Did you know that in the aerospace industry, a single faulty component can lead to catastrophic failures, not just in terms of financial loss but also human lives? Statistics from the Federal Aviation Administration (FAA) reveal that about 80% of all aircraft accidents are due to mechanical failures. This stark reality underscores the critical importance of precision manufacturing in aerospace prototyping. Given the high stakes involved, how can manufacturers ensure that components are made with the utmost precision? One of the most promising technologies today is Computer Numerical Control (CNC) milling. This blog delves into the suitability of CNC milling for high-precision aerospace prototyping, exploring its advantages, limitations, and best practices, and providing insights into ensuring the success of aerospace projects.

Understanding CNC Milling

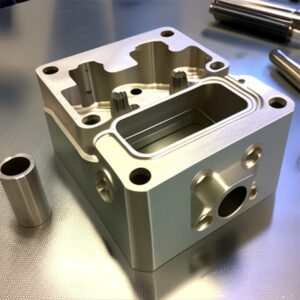

CNC milling is a subtractive manufacturing process that utilizes computer-controlled machines to remove material from a workpiece. These machines, programmed with precise specifications, can execute complex designs and cuts at high speeds and with remarkable accuracy. The technology enables manufacturers to create intricate prototypes and components using various materials, a critical requirement in the aerospace sector.

How CNC Milling Works

CNC milling machines operate through a series of steps:

Key Advantages of CNC Milling in Aerospace Prototyping

Limitations of CNC Milling for Aerospace Prototyping

While CNC milling offers numerous advantages, it also comes with several limitations:

Comparing CNC Milling to Other Machining Methods

When considering CNC milling for aerospace prototyping, it’s essential to compare it to other machining methods:

Best Practices for Implementing CNC Milling in Aerospace Prototyping

To maximize the benefits of CNC milling in the aerospace sector, consider the following best practices:

Case Studies: Successful Applications of CNC Milling in Aerospace Prototyping

Case Study 1: Boeing’s Use of CNC Milling for the 787 Dreamliner

Boeing has extensively employed CNC milling technology in the manufacturing of the 787 Dreamliner. The company utilized advanced CNC machines to create precise engine components and wing structures, significantly reducing lead times and material waste. By integrating DFM principles, Boeing managed to streamline operations and ensure high-quality parts that align with strict aviation standards.

Case Study 2: Lockheed Martin’s CNC Machining Process for the F-35 Lightning II

Lockheed Martin leverages CNC milling for the production of complex components in the F-35 Lightning II aircraft, such as structural components and thermal shields. With a focus on quality and consistency, the company has established a robust quality assurance program to maintain precision manufacturing throughout the machining process, ensuring each component meets military specifications.

Case Study 3: Airbus and Custom CNC Solutions

Airbus has adopted customized CNC milling solutions to manufacture critical components for their aircraft. By collaborating with CNC manufacturers to design tailored tooling and machining processes, Airbus has achieved exceptional precision in producing landing gear and fuselage sections. This case emphasizes the importance of partnerships in advancing CNC milling capabilities in aerospace.

Future Trends in CNC Milling for Aerospace

As technology continues to evolve, several trends are expected to shape the future of CNC milling in the aerospace industry:

In the world of aerospace prototyping, precision, reliability, and efficiency are of paramount importance. CNC milling emerges as a cutting-edge solution compatible with these critical requirements, offering manufacturers the ability to produce high-quality components that meet strict industry standards. By understanding its advantages, addressing its limitations, and implementing best practices, aerospace companies can effectively leverage CNC milling technology in their prototyping processes.

As we explored through various case studies, industry giants like Boeing and Lockheed Martin have reaped the benefits of CNC milling in crafting advanced aerospace components. Looking ahead, trends in AI, sustainability, and hybrid manufacturing suggest a promising future for CNC milling in the aerospace sector.

In conclusion, prioritizing CNC milling for aerospace prototyping is not only a strategic move but a necessary requirement in an industry where precision can mean the difference between success and failure. As technology advances, staying informed about these developments will be critical in maintaining a competitive edge in aerospace manufacturing. Therefore, manufacturers should take the time to assess their CNC milling capabilities and consider adopting this technology if they haven’t already. In an industry defined by precision, CNC milling is a noteworthy tool that can significantly influence design and production outcomes.

Related Posts

- Here’s a suggested FAQ title based on the provided keywords: What are the Key Technical Points for Ensuring Surface Polishing in CNC Machining?

- How to Stress Relieve Parts After CNC Machining for Improved Performance?

- How Does Aluminum Extrusion Machining Improve Efficiency in Manufacturing Processes?

-300x225.jpg)

-300x225.jpg)