*

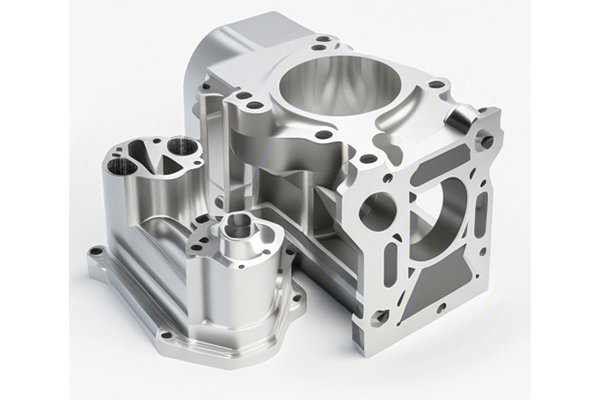

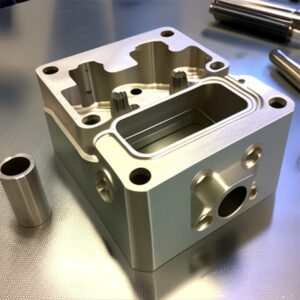

In the advanced manufacturing sector, Computer Numerical Control (CNC) machining has become a pivotal technology enabling precision and efficiency in part production. One of the critical decisions engineers and manufacturers face in this domain is selecting the suitable metal material for prototype machining. Given that prototype parts often undergo rigorous testing and usage, choosing a wear-resistant metal becomes vital for ensuring that the final product meets both functional and longevity requirements. In this blog post, we at YL Machining will explore the characteristics of various wear-resistant metals, how they compare, and provide insights on making the best choice for your CNC machining needs.

—

Understanding Wear Resistance

What Does Wear Resistance Mean?

Wear resistance refers to the ability of a material to withstand wear due to mechanical action such as friction, impact, and erosion. In CNC machining, wear can lead to premature component failure, increased maintenance costs, and potential safety hazards. Therefore, the wear resistance of the material chosen dictates how suitable it is for a particular application, especially when components will face considerable stress or friction during operation.

Key Types of Wear

Understanding these types of wear helps in specifying the right material properties needed, which can include improved hardness, toughness, chemical stability, and fatigue resistance.

Factors Influencing Material Selection

Different applications impose varying demands on wear resistance. For instance, components in the mining industry must withstand harsh conditions, while aerospace components must balance weight and strength. The following questions can guide your decision-making process:

When selecting a wear-resistant metal, it is crucial to evaluate its mechanical properties, including:

The chosen metal should be easy to machinable and fit within your production capabilities. Considerations should include:

Budget constraints are a reality in manufacturing. The chosen material’s cost must fit within the overall project budget while providing sufficient performance. Conducting a cost-benefit analysis can be beneficial by examining alternatives’ initial costs versus their lifespans and failure rates.

—

Evaluating Popular Wear-Resistant Metals

In CNC machining, various metals stand out for their wear-resistant properties. Here’s a closer look at some of the most commonly utilized metals.

Hardened steel is one of the most widely used materials for wear resistance due to its excellent hardness and strength.

Stainless steel offers a great balance between wear resistance and corrosion resistance.

Tool steels are engineered for performance and durability, making them suitable for high-wear applications.

Titanium alloys are known for their high strength-to-weight ratio and excellent corrosion resistance.

While not as hard as steel, certain aluminum alloys offer decent wear resistance and light weight.

In some cases, applying a wear-resistant coating, such as tungsten carbide or chrome plating, can enhance the performance of less durable metals significantly.

on Material Selection

Choosing the right wear-resistant metal material for CNC prototype machining requires a thorough understanding of application requirements, mechanical properties, and budget constraints. Each metal has unique characteristics, making it suitable for various applications, and a meticulous evaluation ensures that the selected material aligns with specific goals.

—

Making the Decision: Best Practices

Assessing various metals against application criteria allows for informed decisions based on empirical data rather than assumptions. Use detailed material property charts and benchmarks to guide your selection.

Engaging with material scientists or suppliers can provide insights that are crucial when selecting the right alloy and can help you understand any new developments in wear-resistant materials that may better suit your needs.

Always perform a cost-benefit analysis to weigh immediate and long-term costs. Consider the potential savings from reduced maintenance and part failures when investing a bit more upfront.

If possible, create prototypes with different materials to assess performance under real-world conditions. This practical approach will lead to the discovery of potential issues that theoretical assessments may not unveil.

—

In CNC machining, the right material selection is paramount when creating wear-resistant prototypes. At YL Machining, we understand the complexities involved and are committed to delivering high-quality machining services tailored to your needs. By evaluating all factors from application requirements to mechanical properties and budget, you position yourself and your business for success. The manufacturing landscape is continuously evolving, and we’re here to ensure your ventures remain ahead of the curve. Whether you need consultation or prototyping solutions, YL Machining stands ready to assist.

For further information, please feel free to contact us or visit our website to learn more about our CNC machining capabilities and how we can support your projects.

-300x225.jpg)

-300x225.jpg)