When it comes to manufacturing parts for night vision cameras, the stakes are high. These components require precision, durability, and seamless integration to function effectively in challenging environments. As someone deeply immersed in CNC machining, I can confidently say that low-volume CNC customization is a game-changer for producing high-quality night vision camera parts.

At YL-Machining, we specialize in offering CNC machining services tailored for low-volume production, ensuring that each part meets exacting standards. In this article, I’ll share the unique advantages of using CNC machining for night vision camera components, from faster turnarounds to unparalleled quality control.

Why Choose Low-Volume CNC Customization for Night Vision Camera Parts?

Night vision cameras are used in critical applications, including military, security, and surveillance. This means every component must perform flawlessly. However, high-volume manufacturing may not always be practical for specialized designs or prototypes.

Here’s why low-volume CNC machining is the ideal solution:

- Flexibility in design iterations: Quickly refine and perfect prototypes or custom designs.

- Reduced costs: Avoid the expense of large-scale tooling and molds.

- Precision engineering: CNC machines produce tight tolerances essential for sensitive camera systems.

- Material compatibility: Work with a variety of materials to achieve the required performance.

Step-by-Step: Low-Volume CNC Customization Process for Night Vision Camera Parts

1. Understanding Specific Requirements

The first step in producing night vision camera components is gaining a clear understanding of the project’s goals. This involves close collaboration with clients to define:

- Critical tolerances: Ensuring parts fit precisely with optical or electronic systems.

- Environmental conditions: Designing for durability in low-light, outdoor, or extreme settings.

- Material needs: Selecting metals like aluminum for lightweight parts or titanium for added strength.

At YL-Machining, we value this discovery phase. By clarifying requirements upfront, we reduce the risk of costly errors later.

2. Advanced CAD Design

Night vision camera parts often involve intricate geometries and tight tolerances. Using state-of-the-art CAD software, we transform your vision into detailed 3D models.

- Accurate measurements: Models include exact specifications to avoid alignment issues.

- Simulation tools: Test how the part will perform under stress, vibration, or temperature changes.

- Rapid revisions: Easily tweak designs to incorporate client feedback.

This phase ensures the design is production-ready and aligns with the functional needs of night vision technology.

3. Selecting the Best Materials for Night Vision Applications

Material selection is critical in ensuring the performance of night vision camera parts. CNC machining offers unparalleled versatility when it comes to material options:

- Aluminum: Lightweight and corrosion-resistant, ideal for housing components.

- Stainless Steel: For applications requiring strength and resistance to environmental factors.

- Plastics: Materials like Delrin or ABS for non-conductive or lightweight elements.

Using the right material can make the difference between a durable, reliable component and one that fails under pressure.

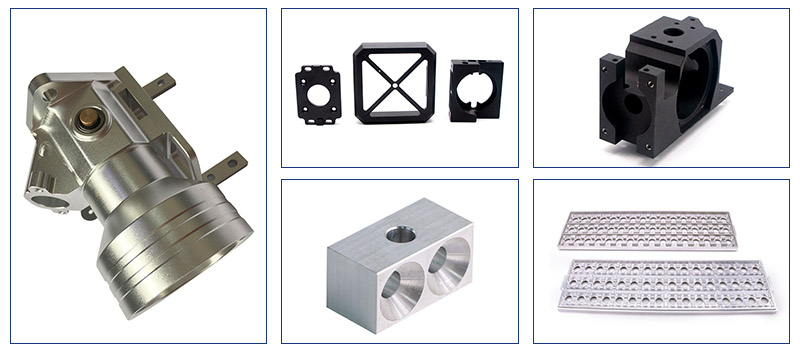

4. Precision Machining

This is where the magic happens. CNC machines cut, drill, and shape materials to bring the design to life. With 5-axis CNC machining, even the most complex geometries can be achieved with high accuracy.

- Tight tolerances: CNC machining ensures components meet specifications down to microns.

- Complex cuts: Create intricate shapes like mounting slots, lens housings, or threaded inserts.

- Efficiency: Modern CNC machines minimize waste while maximizing precision.

For night vision camera parts, precision is non-negotiable, and our CNC machines are up to the task.

5. Prototyping and Testing

Low-volume production is perfect for prototyping. A prototype lets you test the part in real-world conditions before committing to a larger batch.

- Functional testing: Evaluate the part’s fit and performance within the camera system.

- Iterative improvements: Make adjustments based on testing feedback.

- Cost-effective refinement: CNC machining allows quick and affordable iterations.

One of our clients required a custom lens housing for a night vision camera. After the first prototype, we adjusted the threading to improve assembly—a small change that made a big impact.

6. Surface Finishing and Coating

Night vision camera components often require specialized finishes to improve their performance:

- Anodizing: For enhanced corrosion resistance and a sleek appearance.

- Powder coating: Adds a durable, scratch-resistant layer.

- Polishing: Achieves a smooth, reflective surface for optical parts.

These finishing processes not only improve the component’s durability but also ensure it meets the aesthetic and functional standards of high-end night vision systems.

7. Rigorous Quality Control

Every part we produce undergoes stringent quality control checks to ensure it meets specifications. For night vision camera components, this step is especially critical.

- Dimensional inspection: Using precision measurement tools like CMMs to verify tolerances.

- Material testing: Ensuring the chosen material performs as expected.

- Performance evaluation: Simulating real-world conditions to test durability and functionality.

Our commitment to quality ensures that every part leaving YL-Machining is production-ready and reliable.

Benefits of Low-Volume CNC Machining for Night Vision Camera Parts

Choosing low-volume CNC customization offers unique advantages for manufacturers:

- Quick Turnarounds: Rapid prototyping and production keep your project on schedule.

- Cost Savings: Avoiding high tooling costs makes small batches more economical.

- Design Flexibility: Easily refine or iterate designs without expensive rework.

- Precision and Consistency: Each part meets exacting standards for high-performance applications.

For complex, high-stakes components like those in night vision cameras, these benefits are invaluable.

How YL-Machining Stands Out in CNC Customization

At YL-Machining, we understand the unique challenges of producing night vision camera parts. Here’s what sets us apart:

- Expertise: Decades of experience in CNC machining for optical and electronic components.

- Advanced Technology: Cutting-edge equipment for precision and efficiency.

- Customer Collaboration: We work closely with clients to meet their exact needs.

- Commitment to Quality: Every component undergoes rigorous testing and inspection.

Conclusion: Partner with YL-Machining for Your Custom CNC Needs

Whether you’re developing a new night vision camera or refining an existing design, low-volume CNC customization offers unmatched flexibility, precision, and cost-effectiveness. At YL-Machining, we’re dedicated to helping you achieve your vision with high-quality, reliable parts.

Let’s discuss your next project—contact us today to get started!