Imagine you’re a craftsman, meticulously shaping your vision into reality. You have your design locked in, but there’s a barrier: the cost of turning it into a tangible product. That’s where CNC machining swoops in like a superhero. But what if I told you that getting high-quality CNC machining services doesn’t have to break the bank? Let’s delve into this intricate world of CNC machining and explore how to strategically navigate your options while ensuring quality doesn’t take a back seat.

Understanding CNC Machining: A Brief Overview

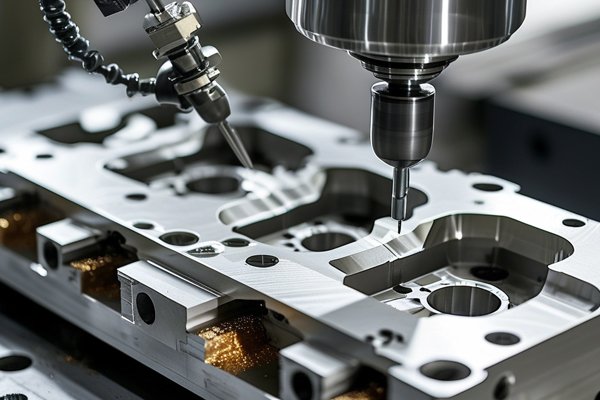

Before we start pinching pennies, let’s make sure we’re all on the same page about what CNC machining actually is. CNC stands for Computer Numerical Control, a technology that uses computers to control machine tools. This means that your designs, no matter how complex, can be translated into precise movements, ensuring that every cut, bend, and shape is accurate to the point of error being nearly non-existent.

Think of it as a digital sculptor—it takes your ideas and chisels them into existence with precision that the human hand might struggle to replicate.

Why CNC Machining Can Be Expensive

You might be scratching your head, thinking, “If CNC machining is so precise, why does it tend to be expensive?” The truth is, quality comes at a cost. Here are a few factors driving up those prices:

Finding Affordable CNC Machining Services: Tips and Tricks

So, how can you find those elusive, affordable options? Buckle up! Here are some tried-and-true methods to help you get the best bang for your buck without sacrificing quality.

Do Your Research

Just like you wouldn’t buy a car without seeing the price tags and reviews, you shouldn’t jump headfirst into CNC machining without a bit of digging.

Get Multiple Quotes

Why settle for one when you can compare? Requesting quotes from multiple machining services will offer you a comprehensive view of the market rates.

Consider Local vs. Overseas Options

A common misconception is that local services are always more expensive.

Utilize Online CNC Machining Platforms

In today’s digital world, the internet is a treasure trove of opportunities. Online CNC machining platforms like Xometry or Protolabs connect you with service providers, allowing for instant quotes and design uploads.

Evaluate the Importance of Design for Manufacturability (DFM)

For your designs to come to life affordably, they need to be DFM-friendly.

Maximize Production Runs

If you have the capacity to manufacture in bulk, do it!

Consider the Material Wisely

Choosing the right material is crucial—here’s where you can save some serious bucks without cutting corners on quality.

Forge Relationships with Suppliers

Building a good relationship with your CNC machining service can turn into golden opportunities.

Quality Control: Don’t Ignore It!

As we wrap up our money-saving journey, remember that just because you’re looking for affordability doesn’t mean you can skimp on quality.

Conclusion: Elevating Your CNC Machining Experience

Isn’t the world of CNC machining fascinating? With its interplay of technology, creativity, and precision, it’s a domain filled with endless possibilities. By implementing these strategies, you can unlock the gates to affordable CNC machining services without sacrificing the quality you desire.

By doing your research, obtaining quotes, using online platforms, and engaging with your suppliers, you can set yourself up for success in your projects. Remember, quality should never take a back seat, and every part you create is a testament to your craftsmanship.

Now, what are you waiting for? Get out there, explore your options, and let your ideas take shape without worrying about emptying your pockets! If you have any questions or need a bit more guidance, feel free to reach out—knowledge is meant to be shared, after all!