At YL Machining, we understand that CNC machining projects are complex, requiring precision, expertise, and a well-organized approach to ensure success. Whether it’s a prototype or a large-scale production run, the outcome of your CNC machining project depends on several factors that must be carefully managed from start to finish. In this guide, we will walk you through key considerations that can help ensure the success of your CNC machining project, and how YL Machining is uniquely equipped to deliver outstanding results.

Why Proper Planning is Critical for CNC Machining Projects

When CNC machining projects are not adequately planned or managed, it can result in delayed timelines, higher costs, or parts that do not meet required specifications. Such outcomes can be costly and frustrating for any business. Ensuring the success of your CNC project means paying attention to every step, from the initial design phase to the final production and delivery. With our experience, YL Machining is dedicated to helping customers avoid common pitfalls and achieve top-quality results.

Some of the key risks of poor planning include:

- Production Delays: Unforeseen issues such as material shortages, incorrect tolerances, or unforeseen machine downtime can lead to costly delays.

- Design Flaws: Without careful review and collaboration, designs might contain features that are difficult or impossible to machine, leading to errors or costly redesigns.

- Cost Overruns: Inefficient material use, excessive setup times, and rework due to errors can quickly drive up project costs.

- Inconsistent Quality: Poor attention to detail during the machining process can result in parts that do not meet the required specifications or standards.

How YL Machining Ensures the Success of Your CNC Project

At YL Machining, we pride ourselves on delivering CNC machined parts that meet the highest standards of precision, quality, and timeliness. Here are the key ways we ensure your CNC machining project is a success:

1. Expert Consultation During the Design Phase

Every successful CNC machining project begins with a solid design. At YL Machining, we collaborate closely with our clients during the initial design phase to ensure the project is on the right track from the start. Our experienced team works with you to review CAD drawings, assess material choices, and ensure that the design is optimized for CNC machining.

Design for Manufacturability (DFM) Expertise: We offer DFM consulting to ensure that your design is feasible for CNC machining. By considering factors such as tool access, part orientation, and machining tolerances, we can help you avoid costly design flaws before they arise. This not only saves time but also ensures that your parts can be manufactured efficiently and accurately.

Material Selection Guidance: The choice of material can greatly impact the success of your CNC machining project. YL Machining helps you select the most appropriate materials based on factors like strength, weight, corrosion resistance, and cost. Our experience in machining metals like aluminum, stainless steel, and titanium, as well as engineering plastics, allows us to recommend the best options for your application.

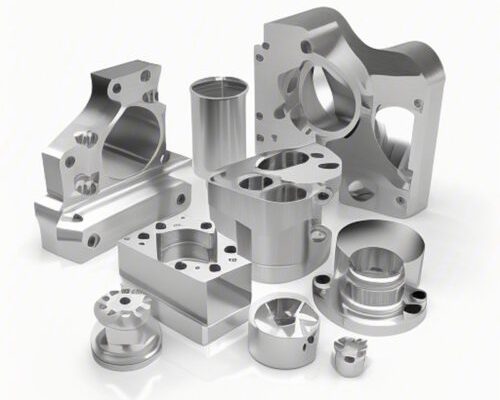

2. Advanced CNC Machining Capabilities

Our state-of-the-art CNC machines provide unparalleled precision and flexibility. Whether your project requires CNC milling, CNC turning, or multi-axis machining, YL Machining has the equipment and expertise to meet the most demanding requirements.

Precision and Accuracy: At YL Machining, we use the latest CNC technology to achieve tight tolerances and high repeatability. Our machines are capable of producing parts with tolerances as tight as ±0.005 mm, ensuring that each component is made exactly to your specifications. This level of precision is crucial in industries such as aerospace, medical devices, and automotive manufacturing, where even the smallest deviations can lead to performance issues.

Efficiency and Speed: Our CNC machines are optimized for both speed and precision, meaning that we can produce parts quickly without sacrificing quality. This allows us to meet tight deadlines, even for complex or high-volume projects. Our experience in optimizing machining processes means that we can keep cycle times short, reducing costs and lead times for our clients.

3. Quality Control and Inspection

Quality control is at the heart of everything we do at YL Machining. We understand that even the most precise machining operations need to be backed by thorough inspection and testing to ensure that every part meets the required standards. Our quality assurance processes are designed to catch any potential issues before they leave our facility, giving you confidence in the reliability and consistency of your parts.

In-Process Inspection: We perform inspections at key stages of the machining process to catch any issues early. This includes checking dimensions, tolerances, and surface finishes to ensure that everything is within spec.

Final Inspection and Reporting: Before delivery, every part undergoes a final inspection to verify that it meets all client specifications. We also provide detailed inspection reports upon request, so you can have full visibility into the quality of your parts. Our advanced measurement tools, including CMM (Coordinate Measuring Machines), allow us to verify even the most complex geometries with precision.

