Did you know that the feed rate in CNC machining can significantly impact not only the surface finish quality of your parts but also the efficiency of the machining process itself? In the world of CNC machining, particularly when working with materials like brass, mastering the intricacies of feed rate determination can be the key to elevating your production capabilities and ensuring consistency in finished components. In this blog post, we will delve into the factors influencing feed rate in CNC machining of brass and provide practical guidance on how to calculate the ideal feed rate for your specific applications.

Understanding Feed Rate in CNC Machining

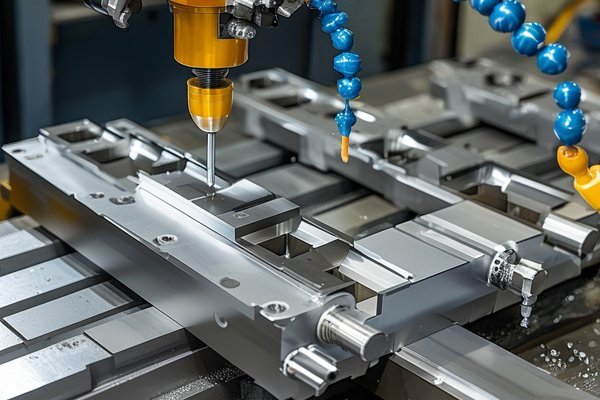

Feed rate refers to the speed at which the cutting tool advances into the material while machining. It is a crucial parameter that directly influences machining time, tool wear, surface finish, and part accuracy. In CNC machining, the feed rate is commonly expressed in units such as millimeters per minute (mm/min) or inches per minute (ipm).

When working with materials like brass, it’s essential to find a feed rate that balances cutting speed with tool life and surface quality. Notably, too high of a feed rate can lead to tool wear, poor surface finish, and even machine downtime due to broken tools. Conversely, too slow of a feed rate can result in idling machines and lowered production efficiency.

Factors Affecting Feed Rate in CNC Machining of Brass

Calculating the Ideal Feed Rate for Brass Machining

To effectively calculate the ideal feed rate for CNC machining brass, several steps can be followed:

The cutting speed for brass commonly varies between 25-150 m/min, depending on the tool material and operation type. For instance, carbide tools can handle higher cutting speeds due to their hardness.

The formula for calculating feed rate (F) is:

[ F = text{Vc} times frac{(1/1000)}{text{N}} ]

Where:

The spindle speed can also be calculated using the diameter of the tool (D) and desired cutting speed (Vc):

[ N = frac{Vc times 1000}{pi D} ]

Typically, a feed rate per tooth is selected based on tool diameter and material. For brass, a feed per tooth value can range from 0.05 mm to 0.15 mm, depending on the tool and the operation.

Once you implement your initial calculations, watch for signs of tool wear and surface finish quality. If your tools are wearing too quickly or if surface finish isn’t satisfactory, adjust your feed rate accordingly.

Monitoring and Optimizing the Feed Rate

After setting an initial feed rate, ongoing monitoring can identify further optimizations, including:

Understanding and determining the feed rate when CNC machining brass is crucial for achieving optimal performance and maintaining efficient production processes. By reviewing the material properties, incorporating calculations for cutting speed and spindle speed, and continually monitoring your results, you can refine your approach to feed rate management successfully. This attention to detail not only enhances the quality of your machined parts but also extends tool life, reduces costs, and improves production timelines.

Remember, getting the feed rate right for your CNC machining is not just about numbers but understanding the interaction of various parameters and striving for a balance to meet your production goals. This is why mastering feed rate determination is an essential aspect of any CNC machinist’s skill set—an investment that pays off not just for the present but for sustainable manufacturing success in the future.

In the ever-evolving world of CNC machining, the commitment to optimizing crucial factors like feed rates will ensure you remain competitive, innovative, and efficient. Take the time to assess your machining processes and embrace the precision that comes from informed decisions!