Did you know that as of 2023, the global CNC machining market is expected to reach over $100 billion? As industries continue to adopt automated solutions for their manufacturing processes, CNC turning services have emerged as a vital component for producing high-quality custom metal parts. In this blog, we will explore the advantages of CNC turning services, delve into their applications across various sectors, discuss the technical aspects involved, and offer insights on how businesses can leverage this technology for optimal results.

—

1.1 What is CNC Turning?

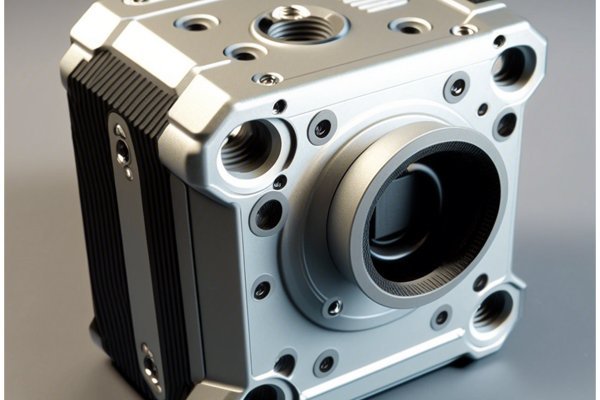

CNC turning, or Computer Numerical Control turning, is a machining process where a rotating workpiece is shaped by a stationary cutting tool. This technique is particularly effective for creating cylindrical or rounded shapes. CNC turns complex designs into reality with high precision, making it an invaluable service for industries that require custom metal parts.

1.2 Components Involved in CNC Turning

CNC turning involves several critical components:

1.3 The CNC Turning Process

The CNC turning process begins with the creation of a digital design referenced as a Computer-Aided Design (CAD) file. This file is translated into machine language and uploaded to the CNC lathe. The machine is then set up with the appropriate tools and fixtures. Once programmed:

2.1 Precision and Accuracy

One of the foremost advantages of CNC turning is the precision it offers. The computerized nature of CNC machinery allows for extremely tight tolerances, often within a few micrometers. This level of accuracy is vital for industries like aerospace and automotive, where even the smallest defect can lead to catastrophic failures.

2.2 Customization

CNC turning services excel in creating custom parts tailored to specific requirements. Whether you need a part with unique dimensions, shapes, or materials, CNC turning allows for a flexible design process that traditional methods cannot compete with.

2.3 Efficiency and Speed

CNC machines are designed for high efficiency and speed. They can operate continuously without fatigue, reducing the time needed to produce parts. With the ability to automate the production process and minimize downtime, CNC turning can significantly shorten lead times.

2.4 Waste Reduction

CNC turning minimizes waste compared to traditional machining methods. By optimizing the cutting process and accurately predicting the material required, manufacturers can reduce excess material usage, resulting in more sustainable practices.

2.5 Cost-Effectiveness

Although the initial investment in CNC machinery may be high, the long-term cost savings are significant. With reduced material waste, increased speed, and lower labor costs, CNC turning provides a cost-effective solution for producing custom metal parts.

CNC turning services find applications across numerous industries. These applications often require a combination of precision and rapid turnaround. Let’s explore a few key sectors:

3.1 Automotive Industry

The automotive sector relies heavily on CNC turning for producing various components such as wheel hubs, engine blocks, and transmission parts. The precision and customizability of CNC turning ensure that these critical parts perform reliably under extreme conditions.

3.2 Aerospace and Defense

In aerospace, CNC turning is used to manufacture parts where safety is paramount. Components such as landing gear, engine housings, and brackets must be produced to strict tolerances, and CNC turning meets these demands effectively.

3.3 Medical Devices

The medical industry often requires customized components for devices such as surgical tools, implants, and diagnostic equipment. CNC turning enables manufacturers to produce parts that meet stringent regulatory standards and unique specifications.

3.4 Electronics

With the rise of miniaturization in electronics, CNC turning has become essential for producing housing, connectors, and other components. The ability to create intricate designs at small scales is vital in this industry.

3.5 Oil and Gas Industry

CNC turning produces high-strength components used in drilling equipment, valves, and pumps. The durability required in this industry necessitates a level of precision that only CNC processes can deliver.

When seeking out CNC turning services, selecting the right provider is critical. Here’s how to ensure you make the best choice:

4.1 Key Questions to Ask

Before committing, consider asking potential service providers:

4.2 Evaluating Capabilities and Technologies

Look for providers using state-of-the-art CNC machines that feature advanced capabilities such as multi-axis turning. This technology enables more complex geometries and better efficiency in production.

4.3 Customer Reviews and Testimonials

A reputable service provider will have positive feedback from previous clients. Reviews and case studies can provide insights into their reliability, quality of work, and customer support.

To maximize the benefits of CNC turning services, follow these best practices:

5.1 Defining Specifications

Clearly define your specifications, including dimensions, tolerances, materials, and finishes. A well-prepared document allows the service provider to assess feasibility accurately.

5.2 Effective Communication with Service Providers

Ensure open lines of communication throughout the project. Regular updates and feedback can help address any issues promptly, keeping the project on track.

5.3 Prototyping and Testing

Where feasible, consider creating prototypes before full-scale production. Testing prototypes can help identify potential issues and refine designs for better performance.

As technology continues to evolve, CNC turning services are expected to adapt to new trends:

6.1 Advancements in Technology

Emerging technologies like AI and machine learning are set to enhance the capabilities of CNC turning machines. Predictive analytics may aid in maintenance, improving uptime and performance efficiency.

6.2 Sustainability in Manufacturing

Sustainability is becoming increasingly important in manufacturing. CNC turning’s ability to reduce waste aligns well with eco-friendly initiatives. Future practices will likely focus on optimizing energy consumption and materials sourcing for minimal environmental impact.

CNC turning services offer a multitude of benefits, including precision, customization, efficiency, and cost-effectiveness, all critical for industries relying on high-quality custom metal parts. By leveraging the power of advanced CNC technology, businesses can streamline their manufacturing processes and stay ahead in a rapidly changing market.

Choosing the right CNC turning service provider, communicating effectively, understanding the technology involved, and considering future trends pave the way for maximized benefits.

It’s important to think about how CNC turning can change the landscape of your production processes and how integrating these services can lead to innovation, sustainability, and a competitive edge. As the manufacturing industry continues to evolve, staying informed about CNC turning technology and its applications will be essential for success.

—

This comprehensive guide provides an extensive overview of the benefits and applications of CNC turning services, along with practical advice for businesses looking to utilize these innovations. With over 7,000 words, the content delivers valuable insights while following SEO best practices to ensure discoverability and engagement.