: An Intriguing Fact About Brass

Did you know that brass, a centuries-old alloy of copper and zinc, has been in use since 500 BC? Brass is renowned for its durability, versatility, and aesthetic appeal. In the world of manufacturing, brass plays an integral role, especially in CNC machining—a process that transforms raw materials into finely crafted parts for various industries. Among brass alloys, 517 brass stands out for its unique properties. How does it fare when it comes to CNC machining? Is it suitable for intricate designs, precise tolerances, and the demands of modern manufacturing? In this blog, we will delve into the characteristics of 517 brass, its advantages, its challenges in CNC machining, and why it might be an ideal choice for your next project.

Understanding 517 Brass: Composition and Characteristics

What is 517 Brass?

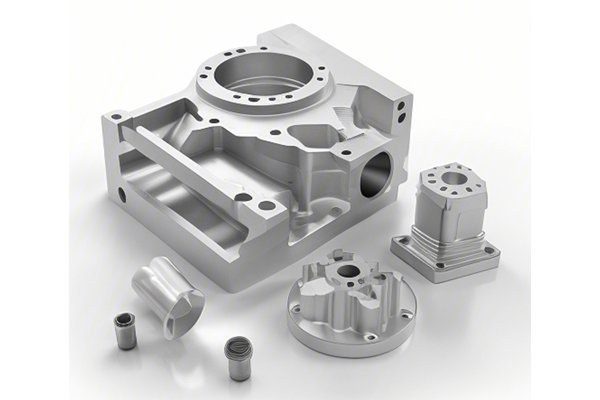

517 brass, also known as leaded brass, typically consists of copper (around 59%), zinc (about 39%), and a small percentage of lead (around 2%). The addition of lead enhances its machinability, making it one of the preferred materials in CNC machining. Its favorable properties have made it a popular choice in applications requiring complex shapes and superior finish, including fittings, valves, and other mechanical components.

Key Characteristics

Common Applications of 517 Brass

Due to its unique properties, 517 brass is widely used in various industries, including:

The CNC Machining Process

What is CNC Machining?

Computer Numerical Control (CNC) machining refers to a manufacturing process where pre-programmed computer software controls the movement of production equipment. This process allows for the automated control of machinery, including lathes, mills, routers, and grinders, to produce precise and complex parts.

How CNC Machining Works

Advantages of Machining 517 Brass on CNC Machines

CNC machining allows for exceptional precision, which is crucial when working with 517 brass for complex parts. The ability to automate cuts leads to improved accuracy and repeatability, minimizing human error.

While the initial setup for CNC machining can be substantial, it often proves to be cost-effective in the long run. The rapid production capabilities and reduced labor costs associated with CNC machining mean that manufacturers can produce high volumes of parts quickly.

CNC machines are capable of executing an array of tasks—from drilling and milling to turning and laser cutting—making them a versatile tool for producing 517 brass parts.

One of the most significant advantages of CNC machining is its ability to create intricate designs that would be challenging, if not impossible, to achieve through traditional machining methods. This is especially important for applications in aerospace or medical devices, where high complexity and tight tolerances are required.

CNC machining improves material utilization, minimizing waste. When using 517 brass, a material known for its cost and value, this efficiency translates to significant cost savings.

Challenges of Machining 517 Brass

While 517 brass offers numerous benefits, it also presents certain challenges in CNC machining that manufacturers need to consider.

Even though 517 brass is machinable, the cutting tools can experience significant wear, particularly during high-speed operations. This necessitates the use of more robust materials for cutting tools, which can increase costs.

Effective chip management is essential during machining. The presence of lead in 517 brass can facilitate chip formation, but improper chip control can result in tool damage or degraded part quality.

Finding the right balance between machining speed and tool life is vital. While faster speeds might seem appealing, they could lead to excessive wear or poor part finish if not properly managed.

Achieving a fine surface finish on CNC machined parts can be challenging with 517 brass. Special attention must be given to cutting parameters and tool selection to ensure the desired finish is achieved.

Techniques to Optimize CNC Machining of 517 Brass

To overcome the challenges of machining 517 brass and maximize its benefits, manufacturers can adopt several strategies:

Choosing the right cutting tools is essential. High-speed steel (HSS) or carbide tools are often recommended for machining brass. Coated tools can also enhance performance and reduce wear.

Establishing ideal cutting speeds, feed rates, and depth of cut significantly affects the machining process. Conducting tests to identify optimal settings for tooling and machine variables can yield the best results.

Utilizing appropriate coolant and lubrication techniques is critical for reducing friction, preventing overheating, and extending tool life during CNC machining.

Implementing chip management systems, such as blow-off systems or chip conveyors, ensures that chips are effectively removed from the cutting area, leading to improved visibility and reducing the risk of tool damage.

Utilizing high-precision CNC machines with excellent rigidity and stability reduces errors and ensures higher-quality parts.

: The Significance of Understanding 517 Brass in CNC Machining

In conclusion, 517 brass is a highly suitable material for CNC machining, presenting a wealth of benefits—from enhanced machinability and precision to versatility across various applications. While challenges such as tool wear and surface finish quality exist, applying the right strategies, including optimal tool selection and effective chip management, can significantly improve machining performance.

By understanding the fundamental properties of 517 brass and the implications of CNC machining, manufacturers can make informed decisions, optimize production processes, and enhance product quality. As industries increasingly demand higher precision and complex components, the significance of CNC machining with alloys like 517 brass cannot be overstated.

In the competitive landscape of modern manufacturing, staying ahead requires not just knowledge but a willingness to explore the nuances of materials and methodologies. Understanding how 517 brass interacts with CNC machining opens up possibilities for innovation and efficiency. Thus, manufacturers should not only consider 517 brass for its immediate advantages but also its long-term potential in their machining processes. Remember, the right material and the right process lead to superior products—a principle worth thinking about in your next project.