In the fast-paced world of manufacturing, finding the right CNC machining service provider is crucial for the success of any project. The quality of the parts, the efficiency of the service, and the reliability of the provider can significantly impact the overall outcome of your production processes. At YL Machining, we understand the challenges that companies face when searching for CNC machining services, and we are committed to providing top-notch solutions tailored to meet our clients’ specific needs.

The Importance of Choosing the Right CNC Machining Service

As industries evolve, the demand for high-precision components increases. CNC (Computer Numerical Control) machining has become an essential process for producing intricate and precise parts used in various applications, including automotive, aerospace, medical devices, and electronics. Selecting a CNC machining service provider involves more than just comparing prices; it requires a thorough evaluation of several factors to ensure that the chosen partner can deliver high-quality results consistently.

What YL Machining Offers

YL Machining is a leading provider of CNC machining services specializing in the production of high-precision components. Our comprehensive service offerings include:

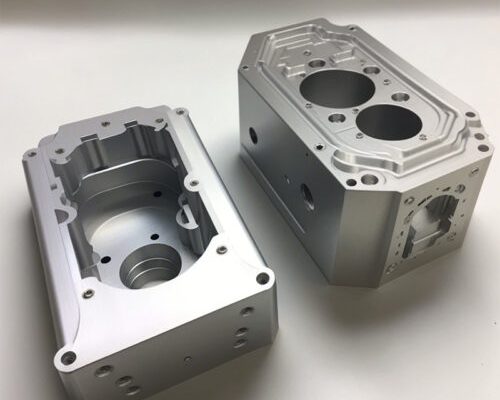

- CNC Milling and Turning: We utilize advanced CNC milling and turning technologies to produce intricate parts with tight tolerances and complex geometries.

- Material Expertise: We work with a wide variety of materials, including aluminum, stainless steel, titanium, and plastics, ensuring that we can meet diverse customer requirements.

- Custom Prototyping: Our rapid prototyping services allow clients to validate their designs before full-scale production, saving time and costs.

- Finishing Services: We offer a range of finishing options, including anodizing, plating, and polishing, to enhance the aesthetics and functionality of machined parts.

- Quality Assurance: Our rigorous quality control processes ensure that every component meets the highest standards of precision and reliability.

Key Considerations When Searching for CNC Machining Services

When searching for a CNC machining service provider, several key factors warrant attention. At YL Machining, we recognize the importance of these considerations and strive to address them effectively:

1. Quality of Work

One of the most critical factors in choosing a CNC machining service is the quality of work. It is essential to review the provider’s previous projects and customer testimonials to assess their ability to deliver high-quality parts. At YL Machining, we take pride in our commitment to quality. Our team employs advanced quality control measures throughout the manufacturing process to ensure that every part meets stringent specifications.

2. Experience and Expertise

Experience matters in the CNC machining industry. An established provider with a track record of successful projects is more likely to understand the complexities of various machining processes and materials. At YL Machining, our skilled technicians have years of experience in the industry, enabling us to handle a wide range of machining challenges effectively.

3. Technology and Equipment

The technology and equipment used by a CNC machining service provider play a significant role in determining the precision and efficiency of the manufacturing process. It is essential to choose a provider that invests in state-of-the-art CNC machines and software. YL Machining utilizes the latest CNC technology to ensure that we can produce high-precision parts with exceptional accuracy and efficiency.

4. Lead Times and Production Capacity

Understanding the lead times and production capacity of a CNC machining service provider is crucial for project planning. Delays in production can lead to increased costs and missed deadlines. At YL Machining, we prioritize efficient production scheduling and have the capacity to handle both small and large-scale projects. We work closely with our clients to provide realistic timelines and ensure timely delivery.

5. Customization Options

Many projects require custom solutions tailored to specific needs. It is essential to choose a CNC machining service provider that offers a range of customization options. At YL Machining, we specialize in custom machining services, allowing us to produce parts according to our clients’ unique specifications. Our flexibility ensures that we can accommodate a wide variety of designs and requirements.

