Did you know that aluminum is one of the most abundant metals in the Earth’s crust, making up about 8% of its weight? For the automotive industry, its lightweight properties mean it is quickly becoming the go-to material for manufacturers looking to improve fuel efficiency and reduce emissions. However, the transition from traditional heavy materials to aluminum components is not without its challenges. This is where CNC (Computer Numerical Control) aluminum machining comes in, a technology that has revolutionized manufacturing processes in various industries, particularly automotive.

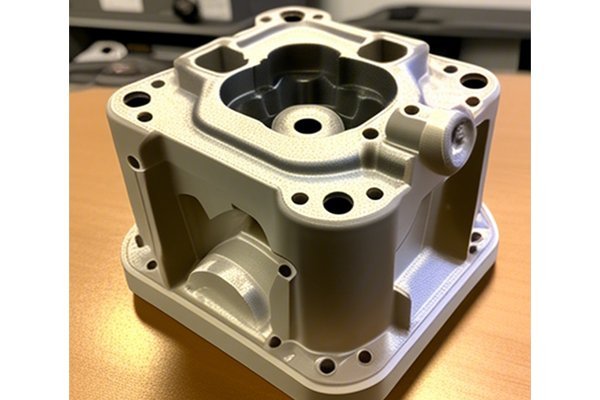

CNC aluminum machining involves the use of computerized control systems to operate machinery that cuts, shapes, and fabricates aluminum components to specified dimensions. The precision and flexibility of CNC machining have transformed it into a pivotal tool in the automotive industry, where products must meet rigorous safety and performance standards.

The automotive industry has many reasons for choosing aluminum over traditional materials like steel, including:

3.

The culmination of producing high-quality aluminum components begins with a well-thought-out design. Engineers utilize CAD (Computer-Aided Design) software to create detailed digital models of the intended products.

3.

Once the design is finalized, engineers generate G-code, which is a programming language that instructs the CNC machine on how to move and operate. This involves defining cutting paths, speeds, and feed rates necessary for accurate machining.

3.

During the machining phase, the CNC machine begins the actual fabrication process. Depending on the complexity of the part, multiple processes like milling, turning, and drilling may be employed. The machine operates with high precision to eliminate human error and ensure consistent quality.

3.

After initial machining, parts may require additional finishing techniques such as polishing, anodizing, or coating to improve aesthetics and durability.

4.

One of the most significant advantages of CNC machining is the exceptional accuracy it offers. Automotive components often require tight tolerances, and CNC machines can create complex parts with precision as tight as ±0.001 inches. This level of accuracy results in better fitting components, leading to improved vehicle performance and safety.

4.

CNC aluminum machining reduces human labor and minimizes errors in the manufacturing process. Automated controls allow for faster production cycles, meaning automotive companies can produce parts more quickly without compromising on quality. This speed is crucial in a fast-paced industry that demands rapid turnaround times.

4.

The flexibility of CNC machining allows automotive designers to innovate without significant constraints. Designers can create intricate geometries and features that would be challenging or impossible to achieve with traditional manufacturing techniques. This opens up new avenues for vehicle design and performance enhancements.

4.

While the initial setup for CNC machining may be outsized in terms of investment, the long-term cost savings outweigh these concerns. The reduced labor costs, minimized waste material, and shorter lead times contribute to a lower overall production cost. CNC machining is particularly cost-effective when producing large part volumes.

4.

CNC machinery is built to replicate the same operation with pinpoint accuracy. This consistency is vital for automotive manufacturers, especially when producing thousands of parts where each piece must meet identical specifications. Any variation can lead to significant quality control issues.

CNC aluminum machining is widely used in producing various automotive components, including:

While CNC aluminum machining offers many advantages, it also comes with challenges that automotive manufacturers must address, such as:

6.

Aluminum machining can lead to rapid tool wear due to the material’s softness. Choosing the right cutting tool material and implementing proper machining parameters can mitigate this issue.

6.

Achieving the desired surface finishing can be challenging. Selecting industry-best practices and advanced coating techniques plays a crucial role in maintaining high-quality surface finishes.

6.

Different aluminum alloys may exhibit unexpected behavior during machining. Proper material selection based on the specific application will minimize these risks and enhance overall production quality.

As technology evolves, the future of CNC aluminum machining in the automotive industry appears promising. Innovations such as:

In conclusion, CNC aluminum machining is an indispensable tool in the automotive industry’s quest for lighter, more fuel-efficient, and high-performing vehicles. Its unparalleled precision, efficiency, and ability to produce complex designs make it a preferred choice for manufacturers globally. As the industry continues to evolve with technological advancements, the importance of CNC aluminum machining will only grow.

By investing time and resources into understanding and implementing CNC aluminum machining, automotive manufacturers can remain competitive and pave the way for a cleaner, more efficient future in transportation. This technology is not just an option; it is essential in shaping the future of automotive engineering. Understanding these benefits and applications can be pivotal for organizations aiming for long-term sustainability and competitiveness in a challenging market.