Introduction

In the modern manufacturing landscape, choosing the right CNC parts manufacturer is a crucial step for any business relying on precise machining and high-quality components. With a plethora of options available, companies often find themselves confused about selecting the ideal partner that not only meets their specifications but also aligns with their vision, quality standards, and budget constraints. This article aims to provide a comprehensive guide to assist you in navigating this essential decision-making process.

—

Understanding CNC Machining

What is CNC Machining?

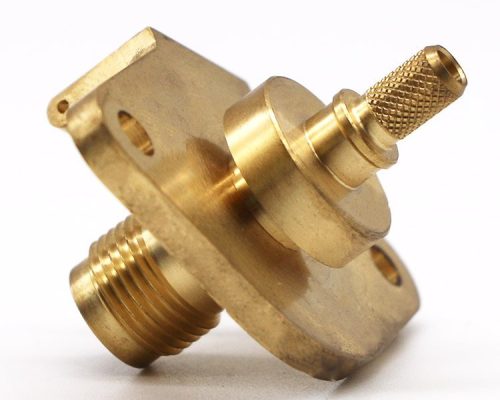

CNC (Computer Numerical Control) machining is a method that utilizes computers to control machine tools. This process allows for the precise fabrication of parts from various materials, including metals and plastics. The CNC machining services range from milling and turning to laser cutting, all of which aid in producing custom CNC parts with accuracy.

Importance of CNC Machining Parts

Quality CNC machining parts are fundamental to the integrity and functionality of the final products. Components made using CNC technology boast tolerances often within a few thousandths of an inch, which is critical in industries ranging from aerospace to automotive manufacturing.

—

Identifying Your Specific Needs

Define Your Project Requirements

Before beginning your search for a CNC parts manufacturer, take time to clearly outline your project requirements. Consider the following facets:

Budget Constraints

Understanding your budget is essential when selecting a CNC machining service. While it may be tempting to choose the least expensive option, compromise on quality could lead to higher costs down the line due to rejections and failures.

—

Researching Potential Manufacturers

Online Reviews and Ratings

Leverage online platforms to scrutinize potential CNC parts manufacturers. Websites like Trustpilot, Google Reviews, and specialized engineering forums are valuable resources for unfiltered insights from previous clients.

Industry Expertise

Evaluate the manufacturer’s expertise in your specific industry. Different industries, such as automotive, aerospace, and medical, may require specialized knowledge and experience in machining services.

Certifications and Compliance

Select manufacturers that uphold industry standards and possess relevant certifications such as ISO

—

Assessing Capabilities

Range of CNC Services Offered

Investigate the range of CNC services provided by potential manufacturers. A versatile company offering everything from custom CNC machining services to CNC machining quotes can better accommodate your evolving business needs.

Technology and Equipment

The type of machinery and technology used by a CNC parts manufacturer significantly impacts quality and precision. Ensure the manufacturer employs state-of-the-art equipment that aligns with the complexity of your projects.

Prototyping and Custom Machining

The ability to produce prototypes can greatly impact your project, especially when custom machining is required. Manufacturers that can quickly generate prototypes enable you to test and refine designs, reducing time-to-market.

—

Quality Assurance Measures

Inspection and Testing Procedures

Inquire about the manufacturer’s quality assurance measures. Robust inspection and testing protocols, such as CMM (Coordinate Measuring Machine) inspections, should be standard practices to ensure the precision and reliability of your CNC parts.

Material Traceability

Ensure that the manufacturer maintains traceability of materials used in production. This is especially important in industries requiring strict compliance and regulation.

—

Communication and Customer Service

Responsiveness

Effective communication is vital to ensuring a smooth workflow. Observe how promptly potential manufacturers respond to inquiries, as this is often indicative of their overall service commitment.

Collaboration

A good manufacturer should be open to collaboration and flexible enough to adapt to design changes or project scope adjustments.

—

Evaluating Costs

Quoting Process

Request detailed quotes from multiple manufacturers. Analyze the breakdown of costs, including material, labor, and operational overheads to ensure you are making an informed comparison.

Hidden Costs

Be cautious of hidden costs that may arise during production. Ask about any additional fees for processes such as tooling, setup, or last-minute changes.

—

Making the Final Decision

Comparing Manufacturers

Once you have gathered sufficient information, compare your shortlisted manufacturers on various criteria including quality, production capability, reliability, and customer service.

Visit Facilities

If possible, visit the manufacturing facilities to gain first-hand insight into their operations, quality control measures, and overall environment.

—

Conclusion

Choosing the right CNC parts manufacturer is a multifaceted process that involves careful consideration of various elements ranging from specific project needs to the manufacturer’s capabilities. By following the guidelines outlined in this article, you can navigate the complex landscape of CNC machining with confidence. Ultimately, selecting a partner who truly understands your needs and offers high-quality custom CNC machining services will pave the way for successful project outcomes and a fruitful manufacturing journey.

—

References

—