:

Did you know that the global CNC machining market is expected to exceed $100 billion by 2027? This rapid growth isn’t just a statistic; it represents the increasing reliance on precision manufacturing across a multitude of industries such as aerospace, automotive, and electronics. Among the materials that form the backbone of this market, aluminum stands out due to its exceptional properties, including lightweight design, corrosion resistance, and machinability. But what happens when the demand for custom aluminum parts surges? Enter custom CNC machining, a technology that not only streamlines production but also enhances precision to a level that meets the exacting standards of today’s manufacturing landscape.

The Importance of CNC Machining in Producing High-Precision Aluminum Parts

Custom CNC (Computer Numerical Control) machining is revolutionizing how manufacturers approach the production of aluminum components. It offers remarkable precision, flexibility, and efficiency, making it indispensable for organizations looking to push the envelope in manufacturing capabilities. So, how does this technology enhance the production of high-precision aluminum parts? Let’s break it down.

Understanding CNC Machining: A Brief Overview

CNC machining refers to the process of using computers to control machine tools such as drills, lathes, and mills. This technology automates intricate processes that are traditionally performed by human operators, allowing for greater precision and repeatability. In the context of aluminum parts manufacturing, CNC machining provides:

The Custom CNC Machining Process for Aluminum Parts

Step 1: Designing the Part

The journey begins with a detailed design of the desired component. Designers often use CAD (Computer-Aided Design) software to create a 3D model of the part. This design must account for specific tolerances and performance requirements. As an important note, collaborating early with machining specialists can align expectations for manufacturability, which can significantly influence design decisions.

Step 2: CAM Programming

Once the design is finalized, the next step involves converting the CAD drawing into a format that the CNC machine can understand—often through CAM (Computer-Aided Manufacturing) software. This software generates a series of instructions that dictate the machine’s movements and operations during processing. Advanced CAM software also simulates the machining process to identify any potential issues before actual production begins.

Step 3: Selecting Materials

Choosing the right grade of aluminum is critical to achieving the desired properties in the final product. Popular alloys for CNC machining include 6061, 6063, and 7075, each offering unique qualities such as weldability, corrosion resistance, or enhanced strength. The right material choice affects everything from tooling requirements to the final product’s functionality.

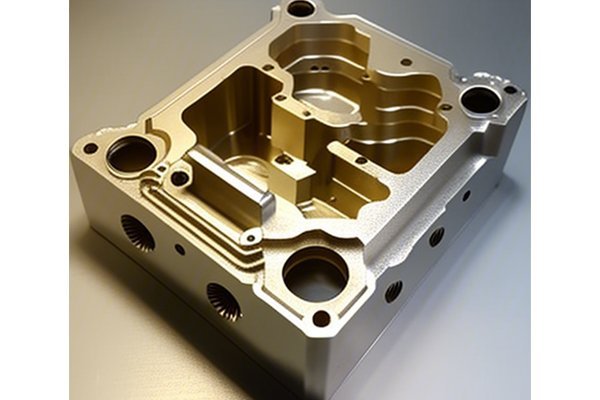

Step 4: Machining the Parts

Once everything is set, the CNC machining process begins. The program dictates the tool paths and operations—whether milling, turning, or drilling. The precision of CNC machining ensures that the intricacies of each design are faithfully replicated.

Key Operations in CNC Machining for Aluminum:

Step 5: Finishing

After machining, parts often require finishing processes such as deburring, anodizing, or polishing. Anodizing is particularly important for aluminum as it enhances corrosion resistance and allows for improved aesthetics through color options without sacrificing the integrity of the part.

Advantages of Custom CNC Machining for Aluminum Parts

Challenges in Custom CNC Machining

While the advantages are substantial, challenges still exist. These include:

Future Trends in Custom CNC Machining

As technology evolves, CNC machining for aluminum parts is set to become even more advanced. Some emerging trends include:

Custom CNC machining has established itself as a vital process in the manufacturing of high-precision aluminum parts. By combining speed with exceptional quality, this technology addresses the evolving demands of modern industries. Whether you are a manufacturer seeking efficiency, an engineer in need of prototypes, or a designer pushing the limits of innovation, CNC machining empowers you to achieve your vision.

Remember, the value of CNC machining extends beyond just producing parts; it represents the future of manufacturing efficiency, precision, and sustainability. As you contemplate your production processes, consider how embracing custom CNC machining could not only enhance your output but also position your organization at the forefront of industrial innovation.

Why This Blog Matters

In today’s rapidly advancing manufacturing world, understanding the capabilities and benefits of custom CNC machining isn’t just advantageous; it’s essential. As we’ve explored, the technology enables the production of rigorous, high-quality aluminum components, ultimately influencing the efficiency and success of various industries. For engineers, designers, and businesses aiming to innovate, gaining this knowledge holds the power to transform your approach to manufacturing in the age of precision engineering. So, keep these insights in mind—your next project could reshape your business potential.