3000 series aluminum alloys are widely used in the industrial field for their balanced physical properties and high cost performance. These alloys have manganese as the main alloying element and have medium strength, good machinability and excellent corrosion resistance. This article will introduce the CNC machining technology, characteristics, application cases and future trends of 3000 series aluminum alloys in detail.

Characteristics of 3000 series aluminum alloys

Medium strength: Although the strength of 3000 series aluminum alloys is not as good as that of 2000 series or 7000 series, they have a good balance between strength and flexibility and can be easily formed and bent without breaking.

Corrosion resistance: These alloys have excellent corrosion resistance, especially in marine and industrial environments, and are suitable for applications exposed to moisture or chemicals.

Machinability and formability: 3000 series aluminum alloys are extremely machinable and can be easily made into various shapes, making them ideal materials for making complex parts.

Non-heat-treatable properties: 3000 series aluminum alloys cannot be strengthened by heat treatment. They can be strengthened by cold machining, which is to deform the material mechanically to improve its properties.

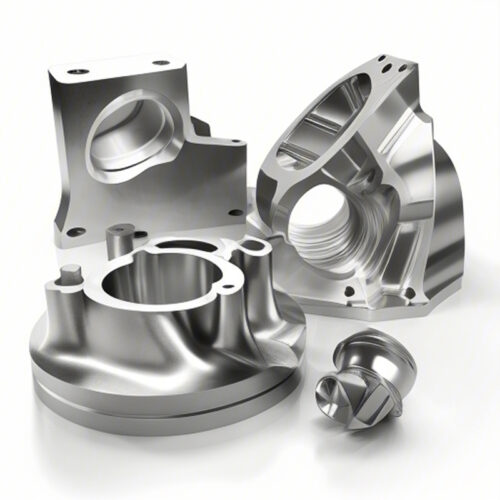

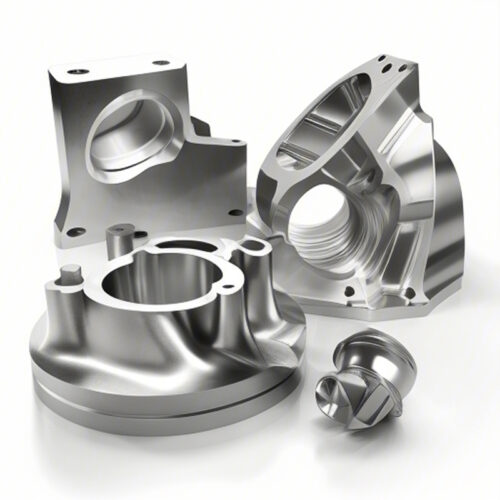

CNC machining technology

CNC machining is a high-precision mechanical machining technology suitable for producing parts with complex shapes and high precision requirements. For CNC machining of 3000 series aluminum alloys, the main processes include:

Milling: used to make flat surfaces, grooves and complex shapes.

Turning: used to make circular or symmetrical parts.

Drilling: used to make precise holes.

Application cases

Automotive industry: 3000 series aluminum alloys are used in heat exchangers, body panels and fuel tanks in the automotive industry. Their corrosion resistance and lightweight properties help improve fuel efficiency and durability.

Electronic industry: In the electronics industry, these alloys are used for housings and radiators. These industries require good thermal conductivity and corrosion resistance.

Food and beverage packaging: 3000 series aluminum is widely used in the packaging industry, especially beverage cans and food containers. These alloys are non-toxic, corrosion-resistant and easy to form.

Construction: In the construction sector, 3000 series aluminum is used for roofing, siding, and insulation, which can withstand environmental factors and is easy to install.

Challenges and Solutions in Machining

Cutting Forces: Although the cutting forces of 3000 series aluminum alloys are relatively low, the appropriate cutting tool and parameter selection is still crucial.

Cutting Heat: The heat generated during machining is high, and effective cooling measures are required.

Chip Control: Due to the ductility of the material, long chips are easily generated, requiring the use of chipbreaker tools or adjustment of cutting parameters.

Future Trends

New Material Development: With the advancement of materials science, the development of new 3000 series aluminum alloys will provide higher strength and corrosion resistance.

Advanced Manufacturing Technology: The emergence of technologies such as 3D printing has opened up new avenues for the application of 3000 series aluminum alloys.

Sustainable Development: Future 3000 series aluminum alloys will pay more attention to sustainability and reduce environmental impact by optimizing composition and manufacturing processes.

3000 series aluminum alloys have become ideal materials for CNC machining due to their excellent physical and chemical properties. As technology continues to develop, the application of 3000 series aluminum alloys will continue to expand, bringing more innovation and value to the manufacturing industry.