Did you know that nearly 90% of manufacturers now use some form of computer numerical control (CNC) technology in their prototyping processes? As industries evolve, the demand for intricate, high-quality prototypes continues to rise. This is where CNC milling emerges as a game-changing solution—especially in its ability to efficiently produce complex geometries that are often impossible with traditional machining methods.

In the realm of manufacturing and prototyping, complexity is king. The more intricate a design can be, the more unique and innovative the resulting product can be. However, crafting such complex geometries poses significant challenges for engineers and manufacturers. This is where CNC milling, with its unparalleled precision and versatility, offers a path not only to overcome these challenges but also to enhance product development cycles.

This blog will dive deep into CNC milling techniques specifically for complex geometry prototyping. We’ll explore what CNC milling is, its advantages, the intricacies involved in milling complex shapes, and a plethora of applications across various industries. Buckle up for a comprehensive journey that will equip you with the knowledge and strategies necessary to efficiently navigate the complexities of modern prototyping.

What is CNC Milling?

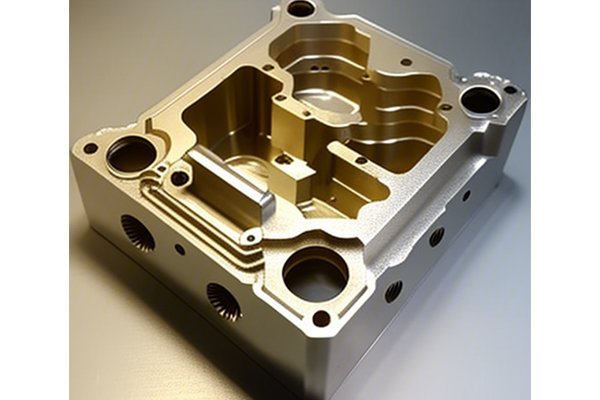

CNC milling is a subtractive manufacturing process where computer-controlled machines are used to remove material from a workpiece to shape it into the desired form. It involves various cutting tools that rotate at high speeds to carve out material with extreme accuracy. The term “CNC” stands for “Computer Numerical Control,” which means that the milling machine is controlled by a computer program that directs the movement of the cutting tools along multiple axes.

Key Components of CNC Milling

Why CNC Milling Matters for Complex Geometry

The intricacy of modern design demands a prototyping method that can consistently deliver high precision while handling complex shapes. Here are some key advantages of utilizing CNC milling for complex geometries:

Detailed Solutions for CNC Milling Complex Geometries

While the benefits of CNC milling for complex geometry prototyping are evident, successfully navigating this process requires understanding several factors and methodologies.

The process starts with powerful CAD software that allows engineers to create precise designs. Once the design is finalized, CAM software translates this into machine code.

An effective tool path strategy is essential when milling complex shapes. This involves determining the most efficient route that the cutting tool will take during the machining process.

Choosing the right material is crucial for achieving the desired properties in the prototype. Different materials respond differently to milling processes.

Selecting the right tools is vital for executing complex designs without compromising quality.

Different techniques can be employed in the CNC milling process tailored for complex geometries.

The surface finish of milled parts can significantly affect performance and aesthetics.

Applications of CNC Milling in Various Industries

CNC milling is integral to numerous industries, each benefiting from the ability to prototype complex geometries efficiently:

The Future of CNC Milling

As technology advances, the capabilities of CNC milling continue to expand. Innovations such as AI-driven CNC machines, automated setups, and improved material processing techniques promise to revolutionize the industry further.

CNC milling has undeniably transformed the landscape of complex geometry prototyping. Through advanced CAD and CAM software, innovative toolpath strategies, and a strong emphasis on material choices, manufacturers can produce high-quality, precise prototypes that meet market demands.

In this blog, we have explored the essential components of CNC milling, strategies for overcoming common challenges, the various applications across industries, and a glimpse into the future of this exciting technology. As companies continue to innovate and push boundaries, understanding and utilizing CNC milling will be crucial for remaining competitive.

So, whether you’re a seasoned manufacturer or a newcomer to the prototyping scene, pondering how to integrate CNC milling into your processes is more important than ever. As the foundation of the next generation of design and manufacturing, CNC milling is not just a tool—it’s a bridge to the future of industry innovation.