Why CNC Machining Customization is a Game-Changer

Have you ever struggled to find a manufacturing solution that balances precision, speed, and cost-effectiveness? If so, you’re not alone. Many businesses face challenges like delayed delivery times, quality control issues, and skyrocketing costs when working with traditional machining methods.

As someone deeply involved in the CNC machining industry, I’ve seen how customization can revolutionize production processes. In this article, I’ll share the top five reasons why opting for CNC machining customization could be the perfect solution for your business. Whether you’re in aerospace, automotive, electronics, or another sector, these insights will help you make an informed decision.

1. Unmatched Precision: The Backbone of Quality Manufacturing

When it comes to precision, CNC machining stands in a league of its own. Customization elevates this capability, ensuring your parts meet exact specifications every time.

a. Why Precision Matters

Imagine producing medical equipment or aerospace components with even the slightest deviation from the design. It’s not just about functionality—it’s about safety, compliance, and reputation. CNC machining’s ability to deliver high-tolerance parts consistently is invaluable.

b. How Customization Enhances Precision

Customization allows for tailored toolpaths and specialized fixtures, enabling parts to achieve tighter tolerances than standard machining. At YL-Machining, we use advanced CAD/CAM software to create bespoke machining strategies that ensure optimal precision for every project.

c. Real-World Example

Recently, we worked with a client in the robotics industry who required parts with a tolerance of ±0.001 inches. By leveraging CNC customization, we exceeded their expectations, resulting in improved performance and reliability for their final product.

2. Shorter Lead Times: Delivering Projects Faster

Time is money, especially in manufacturing. Custom CNC machining significantly reduces production time, allowing you to meet tight deadlines without sacrificing quality.

a. Streamlined Workflow

Unlike conventional methods that require multiple setups and manual interventions, CNC machines operate with minimal downtime. Customization further speeds up the process by optimizing machining sequences specifically for your project.

b. Prototyping Made Easy

Need a prototype fast? Custom CNC machining enables rapid prototyping by automating complex operations and reducing the need for additional finishing processes. This is particularly beneficial for startups or R&D teams looking to test designs quickly.

c. Meeting Market Demands

A recent project at YL-Machining involved producing custom aluminum enclosures for an electronics manufacturer. Thanks to our streamlined CNC processes, we reduced their delivery timeline by 30%, helping them stay ahead of market demand.

3. Cost-Effective Manufacturing: Maximizing Your Budget

Contrary to popular belief, CNC machining customization isn’t just for high-budget projects. In fact, it can save costs in several key areas:

a. Material Optimization

With tailored machining strategies, material waste is significantly reduced. Customization ensures that every cut is purposeful, minimizing scrap and lowering material expenses.

b. Reduced Labor Costs

Automation plays a huge role here. CNC machines handle intricate tasks without the need for constant human oversight, which translates to fewer labor hours and reduced operational costs.

c. Long-Term Savings

While the initial investment in CNC customization might seem higher, the long-term savings from improved efficiency, reduced waste, and fewer errors more than compensate for it.

Real-Life Impact

For a recent aerospace client, we implemented a custom CNC solution that cut their production costs by 25%. This not only boosted their profitability but also allowed them to invest in other growth areas.

4. Versatility in Materials and Applications

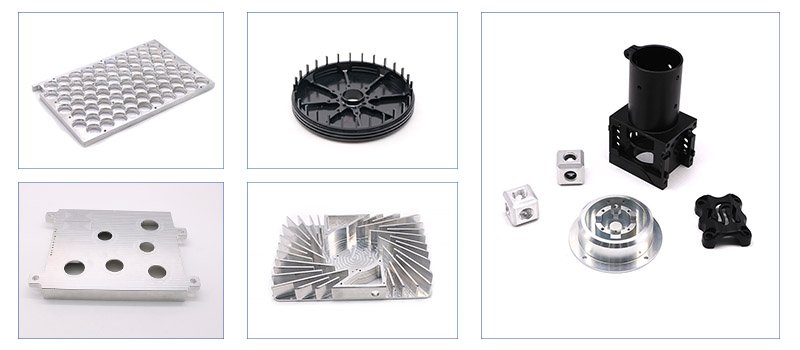

CNC machining is versatile, but customization takes it to the next level by allowing for intricate designs across a wide range of materials.

a. Material Diversity

From titanium and brass to plastics and composites, CNC customization handles them all. Each material has unique characteristics, and a customized approach ensures the best results. For example:

- Titanium: Ideal for aerospace but requires cooling strategies to prevent tool wear.

- Brass: Excellent for electronics, with customization ensuring precise cuts.

- Aluminum: Lightweight yet durable, perfect for automotive applications.

b. Application-Specific Solutions

Custom CNC machining allows for specialized features like undercuts, complex geometries, and surface treatments tailored to specific industry requirements.

c. Example Use Case

A client in the medical field needed stainless steel surgical tools with ergonomic designs and polished finishes. Our customized CNC process delivered parts that met strict medical standards while maintaining a flawless aesthetic.

5. Improved Quality Control and Post-Sale Support

One of the biggest pain points in manufacturing is inconsistent quality. Custom CNC machining addresses this with rigorous quality control measures tailored to your project’s needs.

a. Built-In Quality Assurance

Customization allows for the integration of real-time monitoring systems that detect and correct errors during production. This proactive approach ensures parts meet exact standards before they leave the machine.

b. Post-Sale Reliability

At YL-Machining, we believe that our relationship with clients doesn’t end with delivery. Our customized solutions come with dedicated post-sale support to address any concerns or adjustments needed.

c. Enhancing Customer Satisfaction

A recent partnership with an automotive supplier demonstrated how our customized approach improved their product’s reliability, leading to a 15% increase in customer satisfaction ratings.

Conclusion: Custom CNC Machining is the Future of Manufacturing

Precision, speed, cost efficiency, versatility, and quality control—these are the pillars of modern manufacturing. By choosing custom CNC machining, you’re not just solving immediate production challenges; you’re investing in a sustainable and scalable solution for the future.

At YL-Machining, we specialize in delivering tailored CNC solutions that help businesses thrive. Whether you need rapid prototyping, high-precision parts, or cost-effective production, we’ve got you covered.

Ready to elevate your manufacturing process? Contact YL-Machining today and let’s discuss how custom CNC machining can transform your business.