In the heart of today’s manufacturing evolution lies a technological marvel: Custom CNC (Computer Numerical Control) parts. These engineered components are not just products; they are facilitators of innovation, efficiency, and unparalleled precision. At YL Machining, we take pride in pushing the boundaries of what’s possible by offering an extensive range of custom CNC solutions tailored to meet the dynamic needs of industries across the spectrum.

But what exactly makes custom CNC parts a game-changer in manufacturing? In this article, we’ll explore the intricacies of CNC machining, delve into the transformative capabilities of custom parts, and illuminate how YL Machining stands at the forefront of this cutting-edge field.

The Essence of CNC Machining

CNC machining is a modern manufacturing process that uses computer-controlled machines to produce precise parts from a variety of materials. Unlike traditional machining, which relies heavily on manual operations, CNC machining minimizes human error and offers a repeatable, scalable approach to production. Typically, CNC milling, turning, and routing processes form the backbone of CNC services.

The Evolution of CNC Technology

The journey of CNC technology began in the 1950s with the development of the first computer-controlled machines. Over the decades, advancements in technology have led to a shift from mechanical to digital control, paving the way for complex designs that were previously unattainable. Today, CNC machines rely on sophisticated software and high-speed processors, allowing for intricate designs that can be executed with exactitude.

The Role of CAD and CAM

Central to CNC machining are CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems. CAD involves creating detailed 3D models of parts, enabling designers to visualize their creations thoroughly before production begins. Meanwhile, CAM converts these designs into actionable code that directs the CNC machinery on how to execute the cuts and finishes.

Why Custom CNC Parts?

Unique Design Requirements

In an age where one-size-fits-all solutions are increasingly outdated, custom CNC parts offer unparalleled flexibility in design. Whether a business requires specialized components for complex assemblies or small-batch runs, custom CNC manufacturing allows for adaptations that standard parts cannot fulfill. At YL Machining, we understand that no two businesses are the same, and we tailor our services to meet unique specifications and challenges.

Superior Precision and Quality

One of the most compelling reasons to opt for custom CNC parts is the precision they offer. With minimal tolerances typically as tight as ±0.005 inches, CNC machining delivers parts that fit together seamlessly and perform flawlessly. This quality is particularly essential in industries such as aerospace, automotive, and medical, where reliability is paramount.

Cost-Effective Solutions

While the initial investment in custom CNC parts may appear higher than standard components, the long-term savings are substantial. By mitigating errors and reducing the amount of wasted material, precision manufacturing results in a lower cost per part, especially in high-volume production runs. Additionally, custom parts can lead to improved efficiency and lesser operational downtime—factors that can significantly enhance profit margins.

Faster Turnaround Times

At YL Machining, we leverage state-of-the-art technology and a skilled workforce to streamline the entire production process. Our automated systems enable rapid prototyping and timely delivery of custom CNC parts. In today’s fast-paced business environment, speed matters, and we understand that our clients rely on us to meet tight deadlines without sacrificing quality.

Enabling Innovation

Custom CNC parts empower manufacturers to pursue innovation. With the ability to create prototypes and iterate designs swiftly, businesses can experiment with new concepts and quickly adapt to market demands. This agility not only enhances a company’s competitive edge but also cultivates a culture of creativity and invention.

Applications of Custom CNC Parts

Custom CNC parts find applications across a multitude of industries. Let’s delve into some of the key sectors where our services at YL Machining have made a significant impact.

Aerospace Industry

In aerospace, precision is non-negotiable. Custom CNC parts are used in critical components, ranging from complex brackets to turbine blades. The stringent quality standards in this sector demand reliable suppliers like YL Machining that adhere to rigorous compliance measures, ensuring safety and performance.

Automotive Industry

As the automotive industry shifts toward electric vehicles and advanced driver-assistance systems (ADAS), the need for custom CNC parts has surged. From engine components to interior fittings, manufacturers rely on precision-engineered parts to meet the evolving demands of the market.

