In a world where DIY culture flourishes, the demand for precision, customization, and efficiency in manufacturing processes has never been higher. Whether you’re creating intricate models, custom electronics, or unique mechanical components, the ability to produce high-quality parts that fit specification and style is paramount. This is where YL Machining steps into the spotlight, redefining possibilities through customized CNC machining.

CNC (Computer Numerical Control) machining has been a game-changer in the manufacturing landscape, enabling users to create complex parts with a level of precision that was previously unattainable. This article delves into the intricate world of customized CNC machining, exploring its advantages, the technology behind it, and how it can revolutionize your DIY projects. Together, we’ll explore best practices, potential challenges, and the future of CNC machining.

Understanding CNC Machining

What is CNC Machining?

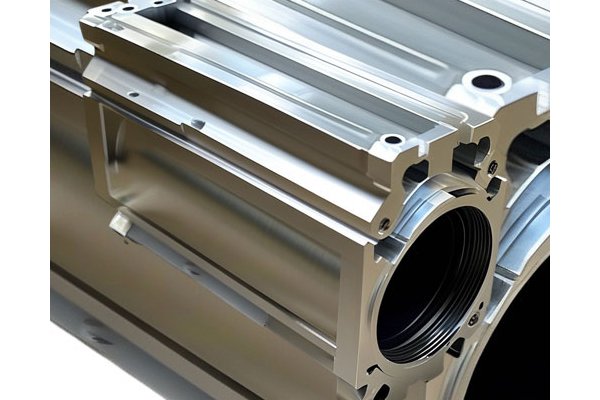

CNC machining is a subtractive manufacturing process that employs computer-controlled tools to shape and cut materials into the desired forms. Unlike traditional machining approaches that might rely on manual controls, CNC machining utilizes coded instructions and automated tooling to ensure superior accuracy and repeatability.

Key Components of CNC Machining:

The Process of CNC Machining

Benefits of CNC Machining in DIY Projects

For DIY enthusiasts, custom CNC machining opens a treasure trove of possibilities. Here are some benefits:

Why YL Machining for Your DIY Needs?

At YL Machining, our commitment runs deep; we seek to combine cutting-edge technology with a passion for creativity and innovation. Our experienced team offers personalized consultation and expert guidance through every step of the machining process, ensuring that you get tailored solutions that meet your exact requirements.

Customizing Your CNC Machining Projects

How to Choose the Right Material

Designing for CNC Machining

Selecting the Right CNC Machining Service

Application of Customized CNC Machining in Various Industries

Aerospace Industry

Within the aerospace sector, where precision and reliability are non-negotiable, customized CNC machining plays an essential role. Engine components, brackets, and housings require not only precision but must also adhere to stringent safety standards. The ability to fabricate lightweight yet durable parts using advanced materials sets CNC machining as a staple in aircraft production.

Automotive Industry

Customized CNC machining is vital for creating components that meet the unique demands of the automotive industry. From one-off restorations to mass-production parts, CNC machines can adapt quickly to evolving designs, ensuring improved performance. Whether it’s custom brackets for car modifications or gear assemblies for performance vehicles, the flexibility of CNC machining is unparalleled.

Medical Industry

In the medical realm, the customization capabilities offered by CNC machining can lead to improved patient outcomes. Medical implants, surgical instruments, and diagnostic equipment must not only meet specific dimensions but often individualized designs tailored to the patient’s needs. CNC machine precision allows for the development of complex shapes and features essential in this field.

Consumer Electronics

CNC machining extends its benefits to the consumer electronics industry, where unique housing designs and functional components are the norms. From phone cases to intricate circuit boards, precision machining offers durability, aesthetic appeal, and the flexibility to create designs that stand out in a crowded market.

Overcoming Challenges in Customized CNC Machining

Understanding Tolerances and Fit

The tolerance levels in CNC machining can be a double-edged sword. While high precision is alluring, a poor understanding of tolerances can lead to fitment issues. Always communicate clearly about tolerances with your CNC provider.

Tool Wear and Maintenance

CNC machining tools can wear down over time, affecting precision and quality. Regular maintenance schedules and tool replacement are essential to ensure consistent performance. YL Machining employs comprehensive quality control measures to monitor tool condition and performance continually.

Cost Management

Costs associated with CNC machining can quickly spiral out of control if not managed properly. Design choices, machining processes, and material selections all impact the overall cost. YL Machining adheres to transparent pricing and is committed to providing value without comprising quality.

Future of Customized CNC Machining

As technology evolves, CNC machining is set to become even more integrated into the DIY creative process. Advancements in AI and machine learning will help refine machining processes, making it easier than ever for hobbyists and professionals to create bespoke parts quickly and efficiently.

Additionally, as sustainability becomes a priority across industries, CNC machining offers significant advantages through material efficiency and waste reduction practices. Enhanced software will further contribute to minimizing energy consumption, moving toward environmentally friendly manufacturing.

At YL Machining, we believe that the spirit of DIY deserves a strong foundation of precise and reliable production capabilities. Customized CNC machining offers not only the precision and efficiency needed for creative projects but also opens up a world of possibilities for innovation.

So whether you’re a hobbyist looking to bring your idea to life or a professional aiming to streamline production, leverage our knowledge and expertise at YL Machining. Let us be part of your journey toward realizing your imaginative projects while enjoying the elegance and accuracy that customized CNC machining provides.

Through understanding, collaboration, and precision, there’s no limit to what you can achieve. We invite you to connect with us today, explore our services, and witness first-hand how customized CNC machining can transform your creations and aspirations into reality.

—