Opening

Did you know that over 90% of manufacturing professionals believe that a well-designed CAD model is key to achieving precision and efficiency in CNC machining? In today’s rapidly evolving manufacturing landscape, the accuracy of Computer Numerical Control (CNC) machining directly relies on the quality and efficiency of the CAD models used. This blog explores in depth how to design an efficient CAD model tailored for CNC machining, ultimately leading to enhanced accuracy and productivity in manufacturing processes.

Understanding CAD and CNC Machining

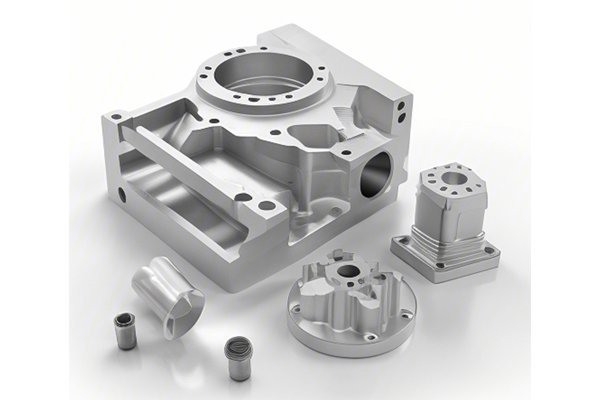

Computer-Aided Design (CAD) refers to the utilization of software tools to facilitate the creation, modification, analysis, or optimization of a design. The CAD model serves as the blueprint for CNC machining, guiding the machines that manufacture parts with precision. CNC machining, on the other hand, employs automated tools, guided by the CAD model, to cut, mill, drill, and shape various materials. Together, CAD and CNC technologies foster an integrated approach that streamlines production and maximizes performance.

However, the effectiveness of this approach hinges on the quality of the initial design. Hence, mastering how to design an efficient CAD model becomes paramount.

Key Elements of Designing an Efficient CAD Model

A well-thought-out model begins with optimized geometry. Creating a model that aligns with the capabilities of the CNC machine enhances the machining process. Consider the following strategies:

The choice of material directly influences the design. Different materials react uniquely to the machining process, which in turn affects the choices made during the CAD design phase.

Effective tool path planning is integral to a successful CNC machining process. The tool path dictates how the machine moves through the material, and thus it influences both accuracy and efficiency.

Today’s CAD software offers numerous features that can assist in optimizing designs:

Bridging the gap between designers and machinists can lead to more efficient designs. Collaboration can ensure that the CAD model is practical from the machining perspective, thus:

Prototyping allows you to identify design flaws that won’t be apparent until physical testing occurs. Rapid prototyping technologies, like 3D printing, can yield quick results.

Designing efficient CAD models is not just a technical requirement; it’s a critical step toward elevating quality, reducing production costs, and enhancing overall productivity in CNC machining. By focusing on geometry optimization, thoughtful material selection, strategic tool path planning, advanced CAD software features, collaborative efforts with machinists, and robust prototyping practices, manufacturers can overcome common challenges to achieve more accurate and effective machining outcomes.

In a world where precision matters more than ever, the importance of aligning CAD design strategies with CNC machining capabilities cannot be overlooked. Whether you’re a seasoned professional or a newcomer in the field, a thorough understanding of how to create effective CAD models is vital. The synergy between CAD and CNC can unlock unprecedented levels of quality and efficiency in manufacturing – and it all starts with the design process.

Our exploration of this topic serves as an invaluable reminder for every engineer and manufacturer: The right foundation in design not only sets the stage for successful machining but also fosters innovation within the industry. With advancements in technology, now is the perfect time to reconsider your design strategies and embrace methodologies that champion efficiency and excellence in CNC machining.