Medical Devices

The medical industry hinges on accurate and reliable tools and components. Custom CNC machining is often employed in the production of surgical instruments, implantable devices, and diagnostic equipment. YL Machining’s commitment to quality and precision means we help healthcare innovators deliver life-saving solutions.

Electronics

In the electronics sector, where minuscule dimensions rule, custom CNC machining is the ideal solution to manufacture custom housings, circuit board layers, and connectors. The ability to produce parts with great detail makes us a trusted partner for electronics manufacturers.

Industrial Machinery

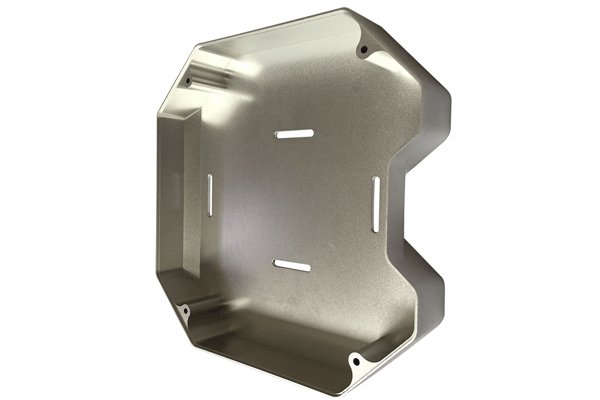

Last but not least, custom CNC parts play a vital role in fabricating components for industrial machinery. From gears to housings, having the right CNC parts can mean the difference between efficient operations and costly downtime.

The YL Machining Advantage

At YL Machining, our dedication to excellence is reflected not just in the quality of our products but also in the connections we build with our partners and clients. Here are some defining features that set us apart in the custom CNC machining landscape:

Expertise and Experience

With years of experience in the industry, our team comprises experts well-versed in the latest machining techniques. Our engineers and machinists work collaboratively to address every client’s unique challenges, ensuring that we deliver precisely what they need.

Advanced Technology

We employ cutting-edge CNC machines with 5-axis capabilities, enabling us to produce intricate and complex parts. This technology allows us to handle a diverse range of materials, including metals, plastics, and composites, broadening the scope of what our clients can achieve.

Quality Assurance

Our quality control processes are meticulous, guaranteeing that each custom part meets or exceeds industry standards. From initial production to final inspection, we adhere to best practices that ensure consistency and reliability throughout the production process.

Customer-Centric Approach

At YL Machining, our clients are at the core of everything we do. We listen to their visions, understand their pain points, and provide tailored solutions that meet their specifications. Our commitment to transparent communication and support has cultivated lasting partnerships.

Comprehensive Services

We offer a full suite of services, from design and prototyping to mass production and post-production support. Whether small or large volumes are required, our flexibility ensures we can meet the demands of projects in any size.

Looking Ahead: The Future of CNC Machining

As technology continues to evolve, so too will the possibilities behind custom CNC machining. The future holds exciting advancements such as additive manufacturing (3D printing), artificial intelligence, and smart manufacturing systems that utilize IoT (Internet of Things) for real-time performance monitoring. These innovations promise to further enhance precision, reduce costs, and streamline production.

Embracing Sustainability

Additionally, as environmental awareness becomes increasingly crucial, the role of sustainable practices in CNC machining will become paramount. At YL Machining, we are committed to incorporating eco-friendly materials and processes that align with sustainable manufacturing principles, ensuring our contributions can protect the planet while driving business success.

Custom CNC parts play a pivotal role in the modern manufacturing landscape—setting the stage for innovation, excellence, and transformative capabilities across various industries. At YL Machining, we harness the power of precision engineering to support the ambitions of our clients, driving their visions from preliminary designs to final products.

By choosing custom CNC parts, businesses don’t just invest in components; they invest in a future of possibility—a future where the limits of creativity and functionality extend beyond the ordinary. As we navigate this ever-evolving landscape together, we invite you to partner with us on your journey toward manufacturing excellence.

Are you ready to unlock endless possibilities with custom CNC parts?