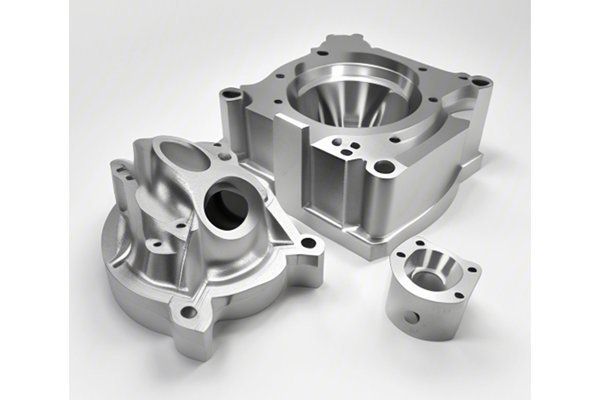

In a world where precision reigns supreme, the role of custom CNC machining in metal fabrication cannot be overstated. At YL Machining, we pride ourselves on our ability to harness the power of advanced technology to bring your unique concepts to life. As fabricators and innovators, we understand that our clients are not just looking for components—they seek solutions that embody quality, precision, and attention to detail. So, how does custom CNC machining facilitate this transformation? Join us as we delve into the intricacies of this fascinating process, explore its benefits, and demonstrate how YL Machining stands at the forefront of this technological revolution.

Understanding CNC Machining: The Basics

CNC, or Computer Numerical Control, machining refers to the automated control of modern machining tools by means of a computer. CNC machines execute precise cutting, milling, turning, and drilling operations guided by programmed codes. While traditional machining relies on manual operations, CNC machining reduces human error and enhances the production and repetition capabilities of various materials, particularly metals.

Types of CNC Machining Processes

At YL Machining, we employ a suite of CNC machining methods tailored to meet the diverse needs of our clients. Here are a few of the most common types:

The Machining Passport: Precision at Its Core

Behind the creativity of custom pieces lies a critical foundation—precision engineering. Our process begins with an in-depth understanding of the client’s requirements, followed by a well-articulated design phase rooted in CAD (Computer-Aided Design). This stage acts as the passport to our machining journey. Each component designed via CAD transforms into numerical codes that CNC machines interpret and execute, ensuring that what was envisioned on the screen is perfected on the shop floor.

The YL Machining Advantages: Why Custom CNC Machining?

In metallurgy, a fraction of a millimeter can make a world of difference. CNC machining delivers accuracy to an impressive tolerance level, typically within ±0.005 mm. This unmatched precision ensures that each component adheres to its design specifications, resulting in higher-quality products.

One of the standout features of custom CNC machining is its versatility. At YL Machining, we utilize a wide array of materials ranging from aluminum and stainless steel to exotic metals and plastics. This adaptability allows us to cater to industries such as aerospace, automotive, medical, and more.

Custom CNC machining allows for seamless transitions between prototype development and full-scale production. With rapid prototyping capabilities, we can swiftly create a small run of components to assess design effectiveness, enabling modifications before entering a larger production cycle. This scalability factor mitigates risks and ensures a smoother rollout of new products.

While the initial investment for CNC machining might be higher than traditional methods, the long-term savings are significant. Custom machinery reduces waste material, enhances automation in large production runs, and minimizes manual labor costs—translating into lower overall production expenses.

With our advanced CNC technology, we can generate parts rapidly and efficiently. As a result, YL Machining proudly offers reduced lead times, facilitating timely deliveries that align with customer schedules.

The Customization Element: Tailoring Solutions for Unique Needs

At YL Machining, we understand that no two projects are alike; therefore, customization is key. Custom CNC machining enables us to cater to individual requirements, from small-scale R&D projects to expansive manufacturing contracts.

Custom Finishes and Treatments

Beyond just machining, our services include various finishing processes that enhance both the aesthetic and functional qualities of your parts. Options such as anodizing, plating, painting, and passivation can protect against corrosion and wear, ensuring longevity and optimal performance.

Design Collaboration

Our talented engineers work hand in hand with clients throughout the design process. By incorporating client feedback and insights, we create products tailored precisely to meet their application requirements.

Quality Assurance: The Uncompromised Standard at YL Machining

To maintain our reputation as industry leaders, quality assurance forms the backbone of our operations. Our commitment to the highest standards integrates the following components:

Rigorous Inspections

Every batch of components is subjected to meticulous quality control protocols, including dimensional inspections utilizing CMM (Coordinate Measuring Machine) technology.

Certification and Compliance

We ensure adherence to industry standards and regulations, providing clients with compliant products that match their operational demands.

Industries We Serve: A Spectrum of Applications

At YL Machining, our expertise spans various sectors, showcasing the potential and flexibility of custom CNC machining:

Aerospace

Precision components are crucial in aerospace applications where safety and reliability are non-negotiable.

Medical

Medical device manufacturing demands high-quality parts that meet rigorous standards, and custom CNC machining excels in this area.

Automotive

Innovations in automotive components rely on the precision and efficiency offered by custom machining solutions.

Robotics

Our specialized machining capabilities support the intricate needs of robotics, enhancing functionality in modern automation systems.

The Future of Custom CNC Machining at YL Machining

As we stand at the brink of Industry 4.0, technology continues to reshape the landscape of custom machining. At YL Machining, we are committed to embracing advancements—including IoT, AI, and machine learning—to enhance our capabilities further. These innovations will streamline processes, empowering us to deliver unmatched quality and efficiency to our clients.

: Your Partner in Precision Engineering

Custom CNC machining offers a world of possibilities for the metal fabrication industry, and at YL Machining, we are proud to be at the forefront of this revolution. Our dedication to quality, precision, and customization positions us as a trusted partner for all your machining needs.

As you contemplate your next project, remember that the fusion of technology and craftsmanship—embodied by custom CNC machining—holds the key to unlocking your vision. Let’s embark on this journey together, transforming your ideas into tangible realities.

—