Did you know that copper has been used by humans for more than 10,000 years? Its exceptional conductivity, malleability, and resistance to corrosion make it an essential material across various applications, from electrical wiring to plumbing systems. As industries evolve, the demand for precision machined copper components continues to grow. This is where CNC (Computer Numerical Control) turning comes into play, revolutionizing the way we produce intricate copper parts. In this comprehensive guide, we will explore the multifaceted benefits of CNC turning for copper precision machining, delving into techniques, industry applications, and the value it brings to modern manufacturing.

Understanding CNC Turning

What Is CNC Turning?

CNC turning is a manufacturing process that uses computer-controlled machines to shape materials into specific forms. It primarily involves rotating the workpiece against a stationary cutting tool, which removes material to create desired shapes and dimensions. This method is not limited to just copper, but it shines when producing high-tolerance components from this unique metal.

The Importance of Precision

In today’s competitive market, precision is non-negotiable. The need for exact dimensions, tolerances, and repeatability is paramount in the manufacturing sector. CNC turning allows manufacturers to produce copper components with notable accuracy, which is vital for applications in the aerospace, automotive, and electronics industries.

The Benefits of CNC Turning for Copper Precision Machining

One of the most significant benefits of CNC turning is the ability to create highly accurate and precise components. CNC machines have a closed-loop control system that continuously monitors the positioning of the tool, allowing for tight tolerances with minimal deviation.

This level of precision is crucial in fields such as electronics, where the slightest deviation from the desired specifications can lead to malfunctioning devices or inefficiencies.

CNC turning is remarkably efficient compared to traditional machining methods. Once programmed, CNC machines can operate continuously without the need for rest breaks, leading to shorter production times.

While the initial investment in CNC equipment can be substantial, the long-term cost benefits often outweigh these start-up costs. Increased efficiency means shorter lead times and reduced labor costs, making CNC turning a financially sound choice for manufacturers.

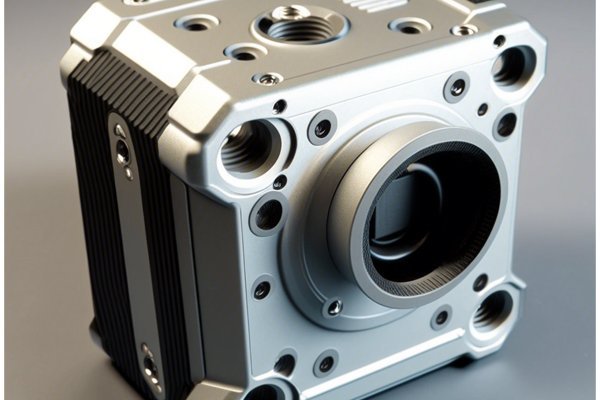

Copper components often require intricate designs with complex geometries. CNC turning excels in producing complicated shapes that would be labor-intensive and cost-prohibitive to achieve manually.

The flexibility of CNC turning machines allows manufacturers to quickly adapt to changing demands. Whether it’s a minor adjustment in design or a complete shift in production volume, CNC technology offers versatility.

CNC turning machines are equipped with sophisticated monitoring and control systems that ensure quality throughout the production process. Automated quality checks can highlight any deviations from specifications in real-time.

CNC turning can be adapted to work with various copper alloys, allowing manufacturers to select the best material for a specific application. Whether it’s C11000, C26000, or other copper alloys, CNC machines can deliver consistent results tailored to the material properties.

CNC Turning Techniques in Depth

Effective CNC turning necessitates the right choice of cutting tools. Factors such as:

Optimizing the CNC turning process involves:

The integration of robotics and automation systems with CNC turning machines further enhances efficiency and accuracy. Automated material handling and quality checks can significantly reduce production downtime.

Applications of CNC Turning in Various Industries

The aerospace sector often requires copper components in electrical wiring and connectors, where high precision is critical. CNC turning’s ability to produce lightweight yet strong components makes it an ideal choice.

In the automotive field, CNC-turned copper parts are vital for electrical systems, sensors, and battery connectors. With the rise of electric vehicles, the demand for such components is set to grow.

The electronics industry relies heavily on copper due to its excellent conductivity. Components such as circuit boards, connectors, and heat sinks often require the precision available through CNC turning.

Medical devices frequently utilize copper for its antimicrobial properties and excellent conductivity. Precision machining is crucial in this industry, where reliability and safety are above all.

In summary, CNC turning for copper precision machining brings numerous benefits that streamline manufacturing processes while ensuring quality and accuracy. From enhanced speed to intricate designs and cost-effectiveness, CNC technology has redefined how we produce copper components.

As industries continue to evolve, the importance of precision manufacturing cannot be overstated. CNC turning is not just a viable option; it is quickly becoming the standard for quality and efficiency in the production of copper components.

Remember, whether you’re in aerospace, automotive, or electronics, understanding the advantages of CNC turning can significantly impact your production capabilities. Embrace the power of technology to stay competitive and responsive to market demands. The future of manufacturing is here, and it’s time to rethink how you approach copper precision machining!