Introduction

Imagine standing at the edge of a bustling manufacturing facility, where precision meets innovation, and the air is alive with the hum of machines. The smell of freshly machined aluminum fills the air, and before you, rows of intricate parts await assembly. This is the world of CNC aluminum extrusion

But what exactly is CNC aluminum extrusion, and why has it become the gold standard in aluminum manufacturing? In this comprehensive guide, we’ll not only delve into the intricacies of CNC (Computer Numerical Control) aluminum extrusion but also explore its applications, benefits, and best practices. Whether you’re a seasoned engineer, a curious DIY enthusiast, or simply someone interested in how modern manufacturing works, this article is your go-to resource!

What is CNC Aluminum Extrusion?

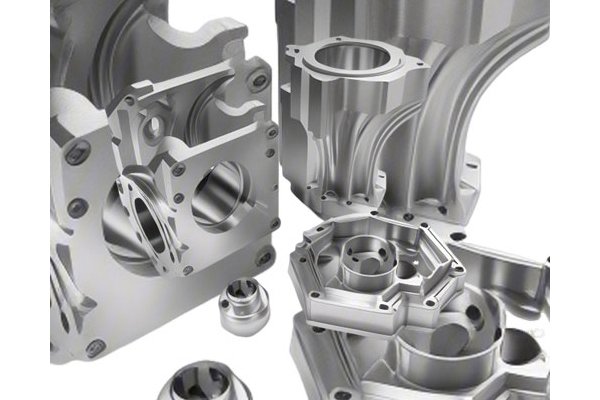

To truly grasp the concept of CNC aluminum extrusion, let’s break it down. In simple terms, aluminum extrusion is the process of transforming aluminum alloy into objects with a defined cross-sectional profile. This involves pushing a heated aluminum billet through a die to create long lengths of material with specific shapes.

CNC machining comes into play when precision is required. By using computer-controlled machines, manufacturers can achieve extremely tight tolerances and intricate designs. So, when you combine CNC with aluminum extrusion, you get a powerhouse of precision engineering that’s both versatile and efficient.

The Process: How Does it Work?

The Importance of Precision

Precision is the backbone of CNC aluminum extrusion. In industries such as aerospace and automotive, even the slightest variance can lead to critical failures. Would you trust a car manufactured with off-spec parts? Probably not. The beauty is that CNC machining can achieve tolerances as tight as ±0.001 inches, ensuring consistency and reliability in every piece produced.

Applications of CNC Aluminum Extrusion

From the automotive industry to electronics and construction, CNC aluminum extrusion has a broad spectrum of applications. Let’s dive into some of the key areas where it truly shines.

In the aerospace industry, weight and strength are essential. Aluminum is favored because it’s lightweight yet incredibly strong. Components like frames, brackets, and enclosures, all benefit from CNC aluminum extrusion, ensuring safety and performance at high altitudes.

The automotive sector has seen a significant shift towards lightweight materials to improve fuel efficiency. Extruded aluminum parts, from chassis components to engine blocks, are crucial. Utilizing CNC technology in manufacturing these parts allows for superior fitment and performance.

Ever wondered why your smartphone feels so sleek? A significant part of that sleek design comes from custom aluminum housings and frames produced through CNC aluminum extrusion. The precision required ensures that every button, port, and camera fits exactly where it should.

In construction, aluminum extrusions are used for window frames, doors, and structural components. With CNC precision, these elements can be customized to fit unique architectural designs, blending functionality with aesthetic appeal.

Lastly, industrial equipment such as conveyor systems and machine frames often utilize CNC aluminum extrusion for their lightweight yet durable characteristics. These components withstand heavy loads while enabling smoother operations.

Benefits of CNC Aluminum Extrusion

Now that we’ve uncovered what CNC aluminum extrusion is and where it’s used, let’s talk about the myriad benefits it offers.

One of the standout advantages of CNC aluminum extrusion is its high degree of customization. Manufacturers can create virtually any shape or profile to meet specific design needs. This flexibility is akin to having a tailor make a suit just for you!

When you consider the entire manufacturing process, CNC aluminum extrusion can be cost-effective. The ability to create complex shapes in a single operation reduces labor costs. Moreover, aluminum’s recyclability means that leftover materials can be repurposed, minimizing waste.

Aluminum is inherently lightweight, making it an excellent choice for applications where weight reduction is vital. Yet, it maintains a strength comparable to steel, proving that you can have the best of both worlds.

Another notable benefit is aluminum’s natural resistance to corrosion. This makes CNC aluminum extrusions ideal for outdoor applications or environments where exposure to elements is a concern.

As mentioned earlier, CNC machining allows for extremely high tolerances, leading to precise fits and finishes. This reliability is pivotal in industries where safety is paramount.

Best Practices for CNC Aluminum Extrusion

If you’re considering CNC aluminum extrusion for an upcoming project, there are best practices to ensure optimal results. Here are some tips to keep in mind:

Different aluminum alloys have varying properties, affecting everything from strength to ductility. Work closely with your supplier to select the most suitable alloy for your application.

When designing your components, ensure that your designs are optimized for extrusion. Avoid intricate features that may be challenging to produce; simpler designs often yield better results.

Clearly define tolerances and specifications early in the process. Accurate communication can prevent costly mistakes and ensure that the final product meets your expectations.

Partnering with skilled machinists is vital. They understand the intricacies of CNC aluminum extrusion and can guide you in optimizing the manufacturing process to reduce the risk of errors.

After machining, consider surface finishing options such as anodizing or powder coating to enhance durability and appearance. This step provides added protection against corrosion and wear.

Conclusion

CNC aluminum extrusion is more than just a manufacturing process; it’s a symphony of technology, precision, and creativity that drives innovation across various industries. From aerospace to electronics, this process has revolutionized how we produce components, allowing us to push the boundaries of what’s possible.

As you navigate the world of CNC aluminum extrusion, remember that knowledge is power. Understanding the intricacies of the process, its applications, and best practices will empower you to make informed decisions and embrace the endless possibilities it offers.

So, whether you’re designing a new product, considering materials for a project, or simply exploring the fascinating realm of manufacturing, CNC aluminum extrusion is a treasure trove of opportunities just waiting to be discovered.

Take the plunge, engage in the conversation, and let your journey in precision engineering begin! For every project, there’s a pathway to excellence, and CNC aluminum extrusion is that pathway paved with strength, accuracy, and endless potential.