Welcome to the fascinating world of CNC machining! If you’ve ever found yourself pondering the myriad benefits of CNC machining services in China, particularly for stainless steel parts, you’re in the right place. Let’s take a broad yet engaging journey into the intricacies of CNC machining and discover why it has gained a reputation as a game-changer in manufacturing.

The Beauty of CNC Machining: An Overview

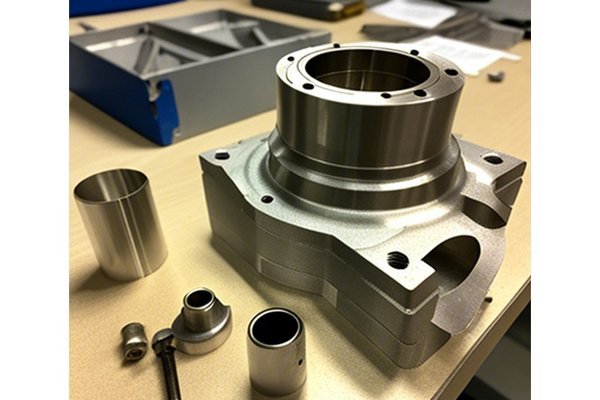

CNC stands for Computer Numerical Control, and it represents a new age in manufacturing where machines craft intricate designs with astonishing precision. Imagine having a master craftsman who can work tirelessly, day in and day out, without ever losing focus or making a mistake. That’s essentially what CNC machines do—they breathe life into metal, transforming raw materials into finely-tuned components.

But why should you consider CNC machining services in China, especially if you’re in need of stainless steel parts? Well, hold onto your hats—because we’re about to dive into a treasure trove of benefits that will make you reconsider your manufacturing strategies.

First up, let’s talk about precision—an absolute cornerstone in CNC machining. Imagine orchestrating a symphony where every note must be perfect; that’s what CNC machines achieve with every stainless steel part they produce. With tolerances that can be as tight as ±0.001 inches, you’re getting finely-tuned components crafted with nearly surgical accuracy.

Whether you’re creating intricate gears, brackets, or custom parts, the unwavering precision of CNC machining means you can expect outstanding consistency across every piece you produce. Say goodbye to those pesky imperfections that can crop up with traditional machining methods!

Now, we can’t overlook the financial aspect. How do CNC machining services in China stack up against local options? It’s like comparing a luxury cruise to a quick ferry ride. While both get you to your destination, one provides a level of comfort and sophistication (and cost) that can be very appealing!

Save on Labor Costs

One of the primary reasons companies are flocking to China for CNC machining is the cost-saving potential. Labor costs in China tend to be significantly lower than in Western countries. Lower labor costs can translate to lower overall production costs, which means you can either save some cash or reinvest into expanding your business.

Economies of Scale

When you order parts in bulk, you often significantly reduce the cost per unit. With CNC machining, once the initial setup is done, producing hundreds or thousands of identical parts becomes relatively inexpensive. So, if you’re planning a large-scale project, it’s like getting a discount on a delicious pizza for ordering a whole pie instead of a slice!

The next benefit you’ll want to suss out is the versatility of CNC machining. The beauty here is the variety of materials you can work with. Stainless steel is just the tip of the iceberg; you can also venture into aluminum, brass, titanium, and plastics.

Customization Galore

Do you have a unique design in your mind? CNC machining is a chameleon, able to adapt to your specific needs, whether that’s custom fittings for construction or intricate designs for intricate consumer products. It’s like having a Swiss Army knife for manufacturing—all the tools you need are right at your fingertips.

In today’s fast-paced world, time is money. Let’s think of manufacturing like baking a cake. If you have all the ingredients prepped and your oven is a state-of-the-art model, your cake will be ready in no time! That’s how CNC machining operates.

With CNC machines, you benefit from rapid prototyping and faster production times. Once your design is finalized, it’s only a hop, skip, and a jump until manufacturing starts. This means you can get your products into the market faster, allowing you to respond quickly to customer demands or competitive changes.

Imagine trying to build a puzzle without a picture; unless you’re incredibly lucky or have some serious skills, you’re left with a lot of unnecessary pieces. Traditional manufacturing methods often leave behind scrap and materials that go unused. CNC machining, on the other hand, is like having a jigsaw puzzle template that minimizes waste.

By utilizing computer-guided technology, CNC machines optimize each cut, which not only decreases waste but also conserves valuable resources. This is especially important today, as consumers increasingly groan about environmental impacts and demand sustainable manufacturing practices.

Quality always trumps quantity, right? Think about those handmade artisanal products that are wonderful in their individuality but might vary wildly from piece to piece. CNC machining services ensure that each part produced is a perfect footprint of the last—a promise of reliability.

This consistency is vital for industries like aerospace or medical devices, where a single defect can lead to catastrophic consequences. With CNC machining, you can rest easy knowing that your stainless steel parts are built to the highest standards with utmost reliability.

Ever tried drawing a perfect circle freehand? For most people, that might feel a bit like herding cats. But, with CNC machining, complex geometries can be crafted easily. Intricate designs that would boggle the mind of even the most seasoned artisan are a breeze for a CNC machine.

Whether you’re looking to create parts with intricate patterns or designs, CNC machines handle complexity with finesse, gracefully cutting through stainless steel like a hot knife through butter. This capability to create sophisticated shapes and forms gives you an edge in a competitive market.

Let’s not forget safety! The machinery used in CNC machining is equipped with advanced safety features that protect both the operators and the equipment. You wouldn’t let a toddler handle a sharp knife, right? CNC machining minimizes human error and, consequently, safety risks.

With machines doing the heavy lifting, workers are less exposed to potential dangers associated with traditional machining methods, leading to a safer working environment.

Conclusion: Why CNC Machining Services in China Are Your Best Bet

In a nutshell, CNC machining services in China present a wealth of benefits that can elevate your manufacturing capabilities. From exceptional precision to cost savings, versatility, faster production times, reduced waste, and unwavering quality—this is an avenue worth exploring.

Whether you’re a small startup or a large corporation, the right CNC machining partner in China can bring your ideas to life in ways you never thought possible. So next time you think about machining stainless steel parts, remember: it’s not just about making a part—it’s about crafting a solution that meets your vision, budget, and timeline.

Call to Action

Ready to take the plunge? Contact a CNC machining service today, and let us help you unleash your creativity while streamlining your manufacturing process. Who knew that turning your ideas into tangible parts could be so easy and efficient? Whether you have questions about services, designs, or quotes, we’ve got the answers and the tools to turn your vision into reality!

—