CNC machining is like the backbone of modern manufacturing, offering precision and efficiency in creating intricate parts and components. However, if you’re looking to tap into the world of CNC machining, one question likely looms large in your mind: “What’s it going to cost me?” Whether you’re a seasoned engineer or a curious newcomer, understanding the factors that influence CNC machining prices can help you make informed decisions. In this article, we’ll explore the ins and outs of CNC machining costs—think of it as your personal tour guide through this fascinating process.

Understanding CNC Machining and Its Importance

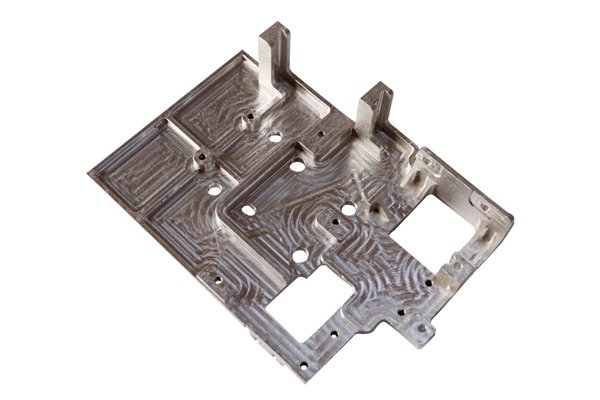

Before we dive into the price factors, let’s paint a picture of what CNC machining really is. Picture a robot arm working tirelessly to create metal or plastic parts with pinpoint accuracy—this is CNC machining! It stands for Computer Numerical Control, where machines are operated using computer programming. This meticulous process enables the production of complex shapes that can’t be achieved through traditional machining methods.

In today’s fast-paced industry, CNC machining is indispensable in fields ranging from aerospace to medical devices. But, what does all this mean in terms of costs?

Material Selection: The Weight of Costs

One of the heaviest factors on your wallet is material selection. Just like you wouldn’t buy a suitcase without considering whether you’re taking a weekend trip or moving across the country, you need to choose your materials based on your project requirements. Here’s the deal:

So, whether you’re crafting bicycle parts or aerospace components, the material you choose dramatically impacts the overall CNC machining price.

Technology and Equipment Costs

Next up is the technology and equipment costs. The machinery used in CNC operations varies from basic mills to sophisticated 5-axis machines. Each comes with its own price tag. Want precision? Be prepared to spend a little more:

It’s like choosing between a bicycle and a high-speed train. Both can get you places, but one comes with a significantly higher price for its added speed and efficiency.

Labor Costs: Skilled Hands on Deck

You might wonder, “Is labor really that big of a deal?” Absolutely! Skilled labor plays a crucial role in CNC machining. The experience and expertise of the technicians operating the machines can make all the difference:

So, remember that labor costs contribute significantly to the final price of your CNC projects.

Complexity of the Design: The More Intricate, The Costlier

Design complexity is another factor that can spiral the costs. Simpler designs are easier and quicker to manufacture, while complex specifications require advanced programming and longer production times. Here’s how it breaks down:

As the design complexity increases, expect the machined parts to come with a matching price tag.

Volume of Production: The More, The Merrier

Have you noticed that prices often come down with bulk orders? That’s because a larger production volume generally lowers the price per unit. There are few factors at play here:

So if you’re planning to produce thousands of identical parts, you’re in for a pleasant surprise when it comes to pricing!

Lead Times and Urgency: The Price of Time

Time is money, and this couldn’t be more true in CNC machining. If you’re in a hurry, be prepared to pay for the privilege:

Consider this like ordering dinner. If you can wait for delivery, you save money, but if you need it now, expect to pay a bit more for that immediate satisfaction.

Finishing Processes: The Cherry on Top

After CNC machining, parts often undergo finishing processes like coating, deburring, or polishing. Each of these adds extra costs, so let’s break this down:

Imagine it as getting a haircut; a simple trim costs less than a full-blown salon experience with color and styling.

Quality Assurance: Better Safe Than Sorry

Quality inspection is a non-negotiable factor in ensuring that parts meet required specifications. Investing in quality assurance can save you from costly errors down the line, but it does come with a cost:

Opting for thorough quality assurance processes might seem pricey at first, but it certainly pays off by preventing costly mistakes and ensuring product reliability.

Supplier Selection: The Balance of Trust and Cost

Lastly, don’t underestimate how the choice of supplier can affect pricing. Different shops offer various levels of service, quality, and pricing:

So ask yourself: Is it better to save a few bucks and risk delays or pay a bit more for peace of mind?

Conclusion: Key Takeaways for CNC Machining Costs

We’ve taken a deep dive into the myriad of factors that influence CNC machining prices. So, let’s summarize a few key takeaways:

Armed with this knowledge, you’re better prepared to navigate the world of CNC machining costs. Whether you’re talking to suppliers or planning your next project, understanding these factors can set you on the path to success.

Remember, knowledge is power—but it also gives you the confidence to negotiate and plan ahead. Happy machining!