looking to create a keyboard that reflects your personality or brand, anodizing allows for a broad range of color options, from bright and bold hues to subtle, matte finishes. The anodized surface can be sealed to preserve the color and prevent fading over time.

4. Other Considerations When Choosing Material for CNC Keyboard Casings

While aluminum offers many benefits, there are a few additional factors to consider when selecting the best material for your CNC keyboard casing.

Cost

Aluminum can be more expensive than plastic, especially if you opt for high-grade alloys or specialized finishes like anodizing. However, given its durability and aesthetic appeal, many feel that the investment is worth it. Plastic may be cheaper upfront but might need to be replaced sooner due to wear and tear.

Sound Profile

The material of your keyboard case can affect the sound profile of your keystrokes. Aluminum provides a balanced sound—solid but not as resonant as steel or brass. Some enthusiasts prefer the acoustics of heavier metals like brass or steel, but for most users, aluminum strikes a perfect balance between acoustics and performance.

Weight and Portability

As mentioned earlier, aluminum keyboard enclosures are relatively lightweight compared to steel and brass, making them easier to transport. If portability is a priority for you, aluminum is likely the best material to choose.

5. Conclusion: Why Aluminum is the Top Choice for CNC Keyboard Casings

In summary, when it comes to CNC mechanical keyboard casings, aluminum offers the perfect combination of strength, lightweight design, aesthetic versatility, and durability. While other materials like plastic, steel, and brass have their merits, aluminum stands out due to its ability to balance all the necessary qualities that matter most to users: appearance, functionality, and performance.

If you’re in the market for a CNC keyboard casing and want a material that combines durability with style, look no further than aluminum. Whether you’re building your first keyboard or upgrading your existing one, aluminum’s qualities will ensure you end up with a product that not only looks fantastic but also performs excellently for years to come.

What do you think? Have you already decided on your material, or are you still debating between aluminum and other options? Share your thoughts in the comments below!