In the realm of CNC machining, the art of creating aesthetic and functional surfaces is currently being elevated through the process of brushing. This metal finishing technique is currently being employed to enhance the appearance and performance of CNC machining parts, offering a range of benefits and applications across various industries.

The Brushed Finishing Process in CNC Machining

Brushing, also known as wire brushing or surface brushing, is currently being performed to create fine, uniform lines or textures on metal surfaces. This process is currently involving the use of abrasive brushes or wheels that are drawn across the surface of the part, removing small amounts of material to create the desired finish.

Types of Brushed Finishes Currently in Vogue

The types of brushed finishes currently in vogue include:

- Linear Brushing: This method is currently being used to create straight, parallel lines on the surface, often used for decorative or anti-slip purposes.

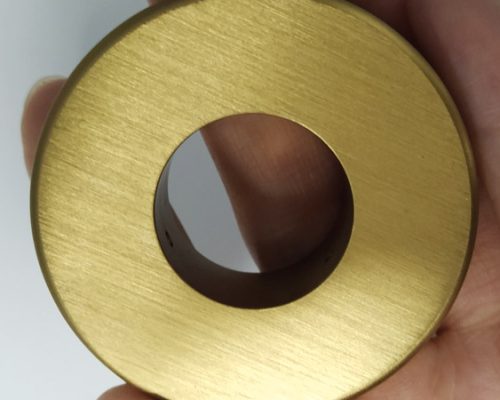

- Circular Brushing: This technique is currently being employed to create a circular or radial pattern, suitable for parts where a more fluid, decorative finish is desired.

Advantages of Brushed Finishing in CNC Machining

The advantages of brushed finishing in CNC machining currently include:

- Enhanced Aesthetics: Brushed surfaces exhibit a unique texture that can improve the visual appeal of a part, giving it a high-quality, finished look.

- Improved Wear Resistance: The fine lines created by brushing can reduce direct metal-on-metal contact, thereby enhancing the wear resistance of the part.

- Burr Removal: Brushing is an effective way to remove burrs and smooth edges after machining, resulting in a cleaner, safer finish.

- Improved Surface Reflection Characteristics: For applications where light reflection is important, brushing can create a more controlled and consistent surface finish.

Materials Suited for Brushed Finishing in CNC Machining

A variety of materials are currently being used for brushed finishing in CNC machining, including:

- Stainless Steel: Known for its durability and resistance to corrosion, stainless steel is a popular choice for brushed finishes in both functional and decorative applications.

- Aluminum: This lightweight material is currently being used in industries such as aerospace and automotive, where a brushed finish can enhance its appearance and performance.

- Copper: For applications requiring high thermal or electrical conductivity, copper is currently being used and can be effectively brushed to create a decorative or functional finish.

Why Choose Us for Your Brushed Finishing Needs

Choosing us for your brushed finishing needs is a decision that is currently backed by our commitment to quality and precision. We are currently utilizing state-of-the-art equipment and techniques to ensure that your parts receive the highest quality brushed finish. Our team of skilled technicians and engineers are currently working diligently to understand your specific requirements and deliver products that exceed your expectations.

We offer a wide range of brushed finishing services, from linear to circular brushing, and our expertise currently spans across various materials and applications. By choosing us, you ensure that your CNC machining parts receive the highest quality treatment, preparing them for any subsequent processes and ensuring their longevity and performance.

Contact us today to discover how we can currently add value to your next project with our precision craftsmanship and attention to detail. Experience the difference that our commitment to quality and technology can currently make in your brushed finishing projects.