Did you know that predictive maintenance can reduce machinery downtime by up to 30% and save up to 25% in maintenance costs? As industries continue to advance toward automation and data-driven decision-making, the implementation of predictive maintenance in aluminum CNC machining is revolutionizing not only how businesses manage their equipment but also how they approach productivity and efficiency.

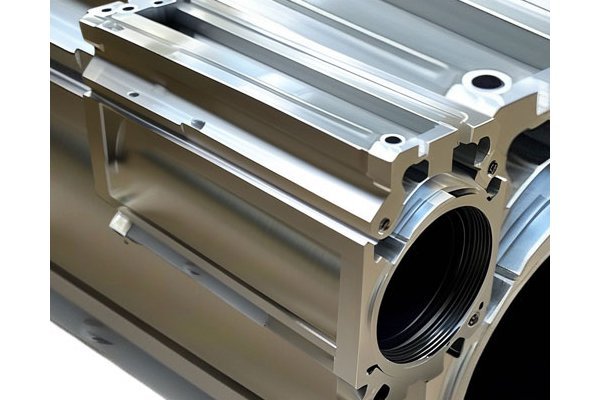

In the CNC (Computer Numerical Control) machining sector, especially with aluminum—a material known for its favorable weight-to-strength ratio—maintaining the longevity of machines while enhancing operational productivity is critical. This blog delves deep into the intricacies of predictive maintenance within aluminum CNC machining and provides you with detailed insights into its importance, methods, technologies, and best practices.

Understanding Predictive Maintenance

Predictive maintenance refers to the techniques and technologies employed to assess the condition of machinery and predict when maintenance should be performed. The goal is to reduce the probability of equipment failure and optimize the machinery’s lifecycle while minimizing downtime and operation costs.

Key Components of Predictive Maintenance

The Benefits of Predictive Maintenance in Aluminum CNC Machining

Aluminum CNC machines are typically costly investments; thus, extending their service life is critical. By effectively predicting failures and scheduling maintenance, businesses can ensure that their machines operate optimally and thus can significantly extend their usability.

Machine downtime can result in production delays, decreased productivity, and increased operational costs. Predictive maintenance allows for timely interventions, meaning that machines are serviced during scheduled breaks instead of unexpectedly failing during critical operations.

With predictive maintenance, operators can anticipate maintenance needs and schedule downtime in a way that least disrupts production. This strategic planning enables a more consistent workflow and increases overall productivity.

By maximizing uptime and minimizing failures, companies can significantly reduce operational costs associated with unscheduled maintenance. Predictive maintenance can help fix components before they fail, potentially saving on costs associated with emergency repairs and replacements.

Monitoring machine conditions and scheduling maintenance proactively also means a lower risk of accidents caused by equipment failure. This results in a safer working environment for workers and operators, which is critical in today’s regulatory landscape.

The Role of Technology in Predictive Maintenance

Modern aluminum CNC machines are outfitted with multiple sensors that collect critical data points, such as:

By integrating IoT (Internet of Things) devices, organizations can connect these sensors to a centralized processing system, aiding in real-time data analysis.

AI algorithms can analyze the conditions of various machine parameters, historical data, and usage patterns to accurately predict when a machine will need maintenance. Machine learning can further refine these predictions as more data is generated over time, thus improving system accuracy.

Utilizing cloud-based platforms enables companies to store and analyze massive quantities of data from various locations. This facilitates easier access to real-time machine health metrics, simplifies collaboration among teams, and enhances information sharing across departments.

Many predictive maintenance systems offer mobile applications that allow operators and maintenance personnel to monitor machine conditions in real-time from their smartphones or tablets. This flexibility enables quicker decision-making and facilitates timely interventions.

Implementing a Predictive Maintenance Program

Step 1: Assessment and Planning

Start by assessing current maintenance practices and identifying areas for improvement. Consider the types of CNC machines in use, their historical performance, and the typical wear-and-tear issues they face.

Step 2: Equip with Technology

Invest in sensors and monitoring technologies that align with the unique requirements of your aluminum CNC machines. Choosing the right technology is essential for effective condition monitoring and data collection.

Step 3: Data Integration

Merge data from different sources, such as CAD/CAM software, ERP systems, and other operational tools, to ensure a holistic view of your production processes. This integrated approach allows for a more accurate assessment of machine health.

Step 4: Data Analysis and Predictive Insights

Use data analytics tools to process machine-generated data. By analyzing historical patterns and current equipment health metrics, predictive insights can be generated for effective planning.

Step 5: Create a Maintenance Schedule

Develop a predictive maintenance schedule based on insights generated from data analysis. Include contingency plans for unexpected failures and strategies for optimizing equipment usage between maintenance intervals.

Step 6: Continuous Improvement

Make predictive maintenance a continuous process. Regularly assess the effectiveness of your maintenance strategies by collecting feedback, analyzing data trends, and finetuning your approach based on performance metrics.

Best Practices for Success

Predictive maintenance is revolutionizing aluminum CNC machining by increasing equipment lifespan, reducing the risk of failure, and improving overall productivity. As the industry continues to embrace advanced technologies—such as IoT, AI, and cloud computing—the role and effectiveness of predictive maintenance will only increase.

For business owners and operators in the CNC machining sector, investing time and resources in predictive maintenance isn’t just an option; it’s a strategic necessity. As competition grows and the demand for efficiency rises, a predictive maintenance strategy could make the difference between success and failure in today’s rapidly evolving market landscape.

By adopting the insights shared in this blog, manufacturers can elevate their operational effectiveness and ensure sustainable growth in the competitive field of aluminum CNC machining. Remember, it’s not just about keeping machines running; it’s about optimizing every aspect of your machining process for maximum productivity and reliability.