Opening

Did you know that 70% of purchasing experiences are based on how the customer feels they are being treated? In today’s competitive manufacturing landscape, capturing not just business but also the loyalty of customers has never been more crucial. This seems particularly true in the world of CNC (Computer Numerical Control) machining and prototyping. While the technology behind CNC machining is impressive, the applications of strong customer relationship management (CRM) can significantly enhance service quality, leading to higher satisfaction and customer retention. But how can CNC prototypes be strategically aligned with CRM principles to elevate service quality? This blog will delve deeply into actionable strategies to leverage CNC prototyping and effective CRM, aiming to boost service quality to new heights.

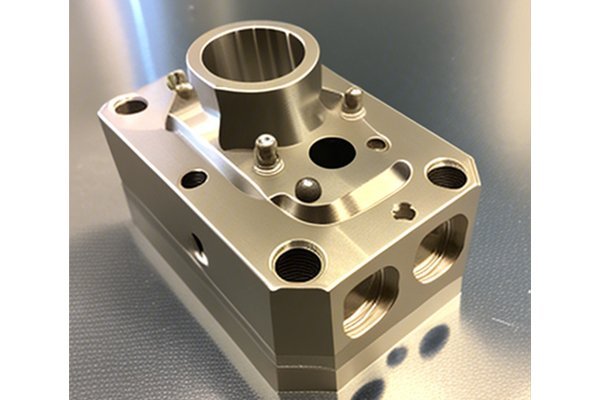

Understanding CNC Prototyping and Its Importance in Manufacturing

CNC prototyping is a digital fabrication process that allows manufacturers to create precise parts and prototypes from a variety of materials. It’s invaluable in various industries, including automotive, aerospace, medical, and consumer goods. The benefits of CNC prototyping include rapid turnaround times, high precision, and the ability to test designs before full production, minimizing the risks associated with new product launches.

The Role of Customer Relationship Management in CNC Prototyping

At its core, CRM involves managing interactions with potential and existing customers to improve service relationships and ultimately drive sales growth. When integrating CRM into CNC prototyping, several factors come into play:

How CNC Prototypes Improve Service Quality Through CRM

Understanding the customer’s requirements, industry standards, and constraints allows manufacturers to produce customized prototypes that are precisely what the customer is looking for. For instance, when working with a client in the medical industry, manufacturers can ensure that prototypes meet stringent health regulations. CRM tools can facilitate this by tracking specifications and requirements throughout the development cycle.

Effective communication lies at the heart of excellent service quality. CNC machining companies that employ CRM systems can seamlessly keep clients informed. Updates regarding the production status of prototypes, potential delays, or design modifications can be conveyed quickly and transparently. This openness creates a more satisfying customer experience as trust is built between the business and the client.

Feedback is perhaps the most crucial component of customer experience enhancement. Implementing a CRM system that allows for structured feedback—from initial inquiries to post-project evaluations—enables manufacturers to gauge client satisfaction and adjust their practices accordingly. For example, if clients express concerns about the dimensional accuracy of prototypes, CNC shops can refine their machining processes and invest in technical training.

Data analytics is a significant element in CRM systems that can lead to refined CNC processes. By analyzing past projects, industries, and customer feedback, manufacturers can identify trends and areas for improvement. For example, if data indicates recurring issues with specific materials, a manufacturer can explore alternative resources or invest in new machinery tailored to that material type.

A solid CRM system can help in efficiently managing resources needed for CNC prototyping. By forecasting customer demands based on historical data, firms can allocate resources such as raw materials, manpower, and machinery more effectively, which ultimately leads to improved service delivery and reduced turnaround times.

Implementing Effective CRM Practices in CNC Prototyping

Achieving synergy between CNC prototyping and CRM requires specific strategies. Here’s how firms can bridge that gap:

Choosing the right CRM software is vital for effective communication and data management. An integrated system that tracks customer interactions, feedback, and project details facilitates the flow of information.

Employees that are well-trained in using CRM tools can better assist customers and understand their needs. Continuous training allows them to adapt to new technologies and methodologies.

Defining what success looks like in the context of customer service helps keep teams focused. Metrics such as customer satisfaction scores, repeat order rates, and engagement levels can gauge the overall effectiveness of CRM initiatives within CNC prototyping.

Building a culture that prioritizes customer experience across all departments encourages employees to engage with CRM systems meaningfully. From sales to production teams, every member should understand the importance of customer satisfaction and how their role can contribute to it.

Establish channels for collecting customer feedback, such as surveys or focus groups, to understand their experiences and expectations. Importantly, ensure that feedback results in tangible changes and improvements.

Real-World Applications of CRM in CNC Prototyping

To grasp the benefits genuinely, let’s explore some case studies of businesses within CNC machining that have effectively integrated CRM with their prototyping services.

Case Study 1: Rapid Prototyping Inc.

Rapid Prototyping Inc., a leader in the industry, recognized that their customer interactions needed improvement. By implementing a robust CRM system, they were able to streamline communication and tailor services more effectively to each client. The use of automated responses increased client engagement, while their focus on feedback led to a 30% rise in repeat business over two years.

Case Study 2: Precision Fabricators

Precision Fabricators identified recurring complaints about the quality of prototypes. Through CRM analytics, they discovered discrepancies in specific machining processes were causing these issues. By investing in targeted training and revising protocols based on customer feedback, they significantly enhanced their service quality, earning a better reputation and new contracts.

The intersection between CNC prototyping and effective customer relationship management is a key area that can revolutionize service quality in the manufacturing sector. By tailoring services, fostering open communication, and utilizing feedback, manufacturers can build deeper relationships with their clients, ultimately leading to higher satisfaction rates and exceptional business growth.

The importance of integrating CRM into CNC prototyping shouldn’t be underestimated. In today’s competitive environment, focusing on customer experience through innovative technologies is not just a strategy; it’s a necessity. As more businesses recognize the power of CRM in enhancing service quality, it becomes clear that those that adapt will lead the industry into the future.

Thank you for taking the time to explore this topic. Reflect on how your practices can evolve and remember, investing in effective CRM solutions isn’t just an option—it’s a branded promise to your customers.

—