: The New Normal in Manufacturing

Did you know that nearly 70% of manufacturers surveyed reported that frequent design changes significantly impact their production timelines? In today’s rapidly evolving market, the ability to adapt quickly to design modifications has become essential for staying competitive. As customer demands shift and technological advancements emerge, the challenge of accommodating these fluctuations is more relevant than ever, particularly in CNC machining.

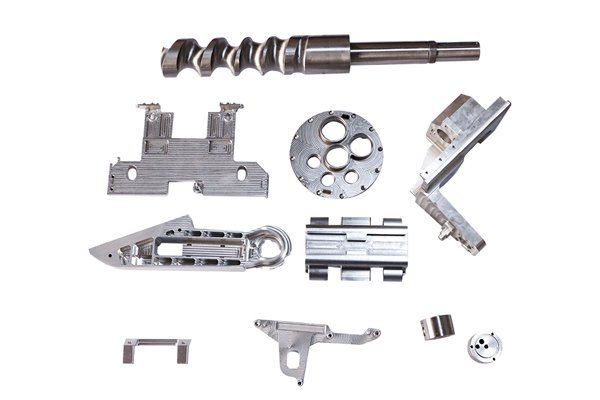

CNC (Computer Numerical Control) machining plays a vital role in modern manufacturing, enabling precision and efficiency in producing parts from various materials. However, the propensity for design alterations can disrupt workflows, increase costs, and lead to delays. This blog will delve into effective strategies for managing frequent design changes within CNC machining processes, ensuring minimal disruption while maintaining quality and precision.

Understanding the Impact of Design Changes

Before crafting solutions, it’s crucial to understand the implications of frequent design changes in CNC machining. Design changes can occur at any point in the development cycle, whether in response to customer feedback, new regulatory requirements, or innovations in technology.

Embracing these design changes proactively is crucial, and it begins with an integrated approach.

Strategies for Managing Frequent Design Changes

Flexibility is paramount when coping with design changes. Companies should invest in adaptable CNC machining equipment capable of handling various processes. Collaborative robots (cobots) can also enhance flexibility on the production floor, providing the ability to switch between tasks seamlessly.

Examples of Flexible CNC Solutions:

Adopting agile methodologies can significantly benefit manufacturers aiming to adapt to frequent design modifications. Agile project management emphasizes collaboration, flexibility, and customer feedback to facilitate quick adaptations in production.

Key Components of Agile Manufacturing:

Software plays a crucial role in managing the complexity of CNC machining. Invest in advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software that can automatically update machining parameters based on design alterations.

Software Features to Seek:

Frequent design changes require clear communication among all stakeholders involved in the manufacturing process. Integrating communication tools can streamline information flow and keep everyone aligned.

Techniques for Enhancing Communication:

Continuous improvement methodologies, such as Lean or Six Sigma, can help eliminate waste and inefficiencies in CNC machining processes impacted by design changes.

Implementation Steps:

The supply chain can significantly influence the success of adapting to design changes. Establishing strong relationships with suppliers can allow for quicker modifications in material supply to match new design requirements.

Supply Chain Strategies:

Quality assurance must remain a priority even when design changes are frequent. Integrating inspection checkpoints during the production process can prevent defects and ensure quality standards are upheld.

Quality Control Methods:

Investing in workforce training enhances a team’s ability to adapt to constant changes. Continuous education around new machining technologies and processes keeps employees skilled and agile.

Training Approaches:

: Adapting to Thrive

As we navigate an era characterised by rapid design changes, manufacturers must adopt a proactive approach to succeed. By investing in flexible technologies, embracing agile practices, fostering robust communication, and committing to continuous improvement, businesses can turn the challenge of frequent design changes into an opportunity for innovation and growth.

In summary, this blog highlights the importance of adopting specific strategies to manage frequent design changes in CNC machining, enabling manufacturers to maintain quality and efficiency in their production processes. As the landscape of manufacturing evolves, honing the ability to adapt to change will become critical; thus, investing in these strategies is not just beneficial but necessary.

Think of the implications: optimizing your CNC machining processes not only helps you remain competitive—it’s also a pathway to exceeding customer expectations. As you consider these methodologies, reflect on how they could transform your production capabilities and elevate your business in the market. The future is agile; it’s time to embrace the change.