Did you know that as temperatures change, materials can expand or contract enough to affect the precision of manufactured components? In the world of CNC (Computer Numerical Control) machining, where precision is paramount, understanding the effects of thermal expansion is crucial. This hidden phenomenon can determine the success of machining processes for metals and plastics alike.

As industries continuously strive for accuracy and efficiency, thermal expansion has emerged as a critical factor influencing CNC machining operations. It affects tolerances, part integrity, and overall performance in ways that engineers and machinists must navigate carefully. In this comprehensive blog, we will explore the intricacies of thermal expansion in metals and plastics, their unique challenges in CNC machining, and effective strategies to mitigate these effects.

Understanding Thermal Expansion

What is Thermal Expansion?

Thermal expansion refers to the tendency of matter to change in volume in response to changes in temperature. Different materials exhibit different coefficients of thermal expansion (CTE), defined as the rate at which a material expands per unit length for a given temperature change. It’s a fundamental property of materials that engineers must consider, especially when designing high-precision components.

Why Does It Matter in CNC Machining?

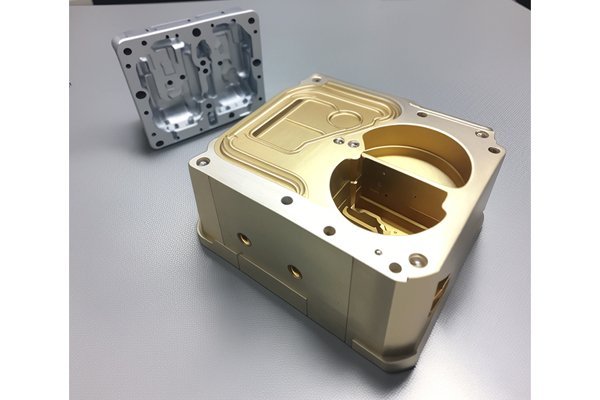

In CNC machining, the misalignment caused by thermal expansion can lead to tolerances exceeding acceptable limits. For instance, a metal part heated during machining operations can expand, leading to misfit issues when assembled with other components that have not expanded at the same rate. Similarly, plastics can also experience dimensional changes that impact their final performance. Therefore, understanding and controlling thermal expansion is essential for ensuring high-quality machined parts.

Exploring Different Materials

The Impact of Thermal Expansion on CNC Machining

Dimensional tolerances are paramount in CNC machining. Thermal expansion can lead to:

Overheating tools during machining can also induce thermal expansion. As tools heat up, they can expand, potentially affecting their geometries:

Most CNC machines are designed to maintain precision. However, thermal expansion can impact not only components but entire systems:

Solutions to Manage Thermal Expansion

Understanding thermal expansion is only half the battle; the other crucial step is applying solutions that effectively manage its impact. Here are some effective strategies:

Choosing the right materials for both the machined parts and the tooling can significantly mitigate the effects of thermal expansion:

Maintaining temperatures within controlled limits is perhaps the most straightforward solution:

Optimizing machining processes can help reduce the effects of thermal expansion:

Once machining is complete, certain finishing processes can help to achieve desired dimensions:

Future Trends and Considerations

As technology continues to advance, CNC machining processes will likely evolve to better accommodate thermal considerations. Emerging areas of research include:

The influence of thermal expansion on CNC machining is a critical aspect that requires careful consideration by engineers and machinists alike. By understanding how diverse materials respond to temperature changes and implementing strategic solutions, manufacturers can achieve high precision and quality in their machined components.

In summary, it is crucial to monitor dimensional tolerances, optimize processes, and select the right materials to counteract the effects of thermal expansion. With advancements in technology and a commitment to continual improvement, mastering thermal dynamics in CNC machining can lead to superior products capable of meeting stringent industry standards.

As you reflect upon the importance of this information, remember that precision is not merely a goal but a continuous journey in CNC machining. Understanding and addressing the challenges posed by thermal expansion is essential for those committed to excellence in their craft. Let this knowledge empower you to make informed decisions that will enhance your machining practices, leading to greater efficiency and product reliability.