Did you know that aluminum is the second most abundant metal in the Earth’s crust, making up about 8% of it? It’s lightweight, corrosion-resistant, and highly malleable, which explains why it has become a preferred material across various industries. As industries continue to innovate and evolve, the demand for custom aluminum alloy parts—precision-engineered to meet specific requirements—has surged. This is where CNC (Computer Numerical Control) machining comes into play, revolutionizing manufacturing processes.

In this extensive blog post, we will delve into the intricacies of CNC machining for custom aluminum alloy parts. We will explore its applications, benefits, typical processes, and the factors to consider when choosing a CNC machining service. Through this exploration, you’ll gain a comprehensive understanding of how CNC machining can solve challenges encountered in manufacturing custom aluminum components.

The Rise of CNC Machining

CNC machining involves automated processes that utilize computer software to control machine tools. This technology has replaced manual processes in manufacturing, facilitating faster production with greater accuracy.

Historical Context

Originally developed in the 1940s, CNC machining has evolved dramatically over the decades. Today, advanced CNC systems can create components with no manual input other than programming, raising production efficiency to new heights.

Why Aluminum?

The choice of aluminum alloy for custom parts can be attributed to its properties including:

Understanding Custom Aluminum Alloys

When referring to custom aluminum parts, understanding the differences among aluminum alloys is crucial. There are numerous types of aluminum alloys, generally categorized into two groups: wrought and cast.

Wrought Aluminum Alloys

Wrought alloys are shaped through processes like rolling and extrusion. They offer superior mechanical properties and are typically used for structural applications.

Cast Aluminum Alloys

Cast alloys are created from molten aluminum that is poured into a mold. They offer better fluidity and detail precision, making them ideal for intricate designs.

Popular Aluminum Alloys in CNC Machining

Some of the common aluminum alloys used in machining include:

The CNC Machining Process

CNC machining for custom aluminum parts follows a systematic process that involves several key steps:

The initial step is creating a detailed design using CAD (Computer-Aided Design) software. Designers can create intricate models and share them with engineers for review.

Choosing the right aluminum alloy is vital based on the requirements of the final product. Factors to consider include anticipated load, environmental conditions, and aesthetic needs.

Once the design is approved, CNC programmers develop a set of instructions—known as G-code—that communicates with the CNC machine. This code dictates the movement and function of the machine tools.

The CNC machines use cutting tools to carve the aluminum into the desired shape based on the programmed instructions. Various techniques can be employed, including:

After machining, numerous finishing processes can enhance the component’s properties and aesthetics, including:

Before final delivery, each component undergoes rigorous quality checks. Advanced measurement tools assess dimensions, tolerances, and surface finish, ensuring compliance with industry standards.

The Benefits of CNC Machining for Custom Aluminum Parts

The advantages of utilizing CNC machining for custom aluminum parts are numerous and impactful:

CNC machining allows for highly detailed designs with tolerances that can reach within microns. This level of precision ensures that components fit seamlessly in their intended applications.

CNC machines can operate continuously, minimizing downtime. This capability is particularly favorable for businesses requiring mass production, as CNC machining can significantly reduce manufacturing time while maintaining quality.

Whether it’s a single prototype or a large production run, CNC machining enables businesses to tailor components to specific sizes, shapes, and material properties based on individual needs.

CNC machining can handle a variety of materials—aluminum alloys, plastics, metals, and more. This versatility opens up avenues for applications across diverse industries, including aerospace, automotive, medical, and consumer products.

The automated precision of CNC machines means that less material is wasted during production. This assists companies in minimizing their raw material costs and is also aligned with sustainable practices.

CNC machines reduce the need for manual labor in hazardous cutting and milling processes, improving safety on the factory floor.

Applications Across Industries

CNC machining for custom aluminum parts has a broad range of applications:

Custom aluminum components are fundamental in aircraft and spacecraft. The lightweight nature of aluminum alloys contributes to fuel efficiency, and CNC machining enhances the precision needed for aerodynamics.

In automotive manufacturing, CNC machined aluminum parts help reduce vehicle weight, improve fuel efficiency, and enhance performance. Components like engine blocks, brackets, and chassis parts are often made from aluminum.

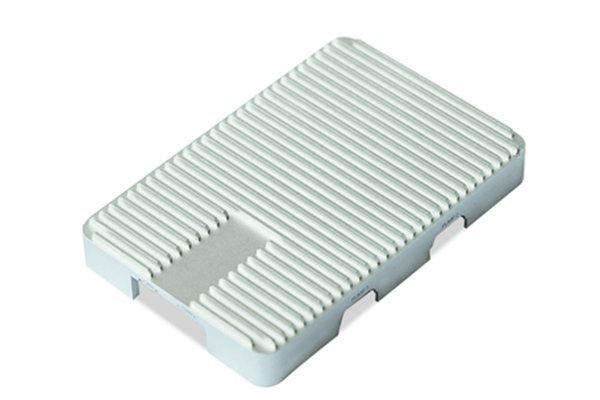

CNC machining produces heat sinks, brackets, and enclosures in electronics, where aluminum’s thermal properties play a crucial role in managing heat and ensuring device longevity.

The precision of CNC machining is vital in producing components for medical devices. Custom aluminum parts can ensure the integrity and reliability needed in health care applications.

From appliances to sporting goods, custom aluminum parts enhance the durability and functionality of everyday consumer products.

Key Considerations When Choosing a CNC Machining Service

CNC machining for custom aluminum alloy parts presents a powerful solution for various industries looking for precision-engineered components. With its myriad benefits—including enhanced precision, efficiency, and versatility—CNC machining not only addresses manufacturing challenges but also propels industries into the future.

As you consider CNC machining for your aluminum components, remember the importance of choosing a reputable service provider that aligns with your specific needs. The right partner can elevate your projects, ensuring high-quality, durable parts that contribute significantly to your overall production.

Understanding the nuances of this manufacturing process and the advantages it holds is crucial for anyone involved in product development and engineering. The world of CNC machining continually evolves, combining technology and creativity to produce the parts of tomorrow.

Investing in CNC machining for custom aluminum alloy parts is not just about modern manufacturing; it’s about future-proofing your business in an increasingly competitive landscape.