Did you know that a mere 0.1% variance in precision during CNC machining can lead to major issues in mass production? In high-stakes industries such as aerospace, automotive, and medical, inconsistencies in machined parts can result in product failures, compromised safety, and significant financial losses. Understanding how to maintain precision during CNC processing isn’t just an option—it’s a necessity.

In this blog post, we’ll delve deeply into the intricacies of CNC processing, explore the common challenges faced during mass production, and provide practical solutions for ensuring consistent precision. Whether you’re a seasoned machinist or a newcomer to the field, this comprehensive guide will equip you with the knowledge to enhance your operations.

Understanding CNC Machining

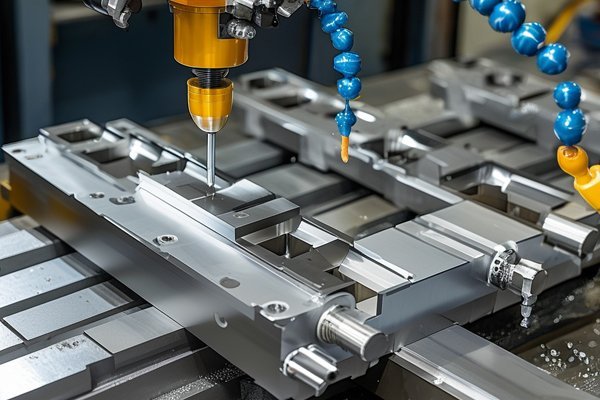

CNC, or Computer Numerical Control, machining refers to the automated control of machine tools using a computer. This technology has revolutionized the manufacturing landscape, enabling the production of intricate designs with remarkable accuracy. However, as mass production ramped up in various sectors, the focus on maintaining precision became paramount.

Importance of Precision in CNC Machining

Key Challenges in Achieving Precision

Though CNC technology is advanced, several factors can hinder precision:

Each of these challenges is a call to action for manufacturers aiming to enhance their precision in CNC machining.

Practical Solutions for Ensuring Consistent Precision

Achieving consistent precision requires a multifaceted approach. Below are actionable strategies to mitigate the challenges associated with CNC processing in mass production.

Establish a Scheduled Maintenance Program: Running regular maintenance on CNC machines can identify potential problems before they escalate.

Calibrate Machines Regularly: Ensure machines are calibrated in accordance with their specific operating standards. This can involve checking the backlash, squareness, and alignment.

Select the Right Tooling Materials: Using tools made from high-performance materials can enhance durability and therefore accuracy.

Monitor Tool Wear: Employ tool condition monitoring systems which can alert operators on wear, thus maintaining precision during production.

Analyze Cutting Speeds and Feeds: Adjusting speed and feed rates according to the material being machined can contribute to enhanced precision.

Implement Adaptive Machining: Use software to automatically adjust parameters based on real-time data during machining.

Utilize Coolants and Lubricants: Effective cooling can mitigate thermal expansion, ensuring that the material properties remain stable during processing.

Climate Control in Machining Environment: Maintain a controlled temperature in the production area to minimize the effects of environmental fluctuations.

Employ Multi-Axis Machining: Advanced CNC machines, such as those capable of multi-axis operations, can create complex parts without compromising precision.

Integrate CAD/CAM Systems: Using advanced CAD/CAM software can streamline the transition from design to production, reducing potential human error.

Implement Real-Time Monitoring: Systems that monitor factors like vibration and sound can identify issues before they affect precision.

Feedback Loops: Create a loop where operators can assess the finished products and calibrate or modify processes accordingly.

Ongoing Operator Training: Continuous training sessions can help machine operators stay updated on best practices, reducing human error.

Cross-Training Staff: Encourage workers to learn about different machines and processes, fostering a flexible workforce adept at maintaining precision.

Regular Inspection Protocols: Implementing strict quality assurance checks at regular intervals can help identify and resolve precision issues quickly.

Utilize Statistical Process Control (SPC): This data-driven method can help monitor production processes and identify variations in real time.

Align with Material Suppliers: Working closely with suppliers to ensure consistent quality in raw materials can significantly impact the machining process.

Feedback Loop with Production Teams: Establish regular communication regarding quality issues, allowing for swift resolution of any potential deviations.

In the fast-paced world of CNC machining, particularly in mass production, ensuring consistent precision is not merely beneficial; it is crucial. Factors such as tool wear, machine calibration, and material variability need to be managed to maintain high standards.

By implementing regular maintenance, investing in quality tools, optimizing machining parameters, and capitalizing on advanced technologies, manufacturers can overcome common challenges associated with CNC processing. Continuous training for staff and robust quality control measures further solidify operations.

The strategies discussed in this blog illustrate the complex interplay of various factors in the pursuit of precision. As manufacturers strive for excellence, proactive approaches are vital in minimizing discrepancies.

In today’s highly competitive market, companies that prioritize precision are not just going to fulfill orders—they are going to set themselves apart, ensuring client satisfaction and long-term success. Therefore, it’s important to reconsider the impact of precision in your production processes and strive for excellence—your bottom line depends on it.

Related Posts

- Can CNC machining effectively process parts with specific elastic deformation requirements?

- How does the relationship between machining hourly cost and equipment investment influence CNC machining selection?

- How does the price trend of CNC machining materials affect machining costs in the manufacturing industry?