Did you know that up to 30% of a CNC machining operation’s overall cycle time can be wasted due to improper workpiece clamping and positioning? This statistic underscores just how crucial these two aspects are in the realm of CNC machining—especially when it comes to achieving unparalleled accuracy and efficiency. In this extensive blog, we will explore the multifaceted strategies you can implement to optimize workpiece clamping and positioning, ultimately elevating your machining operations.

—

Understanding the Basics of Workpiece Clamping and Positioning

What is CNC Machining?

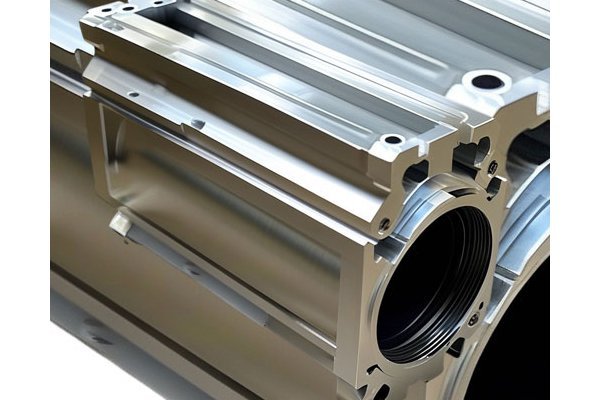

CNC (Computer Numerical Control) machining refers to the automated process of converting a computer design into precise mechanical workpieces. It involves the use of various types of machining tools controlled by computer software to remove material from a solid block. However, for CNC machining to yield high-quality results, it is essential to have a solid understanding of workpiece clamping and positioning.

Importance of Proper Clamping and Positioning

When a workpiece is improperly clamped or positioned, it can lead to various issues such as:

—

Key Techniques for Optimizing Workpiece Clamping

The first step toward effective clamping is selecting the right type of vise for your machining tasks. You have various options, including:

When choosing a vise, it is essential to consider the shape, size, and material of the workpiece you will be machining. A misaligned or incompatible vise can jeopardize accuracy.

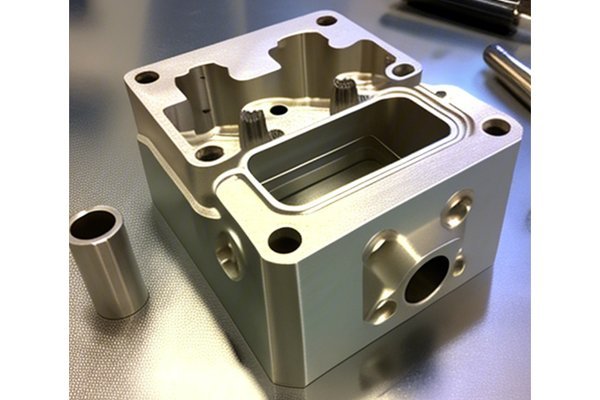

Fixture plates can enhance accessibility and efficiency in your CNC setup. By using standardized holes and patterns, they allow for quick adjustments and easy repositioning of workpieces. You’ll find many types of fixture plates that can cater to different workpiece sizes and shapes.

Different clamping devices serve varied purposes:

Investing in high-quality clamping devices will ensure consistent performance and reliability, minimizing potential errors during machining.

Knowing when to employ secure or soft clamps will significantly impact your clamping strategy. Secure clamps are best for hard, rigid materials, while soft clamps are recommended for softer materials that could deform under excessive pressure.

—

Precision Positioning Methods

Implementing a CMS allows for the accurate measurement of workpiece dimensions during the setup phase. CMS will help you verify that components are secured in their designated positions before machining begins.

Employing alignment techniques such as:

Taking the time to properly align your workpieces will significantly reduce the likelihood of errors.

Marking tools like layout dyes and scribe tools can assist in accurately marking where cuts and drills need to occur. This direct approach gives operators a clear indication of where the machining should be applied.

Custom jigs and fixtures tailored to specific parts can drastically improve positioning accuracy. These tools are designed to hold workpieces in a fixed location, ensuring they do not move during the machining process.

—

Strategies for Enhanced Workpiece Stability

Tools that have high rigidity will resist deflection during machining. Consider investing in solid carbide tools or high-speed steel tools that can effectively minimize vibrations, reducing the risk of workpiece shifting.

Older machines often lack the precision required for reliable clamping and positioning. Upgrading your machine tool will not only improve accuracy but also allow for advanced software that simplifies setup and monitoring processes.

Machine performance can be severely affected by environmental variables like temperature and humidity. Ensure your machining environment is climate-controlled to mitigate deformation risks and maintain the integrity of your parts.

—

Best Practices for Monitoring Workpiece Position and Clamping

Incorporate sensors and monitoring technology that provide real-time feedback on workpiece stability and clamping force. This allows for immediate corrections if misalignment or movement occurs.

Consistent inspections of clamping devices and fixtures can help catch wear and tear before escalating issues arise. Regular calibration and adjustments will prolong the lifespan of your tools and improve precision.

Investing in comprehensive training programs for operators will ensure they understand the importance of proper clamping and positioning techniques. Skilled workers can often spot issues before they become problematic.

—

Optimizing workpiece clamping and positioning in CNC machining is not merely a technical requirement but a critical factor that significantly influences the accuracy, quality, and efficiency of your operations. By implementing the techniques and best practices outlined in this blog—ranging from selecting appropriate clamping devices to continuous monitoring and maintenance—you can considerably enhance your machining processes.

Ensuring the integrity of your workpiece setup isn’t just about avoiding errors; it’s about creating a workflow that supports longevity and consistency in production. In a competitive landscape, businesses that invest in mastering these fundamentals will keep any competitive edge.

Remember, the importance of precision in CNC machining cannot be overstated. As the industry continues to evolve, understanding and applying optimized clamping and positioning techniques will only grow more vital. Your commitment to accuracy today shapes the quality of your output tomorrow. Prioritize these core concepts, and you will pave the way for successful, precise machining operations.