Opening: The Fascinating Role of CNC Machining in Modern Manufacturing

Did you know that CNC machining has drastically transformed the plastics industry, enabling manufacturers to create complex and precise components that were once deemed impossible? According to a study by Grand View Research, the global CNC machining market is projected to reach USD 118.2 billion by 2027, with the plastics sector being a significant contributor to this growth. With advancements in technology, achieving a high-quality surface finish in plastic materials has become essential for enhancing product performance, aesthetics, and market competitiveness.

In this blog, we delve deep into the multifaceted approach needed to achieve exceptional surface finishes in CNC machined plastic components. We will explore various techniques, tooling options, and best practices, providing a comprehensive guide for manufacturers looking to elevate their CNC machining capabilities.

Understanding Plastic Materials in CNC Machining

Before diving into the methods for achieving a high-quality surface finish, it’s crucial to understand the characteristics of the plastic materials commonly used in CNC machining. Generally, plastics can be categorized into two primary types: thermoplastics and thermosetting plastics.

Knowing the properties of the selected plastic material helps determine the best machining parameters and surface finishing techniques.

Key Factors Affecting Surface Finish

Achieving a high-quality surface finish in CNC machined plastics hinges on several key factors:

Different plastic materials have varying machining characteristics that affect the surface finish. For instance, softer plastics tend to produce smoother finishes compared to harder ones. It’s essential to choose a material with high machinability for the desired application.

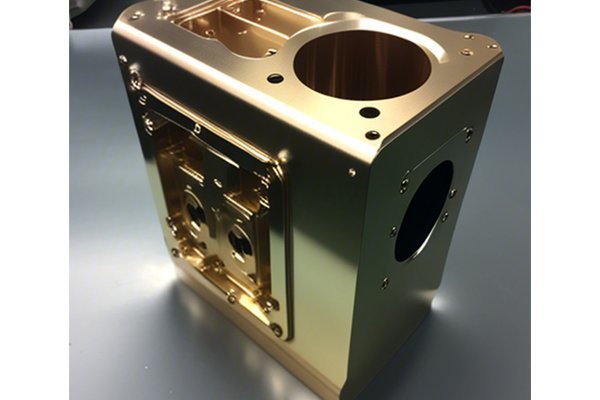

Cutting tools play a decisive role in the quality of the surface finish. The selection of tool material, geometry, and coating can significantly affect the machining process. High-speed steel (HSS), carbide, and coated tools (such as TiN or TiAlN) are common choices for plastic machining.

Parameters such as spindle speed, feed rate, and depth of cut can dramatically influence the surface finish. A higher spindle speed generally leads to a smoother finish, while a slower feed rate allows for greater accuracy and detail.

Maintaining optimal temperature during machining is crucial in preventing thermal deformation of plastics. Using coolant or specialized lubricants can help dissipate heat and improve surface quality.

After machining, several post-processing techniques can improve the surface finish of plastic components. These include sanding, polishing, bead blasting, and chemical smoothing.

Techniques to Achieve High-Quality Surface Finish

Now that we’ve covered the factors affecting surface finish, let’s explore some effective techniques for achieving a high-quality finish in CNC machined plastic parts.

Choosing the right tool geometry is vital for minimizing burr formation and achieving smooth cuts. Tools with sharp edges and specialized designs, such as razor-sharp end mills or single-flute cutters, are advantageous when machining soft plastics. For harder plastics, using tools with a larger rake angle can help reduce cutting forces and enhance surface smoothness.

Carefully adjusting your machining parameters is crucial. A systematic approach can yield impressive results:

Utilizing the correct cooling strategy can help maintain temperature control, preventing deformation and ensuring a high-quality surface finish.

Following CNC machining, the use of post-processing techniques can elevate the surface finish from good to exceptional.

Quality Control Considerations

Achieving high-quality surface finishes in CNC machined plastics isn’t a one-time adjustment; it requires continuous quality control. Regular inspection of machined components is essential to ensure conformance to specifications:

: The Path to Excellence in CNC Machining for Plastics

In summary, achieving a high-quality surface finish in CNC machined plastic materials is a multifaceted process that requires a deep understanding of the materials, tools, parameters, and post-processing techniques. By focusing on optimizing cutting tools, fine-tuning machining parameters, managing temperatures effectively, and employing proper post-processing methods, manufacturers can significantly enhance their plastic parts’ surface finish.

As the demand for precision and aesthetic qualities continues to grow across various industries, the importance of mastering these CNC machining techniques cannot be overstated. A commitment to higher standards of surface finish not only impacts product performance but also positions manufacturers to remain competitive in a rapidly evolving market.

The considerations and technologies discussed here are fundamental to leveraging CNC machining effectively in the plastics industry. Your exploration into optimizing surface finishes will not only lead to immediate benefits for your production processes but will also pave the way for long-term success in your manufacturing endeavors. Keep this guide in mind as a resource to navigate the intricacies of plastic machining, ensuring that every part produced meets the excellence the market now demands.