Opening:

Did you know that over 70% of engineering projects encounter delays during the prototyping phase? This statistic highlights a critical pain point in the manufacturing process that can significantly impact timelines and budgets. CNC (Computer Numerical Control) prototyping offers immense possibilities for innovation, but it isn’t without its challenges. By delving into the intricacies of CNC prototyping and understanding the common hurdles manufacturers face, we can uncover practical solutions to streamline processes and enhance product development efficiency.

—

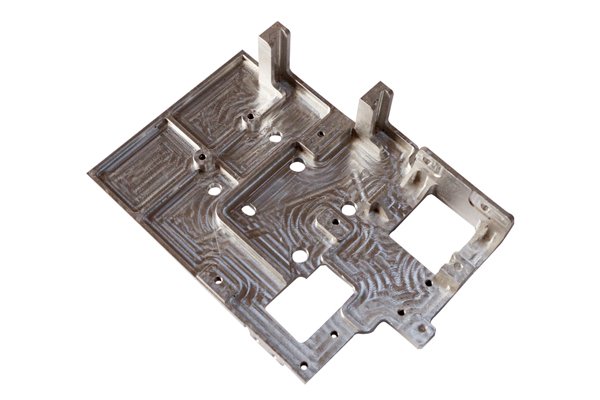

CNC prototyping is a subtractive manufacturing method that uses computer-controlled machines to create intricate shapes and designs from various materials. It allows manufacturers to produce precise, repeatable prototypes, making it a favored choice in numerous industries, from aerospace to automotive.

Despite its advantages, several challenges can impede the effectiveness of CNC prototyping. This blog will explore these common issues while presenting actionable solutions to ensure production remains smooth and efficient.

The Issue:

Choosing the right material for prototyping is crucial, as materials that perform well in one context may not be suitable in another. Factors such as mechanical properties, surface finishes, and thermal resistance play a significant role in determining the success of a prototype.

Solution:

The Issue:

Dimensional inaccuracy is a persistent challenge in CNC prototyping, often arising from machine calibration errors, tool wear, or parameter misconfigurations. This can lead to prototypes that do not meet design specifications, ultimately resulting in costly rework.

Solution:

The Issue:

Production times can extend due to numerous factors, including machine speed limitations and complex geometries that require longer machining setups. Extended production timelines can lead to missed deadlines and increased costs.

Solution:

The Issue:

Unplanned machine downtime due to equipment failure or maintenance can halt production. Since CNC machines are often the backbone of prototyping, any downtime can lead to significant delays.

Solution:

The Issue:

CNC prototyping can be expensive, driven by material costs, machine operation expenses, and labor requirements. Manufacturers constantly seek ways to reduce expenses without compromising quality.

Solution:

The Issue:

Prototypes often suffer from design flaws that make them difficult or impossible to manufacture efficiently. These flaws can become apparent only after production has started, leading to costly redesigns.

Solution:

The Issue:

Specialized skills are required to operate CNC machines and interpret the software intricacies of CAD and CAM (Computer-Aided Manufacturing). A lack of skills can be a barrier to effectively implementing CNC prototyping.

Solution:

The Issue:

Achieving the desired surface finish on prototyped parts is critical, especially in sectors demanding high standards for aesthetic and functional performance. Surface finish issues can arise from tooling, settings, or machining processes.

Solution:

:

Navigating the world of CNC prototyping presents both formidable challenges and exciting opportunities for manufacturers. By addressing key issues such as material selection, dimensional accuracy, prolonged production times, machine downtime, and cost constraints with comprehensive strategies, companies can enhance their prototyping process and drive innovation in product development.

As industries continue to evolve, the implementation of advanced technologies, regular training, and a focus on efficiency are paramount to remain competitive. As you experience your journey into CNC prototyping, remember that these challenges, though daunting, also present an opportunity for growth, learning, and improvement.

Final Thoughts:

Understanding and mitigating the common challenges of CNC prototyping is not just an operational necessity; it is a commitment to excellence in manufacturing. With proper strategies in place, you not only streamline your processes but also position your organization for success in today’s fast-paced market. Keep pushing the boundaries of what is possible with CNC prototyping, and you may find your next breakthrough is just around the corner.

—