When it comes to creating custom parts for robots, precision, quality, and efficiency are non-negotiable. As someone who has worked extensively in the CNC machining industry, I understand the importance of choosing the right CNC machining shop for your robot parts. The process of selecting the right manufacturing partner is critical to the success of your project—whether you’re designing parts for industrial robots, medical robots, or even personal assistants like drones. Today, I want to share with you my insights on how to choose a CNC machining shop that can deliver high-quality, custom robot parts with the accuracy and timeliness that the robotics industry demands.

Why CNC Machining is Crucial for Robot Parts

Before diving into the selection process, let’s quickly revisit why CNC machining is such an essential part of the robotics manufacturing landscape. CNC machining—which stands for Computer Numerical Control machining—is a manufacturing process that uses computers to control machine tools, allowing for the production of highly precise and complex parts.

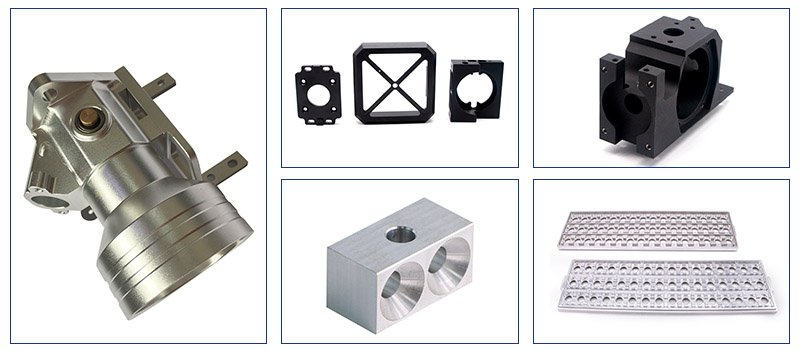

When it comes to robot parts CNC machining, the process ensures that the components are made with the utmost accuracy, which is absolutely necessary for robots to function effectively. From joints and actuators to sensors and casings, robots require custom parts that are tailored to fit exact specifications. CNC machining is ideal for producing these components because of its ability to work with tight tolerances, a variety of materials, and complex geometries—all critical features when building high-performance robots.

So, if you’re working on a robotics project and need custom parts, selecting the right CNC machining shop is the first and most important step. Let’s explore what to look for in a CNC machining shop to ensure you’re getting the best parts for your robots.

1. Experience and Specialization in Robotics

When choosing a CNC machining shop, the first thing you should look for is experience, particularly in the robotics industry. It’s essential that the shop has a proven track record of producing robot parts CNC machining because this guarantees they understand the unique requirements of the field. Robotics requires parts that can withstand stress, wear, and movement—whether it’s a robot arm, a gripper, or an actuator. A shop experienced in robotics will be familiar with these challenges and know how to address them.

If possible, check the shop’s portfolio to see examples of their work with robotic parts. Do they have experience with similar components to what you’re designing? Can they show you successful case studies? A specialized CNC shop will have a range of complex and precision parts in their portfolio that you can evaluate.

2. Quality Control and Precision

When working with robot parts CNC machining, precision is everything. Even the slightest deviation in measurements can result in a malfunctioning robot, leading to costly delays or failures in the system. The machining shop you choose should prioritize quality control, ensuring that every part meets the exact specifications you require.

Here are a few things to check when evaluating a shop’s quality control process:

- Tolerances: Does the shop specialize in working with tight tolerances? CNC machining is known for its precision, and a good shop should be able to produce parts within a thousandth of an inch or even tighter.

- Inspection Procedures: How do they inspect their parts? A reliable CNC machining shop will have robust in-house inspection processes, such as using coordinate measuring machines (CMMs) to check the accuracy of parts before they are shipped.

- Certifications: Does the shop have industry-standard certifications, such as ISO 9001 for quality management? This certification indicates that the shop has the processes in place to ensure consistently high-quality parts.

3. Material Selection and Capabilities

Robotic parts often require materials with specific properties, whether it’s strength, lightness, heat resistance, or durability. The CNC machining shop you choose should have the ability to work with a variety of materials that are suitable for your robot parts.

Some of the common materials used for robot parts include:

- Aluminum alloys: Lightweight and strong, often used for structural components.

- Stainless steel: Durable and resistant to corrosion, used in joints and components that undergo high stress.

- Titanium: A strong, lightweight material often used for high-end or aerospace robots.

- Composites and plastics: For parts requiring insulation or flexibility.

Make sure the shop you choose has experience working with these materials and the proper machinery to handle them. Some shops may specialize in one material but may not have the capability to machine others. Ask for examples of previous work done with these materials to ensure they can meet your specific needs.

4. Technology and Machinery

The technology and equipment available at a CNC machining shop are crucial factors in determining the quality and efficiency of the parts produced. Look for a shop that has state-of-the-art CNC machines, including:

- Vertical and horizontal machining centers for precision parts.

- 5-axis CNC machines for producing complex, intricate geometries often required in robotics.

- Automated inspection tools like CMMs and laser scanners for accurate measurement of parts.

Additionally, ensure that the shop uses the latest CAD/CAM software for part design and machining. This software allows for high precision and helps avoid errors during the manufacturing process. The more advanced the shop’s technology, the more likely they will be able to handle the intricate and highly demanding designs often found in robotics.

5. Lead Time and On-Time Delivery

In the fast-paced world of robotics, delays can be costly. Whether you’re building a prototype or scaling up production for mass manufacturing, you need a CNC machining shop that can meet deadlines without compromising on quality.

Before committing to a shop, ask about their typical lead times. How long does it take them to produce custom parts for robots? Are they able to handle urgent orders if necessary? A good CNC machining shop will have a transparent process in place and should be able to provide a realistic timeline for your project.

If you’re working with a tight deadline or multiple milestones, ensure the shop has the resources and workforce to meet your needs. Some CNC machining shops can handle small batches, while others may specialize in high-volume runs—make sure their capabilities align with your requirements.

6. Customer Support and Communication

Effective communication is key to any successful project. From the initial consultation to final delivery, the CNC machining shop you choose should be easy to work with and responsive to your needs. Make sure they offer strong customer support, including:

- Project updates: Can they provide regular updates on the status of your parts?

- Consultation: Are they willing to offer advice and suggestions during the design process to improve the manufacturability of the parts?

- After-sales support: What kind of post-production support do they offer in case you encounter issues with the parts?

It’s important to find a shop that will listen to your needs and collaborate with you every step of the way. A responsive team will ensure that you’re never left in the dark and that any issues can be addressed promptly.

7. Cost and Value for Money

While cost is always an important factor in decision-making, it shouldn’t be the only consideration. In the world of CNC machining for robot parts, you get what you pay for. A low-cost shop might offer cheaper rates, but it could come at the expense of quality or precision.

Instead of just looking for the cheapest option, focus on the value for money. A shop that offers high-quality parts, excellent customer service, and fast lead times may be worth a higher price. Ultimately, investing in quality parts will save you time and money in the long run by avoiding costly mistakes or delays caused by faulty components.

Conclusion: Partnering with the Right CNC Machining Shop

Choosing the right CNC machining shop for your robot parts is essential for the success of your project. By focusing on experience, quality control, material capabilities, technology, lead times, and customer support, you can find a machining partner who will help bring your designs to life with precision and reliability.

At YL-Machining, we specialize in producing custom robot parts with high accuracy and attention to detail. If you’re looking for a CNC machining shop to handle your robot parts needs, we’re here to offer expertise and the highest quality service to meet your specific requirements.

Do you have any experiences or challenges when choosing a CNC machining shop for your robot parts? Let’s discuss in the comments below!