Did you know that the automotive and aerospace industries alone account for nearly 40% of all CNC machining operations globally? This fascinating statistic underscores the importance of material selection in CNC processing, as each industry has its distinctive requirements that influence which materials are preferable for specific applications. But why does this matter? The wrong choice of material can lead to failure in functionality, increased costs, or even catastrophic failures—especially when dealing with components requiring high precision and reliability.

CNC (Computer Numerical Control) machining is a revolutionary manufacturing process that has transformed how products are produced across various sectors. However, the choice of material is integral to the success of CNC machining. This blog aims to explore how different industries influence material selection requirements in CNC processing and how businesses can navigate these nuances effectively.

—

1.1 What is CNC Machining?

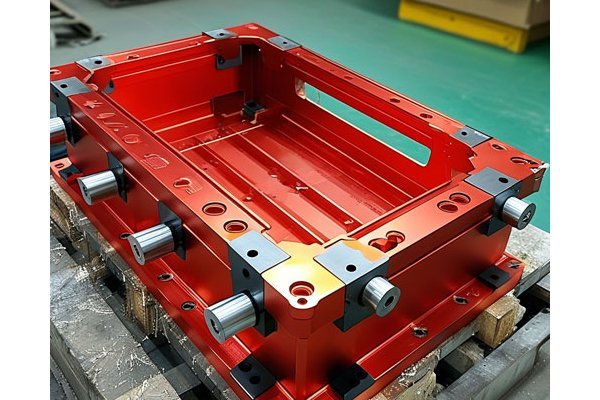

CNC machining is a subtractive manufacturing process whereby material is removed from a workpiece using a variety of cutting tools controlled by a computer. This technology offers exceptional precision, consistent product quality, and the ability to work on complex geometries, making it indispensable in modern manufacturing.

1.2 Importance of Material Selection

Material selection in CNC machining is crucial because the chosen material directly impacts factors such as:

Factors such as cost, availability, and environmental considerations also come into play.

—

2.1 Aerospace

In aerospace and aviation, material selection is heavily influenced by weight, strength, and fatigue resistance. Here are some specifics:

2.2 Automotive

The automotive industry prioritizes materials that provide durability and safety while also being cost-effective.

2.3 Medical Devices

For the medical device industry, the selection process is dictated by stringent regulatory standards, biocompatibility, and functionality.

2.4 Electronics

In electronics, materials must facilitate conductivity and ensure heat dissipation, especially in high-performance devices.

—

3.1 Specific Requirements Per Industry

Different industries come with unique requirements, and the implications for material selection are vast.

3.2 Adaptability and Flexibility

Manufacturers must consider how materials can be adapted to meet the needs of various projects. For example, a company in the medical device sector may explore a hybrid manufacturing approach that incorporates different materials to achieve certain aesthetic or functional outcomes.

—

4.1 Establishing Core Criteria

To navigate the complexity of material selection, consider the following core criteria:

4.2 Collaboration with Material Scientists

Collaboration with experts like material scientists can offer insights into innovative materials. These specialists can assist in evaluating unique characteristics that would enhance product performance.

4.3 Prototyping and Testing

Prototyping is invaluable in determining whether a selected material meets industry standards and performance expectations.

4.4 Continuous Education and Training

Providing ongoing training for engineers and manufacturing specialists ensures they stay updated on the latest material innovations and machining technologies.

—

As technology evolves, so too does the landscape of materials used in CNC machining.

5.1 Advanced Materials

Emerging materials such as carbon fiber composites and advanced alloys are gaining traction in various industries. They offer properties that were previously unattainable, expanding the possibilities for design and functionality.

5.2 Sustainable Options

Sustainability is a rising concern impacting material selection. Future-focused companies will lean into recycling and renewable materials, reducing their carbon footprint and meeting consumer demand for environmentally responsible products.

5.3 Nanotechnology and Smart Materials

Materials imbued with nanotechnology can offer significant enhancements in properties such as strength, heat resistance, and electrical conductivity. Meanwhile, smart materials could allow for self-repair or adaptable characteristics based on environmental stimuli.

—

In the realm of CNC processing, understanding how different industries influence material selection requirements is vital for achieving optimal results. From aerospace to automotive, medical devices to electronics, each sector presents its unique challenges and opportunities that directly affect material choices.

As a manufacturer or engineer, leveraging the insights provided in this blog can aid you in making informed decisions when selecting materials. By establishing clear criteria, collaborating with experts, embracing prototyping, and committing to continuous education, you can unlock the full potential of your CNC machining processes.

In an ever-evolving landscape characterized by innovation and pressure for sustainability, staying vigilant about material selection is more important than ever. Remember, the right material can lead not only to improved efficiency and performance but also safeguard your business’s reputation in a competitive marketplace.

Consider this: in a world driven by technology, the materials we choose ultimately shape the future of manufacturing. Now is the time to think critically about your material selections and the profound impact they can have on your industry.