Did you know that the global CNC machining market is projected to reach $100 billion by 2025? This rapid growth is largely driven by the increasing demand for precision engineering across various industries, including aerospace, automotive, and medical devices. As manufacturers strive for higher efficiency and quality, the challenge of machining special materials—those that are easy to deform and difficult to process—has become a focal point in CNC machining.

In this blog, we will explore the intricacies of CNC machining when it comes to handling these challenging materials. We will delve into the techniques, tools, and strategies that manufacturers employ to ensure precision and quality, even when faced with the complexities of deformable materials.

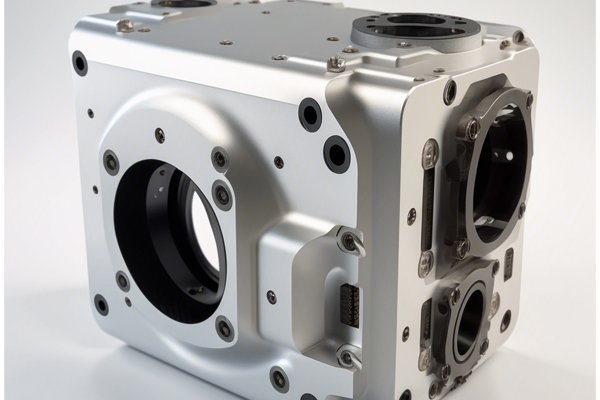

Understanding Special Materials in CNC Machining

What Are Special Materials?

Special materials refer to those that possess unique properties, making them challenging to machine. These can include:

Why Are They Difficult to Process?

The difficulty in machining these materials arises from several factors:

Techniques for Machining Special Materials

Choosing the appropriate cutting tools is crucial when machining special materials. Here are some considerations:

Adjusting cutting parameters is essential for successful machining. Key parameters include:

Advanced techniques can enhance the machining process for special materials:

CNC technology itself offers several advantages when machining special materials:

Case Studies: Successful Machining of Special Materials

Case Study 1: Machining Aluminum Alloys

A manufacturer faced challenges when machining a new aluminum alloy that was prone to deformation. By implementing a combination of cryogenic machining and specialized cutting tools, they were able to achieve the desired tolerances while minimizing material waste.

Case Study 2: Processing Polycarbonate

Another company struggled with machining polycarbonate, which tends to melt under high temperatures. By utilizing high-pressure coolant systems and adjusting their cutting speeds, they successfully produced high-quality parts without compromising the material’s integrity.

In conclusion, CNC machining of special materials that are easy to deform and difficult to process presents unique challenges. However, with the right tools, optimized cutting parameters, advanced techniques, and the capabilities of CNC technology, manufacturers can achieve precision and quality in their machining processes.

As the demand for high-performance materials continues to grow, understanding how to effectively machine these materials is more important than ever. By implementing the strategies discussed in this blog, manufacturers can not only improve their machining processes but also enhance their overall product quality.

Remember, the ability to handle special materials effectively can set a manufacturer apart in a competitive market. Embracing these techniques is not just a necessity; it’s a pathway to innovation and excellence in CNC machining.