—

Opening Remarks

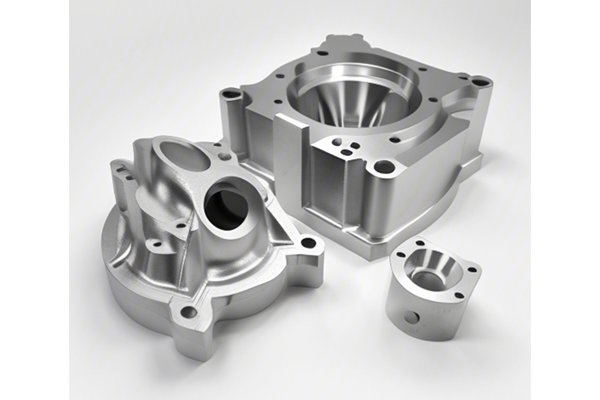

At the heart of precision manufacturing lies a fascinating world of technology that many are unaware of. The age of CNC (Computer Numerical Control) machining has transformed the industry, and among the unsung heroes of this evolutionary tale are CNC turned parts. Have you ever wondered how these intricate components play a role in producing high-quality products, from the smallest electronic devices to vast industrial machinery? If you’re curious about this captivating process and its impact on precision manufacturing, buckle up! We’ll delve deep into the realm of CNC turned parts, exploring their definition, applications, benefits, and much more. By the end of this journey, you’ll have a robust understanding of how these components contribute to modern manufacturing and, quite possibly, inspire you to explore further!

What Are CNC Turned Parts?

Before we dive into the nitty-gritty, let’s clarify what CNC turned parts actually are. Imagine a giant lathe – a machine that can take a simple block of material, like metal or plastic, and transform it into precisely shaped components. This process is known as turning, where the material is rotated against a cutting tool to create cylindrical parts.

Now, when we add the “CNC” into the mix, it means that this process is controlled by a computer program. This allows for incredibly precise cuts, even at high speeds. Think of it as giving the lathe a brain, allowing it to execute complex cuts and designs with minimal human intervention.

The CNC Turning Process: A Closer Look

So, how does this fancy CNC turning work? Let’s break it down.

Why Are CNC Turned Parts Important?

You might be wondering, “Okay, but why should I care about CNC turned parts?” Great question! Let’s explore some key reasons that highlight their importance in modern manufacturing:

Applications of CNC Turned Parts

CNC turned parts find application in a myriad of industries. Let’s take a closer look at a few sectors where these components thrive:

Aerospace

Aerospace components require the utmost precision and reliability. CNC turned parts are used in everything from turbine blades to landing gears. The high standards of safety and performance in this industry make the precision of CNC turning indispensable.

Automotive

From intricate engine parts to exterior trims, the automotive industry relies heavily on CNC turned components. The ability to produce complex geometries and ensure uniform quality makes these parts crucial in modern vehicle manufacturing.

Electronics

In the world of electronics, the miniaturization of components has become a trend. CNC turned parts, being highly precise, allow manufacturers to create compact and intricate electronic housing, connectors, and other essential components.

Medical Devices

In healthcare, the precision of CNC turned parts can be a matter of life and death. Medical devices such as surgical instruments and prosthetic limbs require high tolerances, making CNC turning a preferred choice in this sensitive industry.

The Benefits of Using CNC Turned Parts

How is CNC Turning Different From Other Machining Processes?

You may wonder how CNC turning stacks up against other methods like milling or drilling. Let’s take a quick tour through these layers of machining:

While turning is specialized for specific cylindrical shapes, milling and drilling have a broader range of applications – but that’s a whole other topic for discussion!

The Future of CNC Turning

As we look toward the future, CNC turning technology continues to evolve. With advancements in automation and artificial intelligence, the landscape of precision manufacturing is changing rapidly.

Smart Manufacturing: Imagine a world where machines can “talk” to each other, sharing data in real-time to optimize production. That’s what smart manufacturing is all about! Digital twins and IoT (Internet of Things) technology integration are paving the way for more efficient and adaptable manufacturing processes.

Sustainability: As industries face increasing pressure to minimize waste, CNC turning can also pivot in this direction. By optimizing machining processes and materials usage, manufacturers can reduce their carbon footprints and promote sustainable practices.

Common Questions About CNC Turned Parts

Need clarification on CNC turned parts or have a burning question? Let’s address a few common queries that may arise:

How long does it take to make CNC turned parts?

The time can vary greatly depending on the complexity and size of the part. Simple components might take just a few hours, while more intricate designs could take days. The good news is that CNC technology allows many parts to be produced simultaneously, enhancing overall efficiency.

What materials are commonly used for CNC turned parts?

CNC turning can work with a variety of materials, including metals (like aluminum, steel, and brass), plastics (such as acrylic and nylon), and composites. The choice of material often depends on the application and required properties.

Are CNC turned parts more expensive than traditionally manufactured parts?

While the initial investment in CNC technology can be substantial, the overall cost tends to balance out over time due to reduced labor, waste, and increased efficiency. Plus, the quality and precision often justify the price!

Conclusion: The Transformative Power of CNC Turned Parts

In conclusion, CNC turned parts are more than just components of a larger mechanism. They are vital pieces of a puzzle that allow industries to thrive in a competitive world. Their high precision, versatility, and ability to streamline production processes have revolutionized modern manufacturing.

As we wrap up this journey through the fascinating landscape of CNC turned parts, I encourage you to keep exploring. Whether it’s diving deeper into CNC technology, learning about more manufacturing techniques, or examining the endless applications in your everyday life, there’s always more to discover!

So, what do you think? Are CNC turned parts now on your radar? Feel free to reach out if you have more questions or if you’d like to discuss specific applications or technology. Learning is an ongoing journey, and I’m here to support you every step of the way!

—

I hope you’ve found this exploration engaging and insightful! With every new piece of knowledge, you’re one step closer to mastering complex concepts in manufacturing. Thank you for joining this knowledge-sharing adventure!