6. Communication and Support

Effective communication is vital in any manufacturing partnership. A CNC machining service provider should be responsive and proactive in addressing client inquiries and concerns. At YL Machining, we pride ourselves on our customer support. Our dedicated team is always available to provide updates, answer questions, and ensure that our clients are informed throughout the machining process.

7. Pricing Structure

While price should not be the sole determining factor, it is essential to understand the pricing structure of potential CNC machining service providers. Transparent pricing helps clients make informed decisions and avoid unexpected costs. At YL Machining, we provide clear and competitive pricing for our services, ensuring that clients understand the value they receive for their investment.

8. Certifications and Compliance

For many industries, compliance with specific standards and regulations is crucial. It is important to verify that a CNC machining service provider holds the necessary certifications and adheres to industry standards. YL Machining is committed to maintaining high-quality standards and complies with relevant regulations to ensure that our clients receive safe and reliable products.

9. Client Reviews and Testimonials

Before making a final decision, potential clients should seek out reviews and testimonials from previous customers. Positive feedback can provide valuable insights into a CNC machining service provider’s reliability, quality, and customer service. At YL Machining, we encourage potential clients to review our testimonials and case studies to gain confidence in our capabilities.

Why Choose YL Machining?

Choosing YL Machining as your CNC machining service provider comes with numerous benefits. We understand the complexities involved in manufacturing precision components, and we are dedicated to delivering exceptional results. Here are several reasons why you should consider partnering with us:

- Uncompromising Quality: We prioritize quality in every aspect of our operations. Our rigorous quality control processes ensure that each component meets the highest standards of precision and reliability.

- Experienced Team: Our skilled technicians bring years of experience to the table, allowing us to tackle complex machining challenges effectively.

- Advanced Technology: We invest in the latest CNC technology and equipment to ensure that we can deliver high-precision parts efficiently.

- Custom Solutions: Our commitment to customization allows us to produce parts tailored to your specific needs, ensuring that your requirements are met.

- Timely Delivery: We understand the importance of meeting deadlines and work diligently to ensure that your projects are completed on time.

- Exceptional Customer Support: Our dedicated team is always available to assist you, providing clear communication and support throughout the machining process.

- Transparent Pricing: We offer competitive and transparent pricing, allowing you to understand the value of our services without unexpected costs.

- Commitment to Improvement: At YL Machining, we are always seeking ways to enhance our processes and services. We value customer feedback and use it to drive continuous improvement.

Common Questions About CNC Machining Services

As a trusted CNC machining provider, we frequently receive questions related to our services and processes. Here are some common inquiries and their answers:

1. What types of materials can you machine?

We work with a wide range of materials, including metals like aluminum, stainless steel, titanium, and various plastics. Our team can guide you in selecting the best material for your project.

2. Can you handle custom designs?

Yes, we specialize in custom CNC machining services and can produce parts according to your unique specifications.

3. What is your typical lead time for projects?

Lead times vary depending on the complexity and size of the project. We work closely with clients to establish realistic timelines and ensure timely delivery.

4. How do you ensure quality control?

We implement rigorous quality control measures throughout the machining process, including inspections and testing, to ensure that every part meets our high standards.

5. How can I get a quote for my project?

You can request a quote by contacting us directly through our website, email, or phone. Our team will gather the necessary details and provide you with a competitive quote.

Conclusion

Finding the right CNC machining service provider is a critical step in ensuring the success of your manufacturing projects. At YL Machining, we understand the challenges you face and are committed to providing exceptional solutions tailored to your specific needs. Our dedication to quality, advanced technology, and customer support sets us apart in the industry.

When you choose YL Machining, you gain a trusted partner that prioritizes your success. We look forward to collaborating with you on your next project and helping you achieve your manufacturing goals. Contact us today to learn more about our CNC machining services and how we can assist you in realizing your vision. Together, we can create precision components that meet the highest standards of quality and performance.