4. Flexible Solutions for Prototyping and Production

Whether you need a single prototype or thousands of production parts, YL Machining has the flexibility to meet your needs. Our experience in both rapid prototyping and high-volume production ensures that we can scale your project efficiently, regardless of size or complexity.

Rapid Prototyping: For projects that require quick turnaround times, our rapid prototyping services allow you to test and refine designs in a matter of days. Our ability to produce high-quality prototypes quickly means you can move from concept to production faster, reducing time to market.

Scalable Production: Once your design is finalized, we are ready to scale up to full production. Our CNC machining services are equipped to handle high-volume orders while maintaining the same level of quality and precision. This scalability is essential for clients in industries such as electronics, automotive, and aerospace, where large quantities of parts are often required.

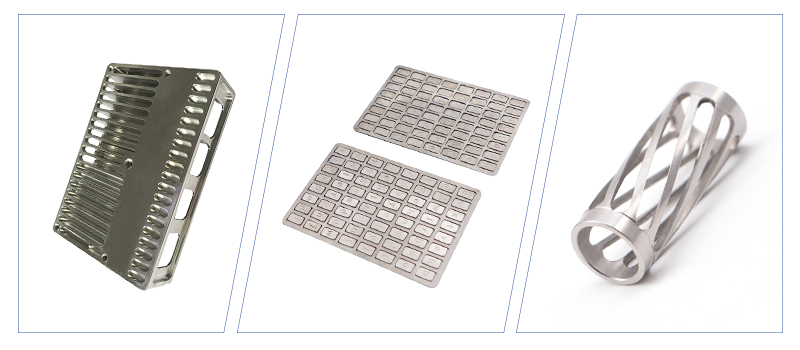

5. Post-Machining Services and Finishing Options

At YL Machining, we go beyond just machining to offer a wide range of post-processing services to enhance the functionality and appearance of your parts. Our finishing services ensure that your parts not only meet dimensional requirements but also have the surface finish and durability required for their application.

Surface Finishing: Depending on your project’s needs, we offer several finishing options, including anodizing, powder coating, polishing, and bead blasting. These services improve the appearance and corrosion resistance of your parts, making them suitable for demanding environments.

Heat Treatment: For applications that require increased strength or wear resistance, we can provide heat treatment services to improve the material properties of your parts. This is especially useful for components that will experience high loads or temperatures.

Assembly and Packaging: If your project involves multiple components, we can provide assembly services to deliver a fully assembled product. We also offer custom packaging solutions to ensure that your parts arrive safely and ready for use.

What YL Machining Can Solve for You

Beyond precision machining, YL Machining addresses several other challenges that can arise in CNC machining projects:

- Tight Lead Times: We are committed to meeting tight deadlines without compromising on quality. Our efficient production processes and in-house expertise allow us to deliver parts on time, even for urgent projects.

- Design Optimization: We help clients optimize their designs for manufacturability, reducing costs and production time while maintaining quality. This is particularly important when transitioning from prototype to full production.

- Complex Geometries: Our advanced CNC machines and skilled machinists allow us to produce complex parts with intricate geometries, including multi-axis milling and turning. This capability is essential for industries like aerospace and medical devices, where precision and complexity are paramount.

Additional Services Offered by YL Machining

In addition to CNC machining, YL Machining offers a comprehensive range of services to support your manufacturing needs:

- CNC Milling and Turning: Our CNC milling and turning services are ideal for producing precision parts with complex geometries. We can machine a wide range of materials, from metals to plastics, to meet the demands of any project.

- Custom Tooling and Fixtures: For clients with unique requirements, we offer custom tooling and fixture design to ensure that your parts are machined with maximum efficiency and precision.

- 3D Printing: For rapid prototyping or producing parts with complex internal geometries, our 3D printing services provide an excellent solution. We can produce prototypes quickly and affordably, allowing you to test designs before committing to full production.

- Laser Cutting and Engraving: Our laser cutting and engraving services provide a precise and efficient way to cut materials and add detailed markings or logos to your parts.

- Supply Chain Management: YL Machining offers supply chain management services to handle the logistics of your project from start to finish. We can source materials, coordinate production, and deliver your parts on time, every time.

At YL Machining, we are committed to helping our clients succeed in their CNC machining projects. By offering expert design consultation, advanced machining capabilities, strict quality control, and a wide range of finishing options, we ensure that every project is completed to the highest standards. Our flexible solutions for prototyping and production, along with our commitment to meeting tight deadlines, make us the ideal partner for all your CNC machining needs.

Contact us today to discuss your next CNC machining project and discover how YL Machining can help you achieve success with precision, efficiency, and quality.