1. Choosing the Right Aluminum Alloy for Your Enclosure

Selecting the appropriate aluminum alloy is the first critical decision when machining a keyboard enclosure. Not all alloys are created equal, and the alloy you choose will impact the strength, durability, and finish of the final product. Two of the most popular choices for CNC machining aluminum enclosures are 6061 and 6063.

- 6061 Aluminum is known for its excellent strength-to-weight ratio, which makes it an ideal choice for custom enclosures. It’s commonly used in high-performance applications, such as aerospace and automotive parts. If you need a durable, long-lasting aluminum keyboard enclosure that can withstand regular wear and tear, 6061 is a great option.

- 6063 Aluminum, on the other hand, is softer and often preferred for designs that emphasize appearance over strength. This alloy is more commonly used for decorative purposes, offering a smoother, polished finish that works well with anodizing processes.

The choice of alloy will also impact the machining process itself, so make sure to discuss your project’s requirements with your CNC supplier to choose the best material for your needs.

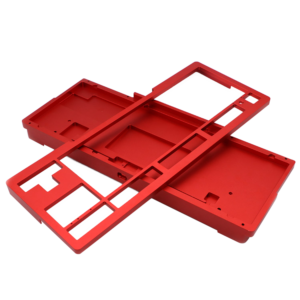

2. Precision CNC Machining: Achieving the Perfect Fit

One of the biggest advantages of CNC machining is its ability to deliver high precision. When it comes to custom aluminum keyboard enclosures, this precision ensures that all parts fit together perfectly, with no issues related to alignment, gaps, or dimensional inaccuracies.

It’s important to be clear about your design’s tolerances—this refers to the permissible limits of variation in your design’s dimensions. CNC machines are capable of working with extremely tight tolerances, so it’s essential that your design specifications account for the precise measurements needed for components like the PCB (printed circuit board) and key switches. A few thousandths of an inch can make the difference between a perfect fit and a problematic assembly.

3. Surface Finishing: Ensuring Both Functionality and Aesthetics

After CNC machining, your aluminum keyboard enclosure will require a finish to protect it from environmental factors such as oxidation, scratches, and wear. The finish you choose can also dramatically enhance the appearance of the enclosure.

- Anodizing: This process forms a protective oxide layer on the aluminum, providing enhanced durability and corrosion resistance. Anodizing also allows for a variety of colors, giving your custom keyboard enclosure a unique look.

- Bead Blasting: This treatment creates a matte finish with a slightly textured surface, which can enhance both grip and appearance, giving your enclosure a professional, industrial look.

- Polishing/Brushing: If you’re looking for a sleek, glossy appearance, polishing or brushing can achieve a reflective, smooth surface that gives your keyboard enclosure a high-end finish.

Selecting the right surface finish is essential not only for the visual appeal but also for the long-term performance of the enclosure. You want a finish that will resist scratches and wear, especially if the keyboard is to be used regularly.

4. Ensuring High-Quality Control: Avoiding Defects in Your Enclosure

No matter how well-designed your keyboard enclosure is, defects during machining or finishing can ruin the whole project. A common issue that arises is surface imperfections, such as scratches or dents, which may occur during machining or handling. Additionally, dimensional inconsistencies could cause problems with assembly, making it essential to maintain a strict quality control process.

Make sure to request that your CNC manufacturer perform thorough inspections at each stage of the production process to ensure the quality of the enclosure. Quality checks should include:

- Visual inspection: To spot any surface defects.

- Dimensional verification: To make sure the design tolerances are met.

- Functional testing: To ensure that the parts fit together correctly and that the enclosure accommodates all components.

Having these checks in place will help you avoid costly mistakes and ensure that the final product meets your expectations.

5. Time Management: Managing Deadlines and Lead Times

As with any custom CNC machining project, managing timelines is crucial. CNC machining can sometimes take longer than anticipated, especially if your design is intricate or requires additional treatments. When planning your project, be sure to account for:

- Design review and adjustments: These stages can take time as you finalize the design.

- Machining: Depending on complexity, CNC machining can take a few days to several weeks.

- Post-machining processes: If your design requires additional treatments like anodizing or bead blasting, those processes can add more time.

Clear communication with your CNC manufacturer about lead times and delivery schedules is essential. They should be able to provide a detailed production timeline so that you can plan your project accordingly.

6. After-Sales Support: Ensuring Ongoing Satisfaction

Once your custom CNC machined aluminum keyboard enclosure is ready, you might encounter post-production issues such as fitment or finish concerns. Having reliable after-sales support from your CNC manufacturer is essential to resolve any issues that might arise after the project’s completion.

Before committing to a CNC machining provider, inquire about their warranty or post-production support. Will they assist with any necessary adjustments or refinements? A trustworthy CNC manufacturer should be committed to customer satisfaction and be available to resolve issues that may arise after delivery.

7. Cost Considerations: Balancing Quality and Budget

Custom CNC machining of aluminum keyboard enclosures can be an investment, and balancing your budget with your quality requirements is crucial. Factors such as the complexity of your design, the choice of material, surface treatments, and lead time will all influence the cost.

While it’s tempting to go with the cheapest option, keep in mind that cutting corners may lead to issues with quality, fitment, or durability. Work with a reputable CNC manufacturer who can offer a fair price while maintaining the quality you expect. It’s important to get a quote based on your exact specifications and discuss any potential cost-saving measures that could help you stay within budget without sacrificing quality.

Conclusion: Bringing Your Custom CNC Aluminum Keyboard Enclosure to Life

Designing and manufacturing a custom CNC machined aluminum keyboard enclosure is no small feat, but with the right planning and considerations, you can create a product that is both aesthetically pleasing and highly functional. From selecting the right alloy and ensuring precise machining to finishing the product with care and ensuring ongoing quality control, every step in the process matters.

By following these key considerations and working closely with your CNC machining partner, you’ll be on the path to producing an enclosure that stands out in both performance and design. Don’t forget to carefully manage timelines, costs, and after-sales support to ensure the best outcome for your project.

Do you have experience with CNC machining for custom enclosures or keyboards? I’d love to hear about your process and challenges in the comments below!