Did you know that the global CNC machining market is forecasted to reach a staggering $100 billion by 2026? As industries become increasingly reliant on precise and efficient manufacturing processes, CNC machining has emerged as a cornerstone technology for creating prototype parts. In a world where accuracy can dictate product performance and safety, understanding how CNC machining enhances the dimensional consistency of prototype parts is crucial for engineers, manufacturers, and businesses alike.

The Importance of Dimensional Consistency

Dimensional consistency refers to how closely a manufactured part adheres to its specified dimensions throughout the production process. For prototype parts, ensuring this consistency is fundamental. It directly impacts:

Given this significance, it’s essential to explore how CNC machining tackles dimensional consistency challenges in prototype manufacturing.

Understanding CNC Machining

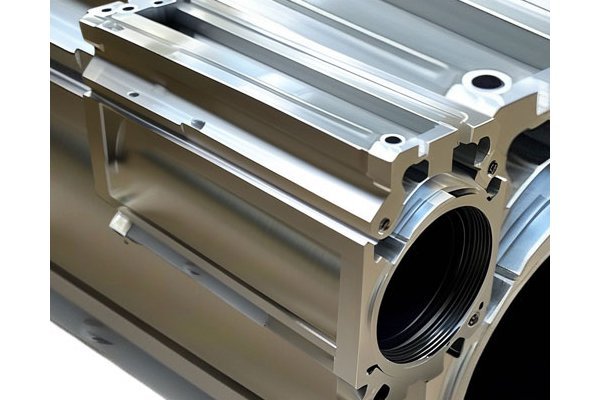

Before delving into how CNC machining improves dimensional consistency, let’s briefly cover what CNC machining entails. CNC stands for Computer Numerical Control, which is a method of automating machine tools via computers through programming code. This process is not just limited to milling; it extends to various machining practices including turning, drilling, and grinding.

How CNC Machining Works

How CNC Machining Improves Dimensional Consistency

CNC machining enhances dimensional consistency through several mechanisms:

Precision tooling refers to the high-quality cutting tools that CNC machines utilize. These tools are manufactured to very tight tolerances, enabling them to create intricate patterns and shapes with minimal deviation.

The heart of CNC machining lies in its computer-controlled operation. Unlike manual machining, where operator errors can introduce inconsistencies, CNC machines follow precise programmed instructions.

CNC machining includes meticulous control over various parameters such as feed rate, spindle speed, and depth of cut.

Quality assurance in CNC machining is not an afterthought; it’s embedded in the process. Advanced inspection techniques ensure that dimensional consistency is maintained throughout the production cycle.

Incorporating DFM principles in the design phase reduces dimensional inconsistency during machining.

The adoption of lean manufacturing techniques can further bolster dimensional consistency.

Advanced software allows for the simulation of the entire CNC machining process.

Maintaining industry standards throughout the CNC machining process is vital for ensuring quality and consistency.

Case Studies: Successful Implementation of CNC Machining

Case Study 1: Aerospace Component Prototyping

A leading aerospace company faced challenges in producing a series of prototype turbine blades. Initial attempts using conventional methods resulted in significant dimensional deviations. By transitioning to CNC machining, the company achieved tighter tolerances and precise repeatability across multiple prototypes. This successful adaptation saved time and costs while enhancing the operational efficiency of their product development cycles.

Case Study 2: Medical Device Manufacturing

A startup focused on producing medical devices needed prototypes that adhered strictly to regulatory standards. CNC machining allowed the company to produce complex geometries with high precision, ensuring compliance with FDA guidelines. In doing so, they not only improved their dimensional consistency but also accelerated their time to market.

CNC machining stands out as an innovative solution for enhancing the dimensional consistency of prototype parts. From precision tooling to real-time inspection methods, the processes involved in CNC machining are designed to mitigate variations, ensuring that prototypes are both functional and reliable.

The significant advantages brought forth by CNC technology—such as automation, controlled machining parameters, and adherence to industry standards—position it as a vital process in modern manufacturing practices. As industries continue to evolve, leveraging CNC machining will remain essential for businesses aiming for competitiveness in product accuracy and quality.

In today’s rapidly evolving market, understanding CNC machining’s role in improving dimensional consistency is paramount for engineers, manufacturers, and business strategists alike. Consider this: investing in CNC machining not only streamlines manufacturing processes but also bolsters overall product reliability, efficiency, and market adaptability. Thus, reflecting on how your operations can integrate CNC machining is not just worthwhile; it may very well dictate your success in the future landscape of manufacturing.