Opening: The Magic of Machining

Did you know that the world of CNC machining has evolved so much that it can now achieve surface finishes that are smoother than a baby’s skin? With advancements in technology and techniques, CNC machining is not just about cutting and shaping materials—it is also capable of surface polishing parts made from various metals and plastics. As industries demand higher precision and better performance from their machined components, the ability to combine machining with surface finishing processes has become a defining factor in maintaining competitiveness.

Understanding CNC Machining and Surface Polishing

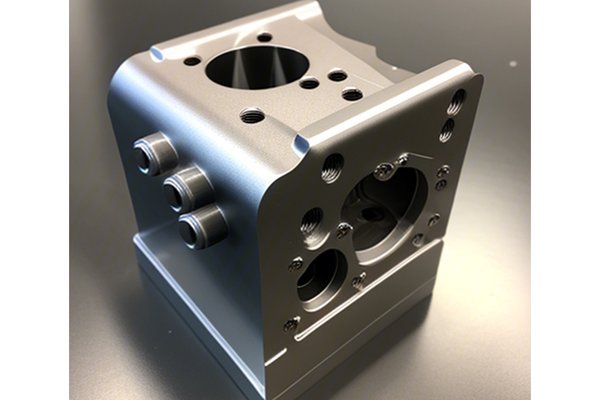

Computer Numerical Control (CNC) machining involves using pre-programmed software to control the movement of machinery, allowing for the incredible accuracy and efficiency associated with modern manufacturing. In addition to its cutting capabilities, CNC machines can be equipped with specialized tools that enable them to perform surface polishing. This process is essential for enhancing both the aesthetic appeal and the functional performance of parts that will be used in sensitive applications.

Surface polishing entails refining and smoothing the surface of a material to reduce roughness, increase corrosion resistance, enhance visibility, and improve the overall quality of the finished product. It is particularly vital in industries such as aerospace, automotive, and medical, where component performance can significantly affect the safety and functionality of any system.

Surface Polishing Methods in CNC Machining

Mechanical polishing is one of the most common methods utilized in CNC machining. It involves using abrasive materials, such as cloths or pads, combined with polishing compounds to mechanically smooth the surfaces of components. The CNC machine can be programmed to perform this process at different speeds and directions to achieve the desired surface finish.

Electropolishing is an electrochemical process that removes material from a metallic workpiece to achieve a fine surface finish. This method is particularly effective for stainless steel and can dramatically enhance the corrosion resistance of the component being processed.

Ultrasonic polishing uses high-frequency acoustic waves to produce micro-vibrations in a polishing fluid. This fluid, often with abrasive particles suspended in it, can reach intricate geometries and produce high-quality finishes on complex parts.

Vibratory finishing typically involves placing parts along with media (abrasives) in a vibrating bowl. This method is particularly useful for polishing multiple parts simultaneously.

Choosing the Right Method for Surface Polishing

Selecting the appropriate surface polishing method depends on various factors, such as:

Challenges in CNC Surface Polishing

While the advancements in CNC technology and techniques have opened up new possibilities for polishing parts, several challenges need to be addressed:

Best Practices for Successful CNC Surface Polishing

: The Importance of CNC Surface Polishing in Manufacturing

In conclusion, CNC machining has introduced groundbreaking capabilities for not just machining but also surface polishing of various metal and plastic parts. Understanding the methods available, such as mechanical polishing, electropolishing, ultrasonic polishing, and vibratory finishing, allows manufacturers to choose the right approach tailored to their unique projects.

Beyond just aesthetics, effective surface polishing enhances performance, adds corrosion resistance, and delivers reliability—attributes that are paramount in critical applications across multiple industries. As manufacturing continues to push boundaries, the importance of CNC surface polishing cannot be overstated. It is essential for producers to stay informed about technological advancements in this area, as the combination of precision and surface treatment remains a vital pillar of successful modern manufacturing.

Remember, whether you are an engineer, a business owner, or a manufacturing specialist, the right polishing techniques are key to elevating your product’s performance and market success. Consider this blog as your stepping stone in understanding the crucial interplay between CNC capabilities and surface finishing processes, ensuring your products are not just made but made to perfection.