Did you know that more than 80% of all prototypes developed for rapid testing and market validation are produced using computer numerical control (CNC) machining techniques? Among these, CNC turning stands out as a pivotal method. This intriguing fact illuminates the essential role CNC turning plays in prototyping, particularly when it comes to enhancing mechanical properties. As industries from aerospace to automotive look for ways to optimize their prototypes, understanding how CNC turning can be leveraged to improve mechanical qualities becomes crucial.

In today’s competitive manufacturing landscape, developers and engineers are challenged to produce functional and efficient prototypes at an unprecedented speed. With customer expectations soaring, the mechanical integrity of these components is no longer optional but a necessity. This blog will delve into how CNC turning contributes to improving the mechanical properties of prototype components, offering a detailed exploration of technical solutions, benefits, and best practices.

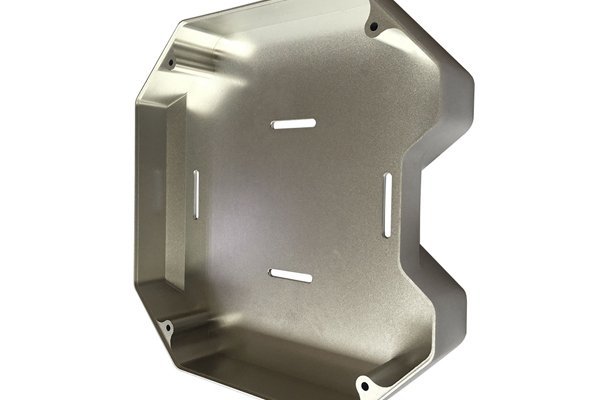

CNC turning is a machining process that involves rotating a workpiece against a cutting tool to achieve desired shapes and specifications. It’s primarily used for producing cylindrical components, such as shafts, bolts, and bushings. The precision it offers ensures that manufacturers can produce prototypes that closely resemble the final product.

Key aspects of CNC turning include:

Before diving into how CNC turning enhances mechanical properties, it is vital to understand what mechanical properties entail. In manufacturing, mechanical properties are attributes that typically include:

These properties are crucial as they directly impact the functionality, longevity, and reliability of a prototype. Enhanced mechanical properties can lead to more efficient designs and could also allow for reductions in material usage and costs.

To effectively improve the mechanical properties of prototype components, it is essential to consider the following solutions in conjunction with CNC turning:

4.

Selecting the right material is the first step in enhancing mechanical properties. Ideal materials should match the requirements of the final application. For example:

4.

Properly adjusting cutting parameters such as speed, feed rate, and depth of cut can mitigate issues such as part deformation and work hardening. General guidelines include:

4.

Choosing the right tooling materials and designs (e.g., carbide tools vs. high-speed steel) can influence performance. Tools should be designed for the specific material being turned, considering aspects like:

4.

Post-processing treatments can dramatically elevate the mechanical properties of CNC turned components. Options include:

CNC turning has extensive applications in various industries where mechanical properties are vital. Here’s a glance at how CNC turning influences several sectors:

5.

In the aerospace sector, lightweight and high-strength components are mandatory. CNC turning facilitates the precision engineering of parts such as turbine blades and fuselage components, ensuring reliability and performance in extreme conditions.

5.

CNC turned components like crankshafts, axles, and housing are integral to vehicle performance. Enhanced mechanical properties ensure durability and efficiency, leading to better fuel economy and safety.

5.

In the medical field, CNC turning is vital for producing precision components such as surgical instruments and implants. The mechanical integrity of these parts can be life-saving, making CNC turning an essential aspect of manufacturing.

As technology advances, CNC turning continues to evolve. Emerging trends include:

Enhancing the mechanical properties of prototype components is crucial for successful innovation in manufacturing. CNC turning not only allows for high precision and efficiency, but it also provides the means to optimize material properties, surface finishes, and production processes.

From precise machining to advanced post-processing treatments, the techniques explored in this blog serve as a foundation for enhancing mechanical performance across various prototypes. As industries continue to demand lighter, stronger, and more efficient components, leveraging CNC turning will prove invaluable.

Ultimately, understanding and applying these principles are not just beneficial; they are essential for staying competitive in an ever-evolving manufacturing landscape. By merging technology and technical know-how, companies can deliver prototypes that not only meet but exceed industry standards. The art of CNC turning is indeed a cornerstone of modern manufacturing, worth every moment of consideration and innovation.