When it comes to CNC prototyping, the choice of materials can make or break your project. Did you know that nearly 90% of design failures can be traced back to improper material selection? Choosing the right plastic materials not only affects the functional performance of your prototypes but also impacts the machining process, cost, and final product quality. In this comprehensive guide, we’ll explore the essential factors to consider when selecting plastic materials for CNC prototyping, along with expert insights, best practices, and technology trends shaping the industry.

Understanding CNC Prototyping

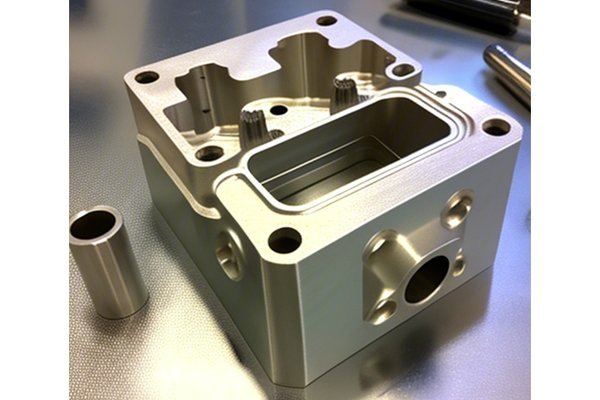

CNC (Computer Numerical Control) prototyping is a method that uses computerized control to operate tools and machinery, allowing for precise and repeatable manufacturing of parts. This technology has revolutionized industries by enabling rapid prototyping, which significantly reduces the time and costs associated with product development.

However, the success of CNC prototyping hinges on several critical factors, most notably the selection of suitable plastic materials. Let’s dive deeper into the aspects you need to consider.

Before delving into the specifics of material properties, it’s crucial to understand the intended purpose and application of your prototype. Consider the following questions:

Identifying the application’s requirements will help narrow down your material choices, ensuring that the selected plastics can withstand the intended use without compromising performance.

Mechanical properties are perhaps the most crucial factor to consider:

Understanding these properties will allow you to match a plastic’s performance characteristics with your project’s demands.

Not all plastics are created equal when it comes to machinability. Some materials may be more challenging to cut or shape, leading to increased wear on tools and longer production times. Here are some considerations:

While performance is key, availability and cost cannot be overlooked. The material you choose should be accessible in the quantities required for your prototype. Consider the following:

As sustainability takes center stage in manufacturing, considering the environmental impacts of your material choice is becoming increasingly important.

While functionality is paramount, many prototypes also need to look good. The aesthetic qualities of a material should align with the project’s vision:

Another often-overlooked aspect of material selection is the feedback from customers or stakeholders. Engaging them in the selection process can provide invaluable insights into performance expectations and preferences. Questions to ask might include:

Incorporating this feedback can lead to a more optimal material choice that aligns with end-user needs and expectations.

Choosing the right plastic materials for CNC prototyping is a multi-faceted task that requires careful consideration of various factors, including mechanical properties, machinability, cost, aesthetic qualities, and sustainability. Each factor plays a crucial role in determining whether a material will meet the demands of the project and contribute to its eventual success.

As industries continue to evolve, staying informed on trends in plastics and CNC technology is essential for designers and engineers. Remember, the right material selection not only enhances the prototype’s performance but can also lead to innovative products that stand out in today’s competitive market.

In a world where design failures can have significant repercussions, understanding the complexities of material selection is more important than ever. This knowledge empowers engineers and manufacturers to strategize effectively, ensuring that prototypes deliver on both design intent and functional requirements. As you embark on your next CNC prototyping project, keep this guide in mind, and make informed decisions that will set your innovations apart.