Did you know that CNC (Computer Numerical Control) machining has revolutionized manufacturing, enabling the production of complex parts with remarkable precision? In fact, studies indicate that CNC machining can yield tolerances as tight as ±0.001 inches, making it a game-changer for industries that demand high accuracy. For manufacturers working with materials like stainless steel and brass, understanding CNC machining’s capabilities is crucial not only for enhancing production quality but also for optimizing efficiency.

In this blog, we will delve deeply into how CNC machining achieves unparalleled accuracy and efficiency when handling stainless steel and brass materials. We’ll explore key techniques, innovative technologies, and recommended practices while addressing industry-specific challenges. Whether you are a seasoned engineer, a project manager, or a business owner, this comprehensive guide will equip you with valuable insights and strategies to enhance your CNC machining processes.

Understanding CNC Machining

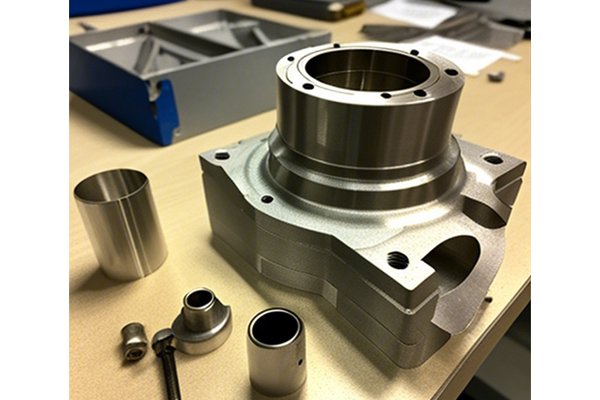

CNC machining is a subtractive manufacturing process in which computer-controlled machines remove material from a workpiece to achieve a desired shape and form. The CNC machines interpret a design created in CAD (Computer-Aided Design) software and execute it with a high degree of precision.

Why Stainless Steel and Brass?

Both stainless steel and brass are popular choices in various industries, from automotive to aerospace. Their unique properties cater to specific requirements:

Factors Influencing Accuracy and Efficiency in CNC Machining

Achieving accuracy and efficiency in CNC machining involves several key factors. Understanding and optimizing these factors can vastly improve production outcomes.

Selecting the right cutting tool is critical. The tool must be appropriate for both the material—stainless steel or brass—and the specific machining operation—milling, turning, or drilling.

Correctly setting machining parameters such as feed rate, spindle speed, and depth of cut greatly impacts performance.

Using the right coolant or lubricant can greatly influence efficiency and the quality of the finish.

Regular calibration of CNC machines is essential for ensuring consistent accuracy. Maintenance protocols should include:

CNC Machining Techniques for Precision

There are specific techniques that can enhance accuracy and efficiency in CNC machining, particularly when dealing with hard materials like stainless steel and non-ferrous metals like brass.

Implementing advanced tool path strategies can optimize machining processes. Techniques like climb milling, where the cutter rotates in the same direction as the feed travel, can produce a better surface finish and extend tool life.

Using simulation software like CAD/CAM can help visualize the machining process, allowing manufacturers to identify potential issues before production. This proactive approach can save time and reduce errors.

Investing in in-process measurement systems can significantly enhance accuracy. Systems such as laser scanning or touch probes allow for real-time measurement, ensuring that the dimensions of the parts remain within tolerance.

Potentials Challenges and Solutions

While CNC machining offers many benefits, challenges can arise, especially when working with stainless steel and brass.

Tool wear is a common issue that affects machining accuracy. Regular monitoring and the implementation of tool wear sensors can mitigate this issue, allowing for timely tool replacement.

Both stainless steel and brass can undergo thermal deformation. Employing cooling techniques and optimizing cutting speed can mitigate heat generation and subsequently reduce thermal distortion.

Managing chips effectively is crucial for maintaining efficiency and accuracy. Implementing proper chip removal and recycling systems can help prevent bottlenecks and ensure a clean cutting environment.

Real-World Applications: Case Studies

To illustrate the effectiveness of CNC machining techniques with stainless steel and brass, we will explore a couple of case studies showcasing successful implementations.

Case Study 1: Aerospace Component Manufacturing

Company A, a manufacturer of aerospace components, faced challenges with machining stainless steel brackets with tight tolerances. By investing in advanced CNC machines equipped with in-process measurement systems and adopting optimal machining parameters—in conjunction with high-quality tools—they were able to increase their production yield by 30% while maintaining a tolerance of ±0.001 inches.

Case Study 2: Electrical Fittings Production

Company B specialized in producing brass electrical fittings and struggled with surface finish quality. By switching to specialized brass coolants and optimizing their machining operations using advanced tool path strategies, they improved surface finish significantly, achieving a Ra of 0.8 micrometers, leading to higher customer satisfaction and reduced rework.

In conclusion, achieving accuracy and efficiency in CNC machining when working with stainless steel and brass requires a multifaceted approach involving careful tool selection, precise machining parameters, strategic use of coolants, diligent maintenance, and the implementation of innovative strategies.

The techniques discussed in this blog not only address common challenges but also pave the way for enhanced productivity and superior quality in manufacturing. Understanding how CNC machining operates on these levels is essential for any professional looking to optimize their processes and remain competitive in today’s fast-paced manufacturing landscape.

Remember, the precision with which pieces are manufactured has far-reaching implications—not just for production timelines and costs but also for ensuring the reliability and performance of the final product. Thus, the importance of mastering CNC machining processes should not be underestimated.

By integrating advanced machining techniques and adhering to best practices, your operations can achieve unparalleled levels of accuracy and efficiency, setting the stage for continued success and growth in your respective field.