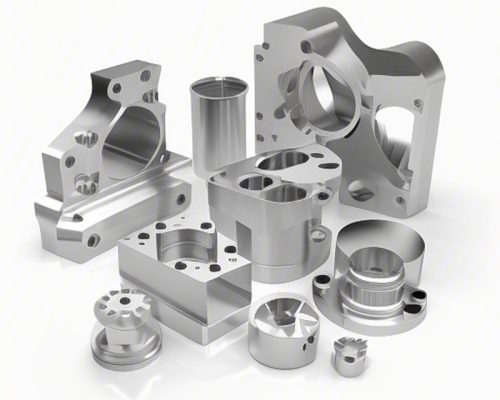

In the fast-paced and highly competitive field of CNC machining, precision is not merely a goal; it is a fundamental requirement. At YL Machining, we understand that our clients depend on the accuracy and reliability of the components we produce. Precision inspection reports play a crucial role in ensuring that our machined parts meet the exact specifications and standards required by various industries. This article delves into the significance of precision inspection reports and how YL Machining guarantees the quality of every component we manufacture.

The Significance of Precision Inspection Reports

Precision inspection reports serve multiple important functions in the machining process. These reports are not just documentation; they provide vital information that reinforces trust between YL Machining and our clients. Here are several key reasons why these reports matter:

- Quality Assurance: Precision inspection reports confirm that the machined parts meet the stringent quality standards expected by our clients. These reports provide measurable evidence of compliance with specifications, ensuring that every part performs as intended in its application.

- Regulatory Compliance: Many industries, particularly aerospace, automotive, and medical, require adherence to strict regulations and standards. By providing precision inspection reports, YL Machining helps clients demonstrate compliance with industry requirements, minimizing risks and liabilities.

- Client Confidence: Transparency is vital in building lasting relationships with our clients. Precision inspection reports provide the necessary documentation that reinforces confidence in our manufacturing processes and capabilities. Clients can trust that their parts are produced with the utmost precision and care.

- Facilitating Problem Resolution: In the rare event that a part does not meet specifications, precision inspection reports allow for swift identification and resolution of the issue. These reports provide a clear reference point, making it easier to determine where the problem occurred and how to rectify it.

YL Machining’s Precision Measurement Process

At YL Machining, we take pride in our meticulous approach to precision measurement and inspection. Our process is designed to ensure that every component we produce adheres to the highest standards of quality and accuracy. Here is how we accomplish this:

- Advanced CNC Machinery: We utilize state-of-the-art CNC machining equipment capable of producing complex geometries with high precision. Our machines are regularly calibrated to maintain optimal performance and accuracy throughout the production process.

- Skilled Technicians: Our team comprises highly skilled technicians who possess extensive experience in CNC machining. They are trained in the latest techniques and technologies, enabling them to produce parts that meet or exceed client expectations.

- In-Process Inspections: Throughout the machining process, we conduct in-process inspections to monitor the accuracy of the components being produced. This proactive approach allows us to identify potential issues early, ensuring that any necessary adjustments are made promptly.

- Final Inspection and Measurement: After machining is complete, each part undergoes a thorough final inspection. Our quality control team employs advanced measuring instruments, such as coordinate measuring machines (CMMs) and optical comparators, to verify the dimensions and tolerances of the finished components.

- Documentation of Results: Following the final inspection, we compile a precision inspection report that details the measurements taken, the specifications met, and any deviations identified. This report serves as a comprehensive record of the quality of the parts produced.

How We Address Client Concerns

At YL Machining, we recognize that our clients may have specific concerns regarding precision and quality. Our precision inspection reports address these concerns in several ways:

- Detailed Reporting: Each precision inspection report includes comprehensive details about the measurements, inspection methods, and compliance with specifications. This level of detail ensures clients have a clear understanding of the quality of their parts.

- Clear Communication: We maintain open lines of communication with our clients throughout the manufacturing process. This includes discussing expectations for precision measurements and addressing any questions or concerns they may have.

- Responsive to Feedback: We value client feedback regarding our precision inspection reports. If a client requests additional information or clarification, we respond promptly to ensure their needs are met.

Comprehensive Solutions Beyond Precision Reports

While precision inspection reports are essential, YL Machining offers a wide range of services to support our clients’ diverse manufacturing needs. Our capabilities extend beyond inspection and quality assurance:

- CNC Machining Services: Our core competency lies in precision CNC machining, allowing us to produce high-quality components across various industries, including aerospace, automotive, and medical.

- Rapid Prototyping: We provide rapid prototyping services that enable clients to quickly develop and test new designs. Our precision measurement capabilities ensure that prototypes are accurate and reliable.

- 3D Printing Solutions: Our advanced 3D printing services offer flexibility and innovation for clients looking to produce complex parts. We also provide precision inspection reports for 3D-printed components.

- Injection Molding: For clients needing high-volume production, our injection molding capabilities deliver consistent quality and precision. Each production run is supported by our thorough inspection and reporting processes.

- Assembly Services: We offer assembly services for clients looking to integrate multiple components into finished products. Our quality assurance process ensures that every assembled unit meets strict quality standards.

- Surface Treatment Options: To enhance the durability and performance of machined parts, we provide various surface treatment options, including anodizing, plating, and powder coating.

- Expert Consultation: Our team of experts is available to provide consultation on design, materials, and manufacturing processes. We work closely with clients to optimize their projects for quality and efficiency.

Continuous Improvement and Client Satisfaction

At YL Machining, we are committed to continuous improvement. Our precision inspection process is just one aspect of our overall quality assurance system, which is designed to adapt and evolve based on client feedback and industry trends. Here’s how we ensure ongoing client satisfaction:

- Regular Training and Development: We invest in the training and development of our workforce, ensuring they stay current with the latest industry practices and technologies. This commitment to professional growth enhances our overall machining capabilities.

- Feedback Integration: We actively solicit feedback from our clients regarding our precision inspection reports and overall service quality. This information is invaluable for identifying areas for improvement and implementing necessary changes.

- Technology Upgrades: We continuously evaluate and upgrade our machinery and inspection tools to ensure we are utilizing the latest technologies available. This proactive approach allows us to maintain our competitive edge in the market.

- Client-Centric Approach: Our commitment to client satisfaction drives every aspect of our operations. We prioritize understanding our clients’ unique needs and expectations, tailoring our services accordingly.

At YL Machining, precision inspection reports are integral to our commitment to quality and customer satisfaction. By ensuring that every component we produce meets the highest standards of accuracy, we provide our clients with the confidence they need to proceed with their projects.

Our advanced machinery, skilled workforce, and comprehensive quality control processes enable us to deliver exceptional results consistently. If you are looking for a machining partner that prioritizes precision and quality, YL Machining is here to support your needs. Contact us today to learn more about our services and how we can assist you in achieving your manufacturing goals with precision inspection reports and more. Together, we can create a successful partnership based on quality, trust, and excellence in every project.